In a €4-million HEFT research project directed by Mondragan University, eight EU partners including GKN Automotive will create a “lower-cost, more efficient and power-dense” permanent magnet motor for EVs.

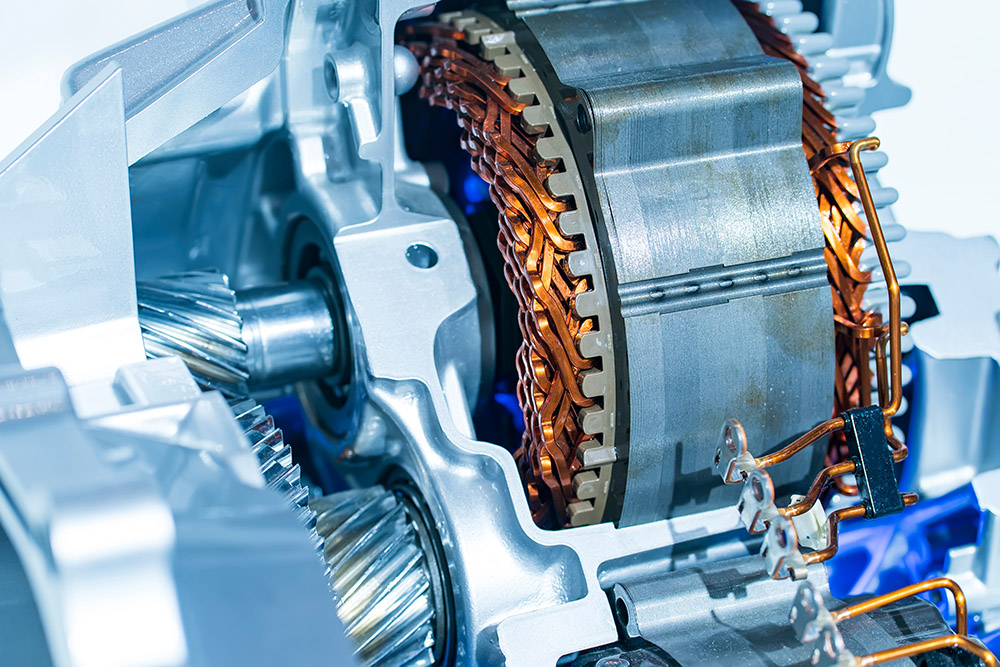

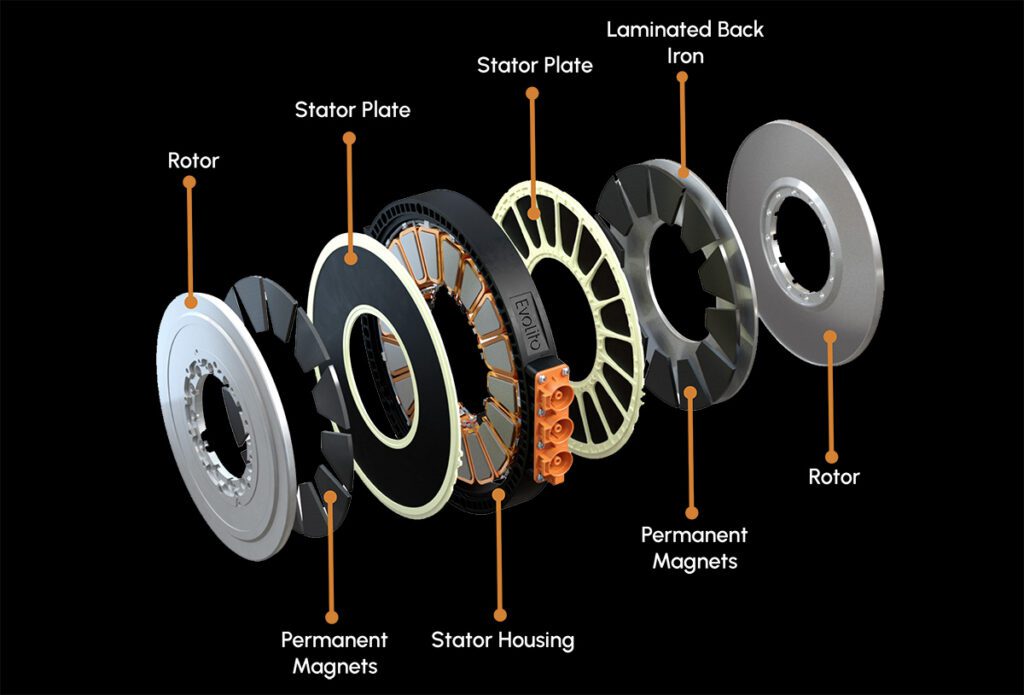

HEFT is an EU Horizon 2020 project focused on designing and manufacturing EV motors with reused and recycled permanent magnets. HEFT recommends energy-efficient rare earth synchronous motors for next-generation high-power primary axle traction EVs. The project proposes challenges on electric synchronous motor configuration based on SiC inverters (direct cooling of rotor and stator, advance insulation for high voltage, multibarrier rotor topology, wave windings) and advanced materials (advanced GBD magnets, epoxy for magnet fixation, composite for motor housing, insulation resin).

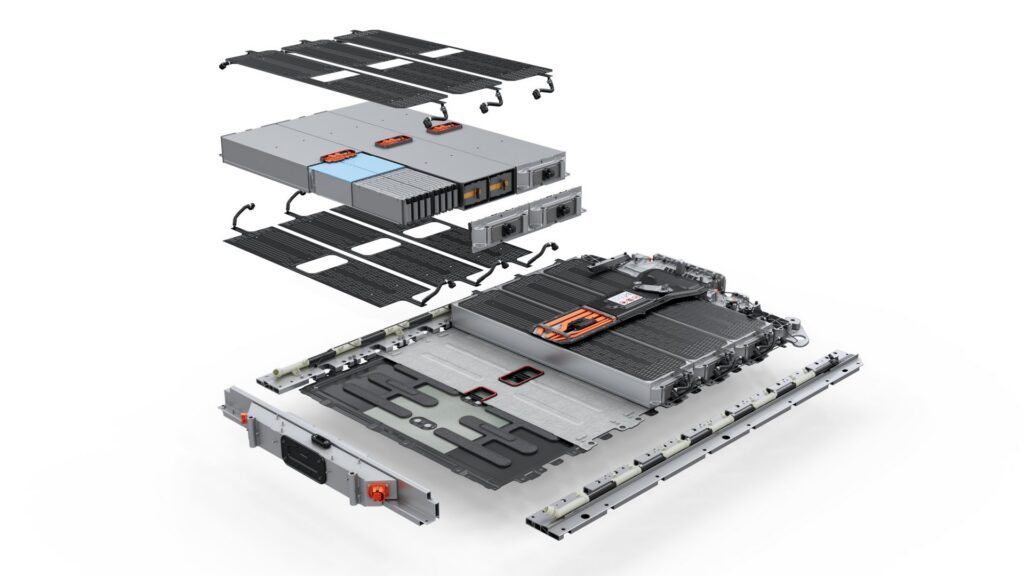

The aim is to produce a high-efficiency, low-cost solution that will be evaluated on two motor topologies and compared to two reference vehicle interior permanent magnet (IPM) commercial motors in Europe—the VW ID.3 and Fiat 500. They are expected to result in >800 V, 20% reduction losses, >7 kW/kg and 42 kW/l power density, 28% cost savings, 50-66% material savings, 60% reduction of rare earth element (REE) content and >80% REE recyclability.

HEFT will be connected with the European Raw Materials Alliance (ERMA) action plan towards a circular economy market of rare earth permanent magnets. It will offer one alternative cerium-based magnet route and two REE recycling pathways, as well as strategies to establish a European rare earths industry.

Source: Green Car Congress