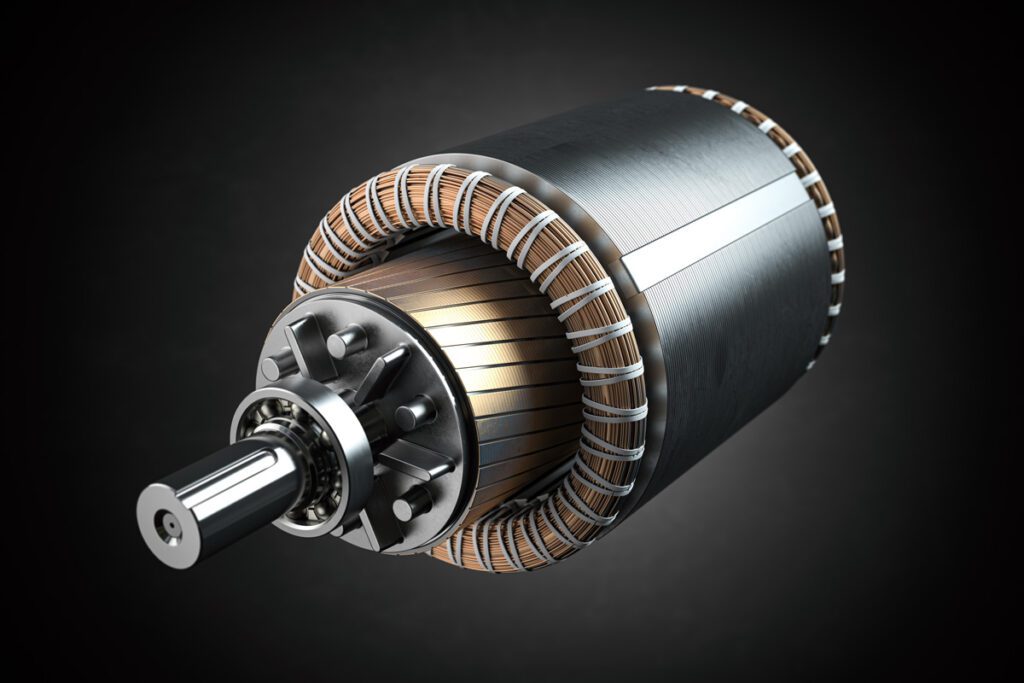

ExOne, an industrial sand and metal 3D printing company, is collaborating with Tennessee-based startup Maxxwell Motors to develop a copper e-winding design for its axial flux electric motors. The two companies have successfully 3D printed a high-efficiency copper e-winding design for an electric motor without rare earth magnets, eliminating some challenges that come from traditional copper manufacturing. The 3D printing process could eliminate the need for coil wrapping, bending, tooling and welding individual parts together.

“When we 3D print it, a lot of the challenges just go away, and we can actually improve the performance of the motor itself,” said Michael Paritee, CEO of Maxxwell Motors. “At Maxxwell, we’re taking the most sustainable point of view possible to improve efficiency, reduce waste and optimize performance.”

Maxxwell says producing parts with binder-jet 3D printing requires fewer manufacturing steps and less energy utilization, and generates less material waste. It also results in components that are more efficient and deliver improved performance. What’s more, high-speed binder jetting is relatively affordable.

Source: ExOne