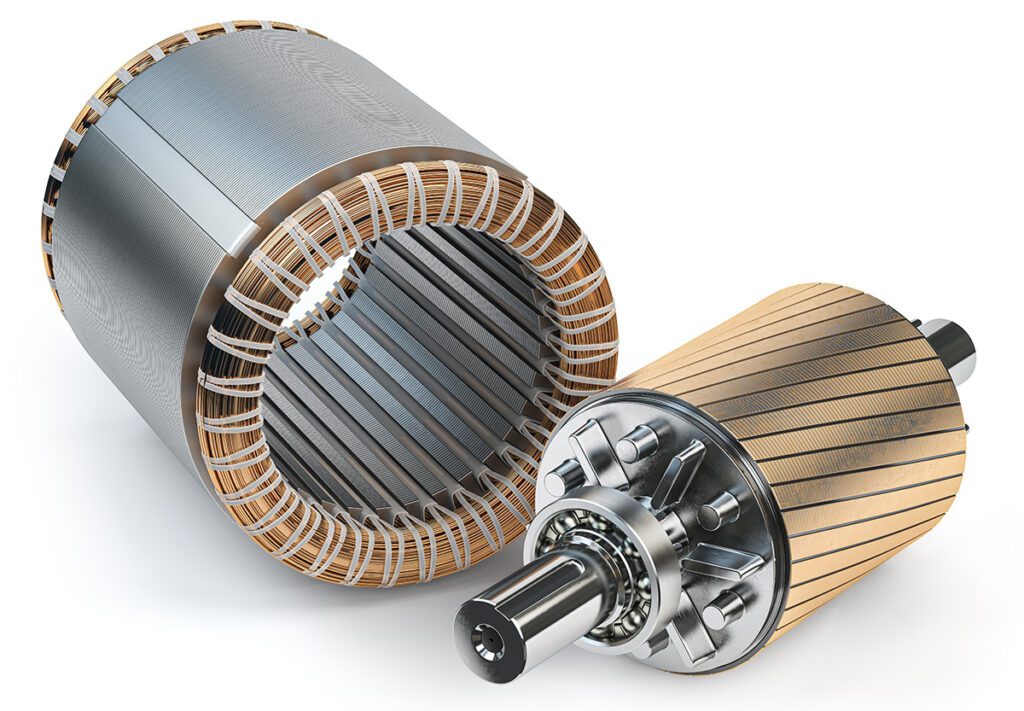

Electric powertrain manufacturer Equipmake has teamed up with additive manufacturing company HiETA Technologies to develop a next-generation motor, codenamed AMPERE. The project is the group’s attempt to produce a lightweight, efficient, low-cost electric motor with peak power density of more than 20 kW per kg. AMPERE is made using additive manufacturing, which allows its metal structure to be 3D printed rather than milled from a solid billet. This approach minimizes the amount of high-strength alloys and expensive materials needed for the magnets.

Equipmake and HiETA are targeting a peak power of 220 kW at 30,000 rpm and a weight of less than 10 kg. By comparison, Equipmake’s APM 125, which uses the company’s spoke architecture to maximize cooling capability, offers peak power of 125 kW at 12,000 rpm and a weight of 14 kg, giving it a power density of just under 9 kW per kg.

Ian Foley, Managing Director of Equipmake, said, “Additive manufacturing is the key to unlocking the next step change, and we are delighted to be partnering with HiETA on AMPERE. This exciting project has the potential to totally change our concept of what an electric motor can offer—and with such a huge amount of performance in such a small package at as low a cost as possible.”

The first AMPERE prototypes are set to be up and running in 12 months’ time.

Source: Equipmake