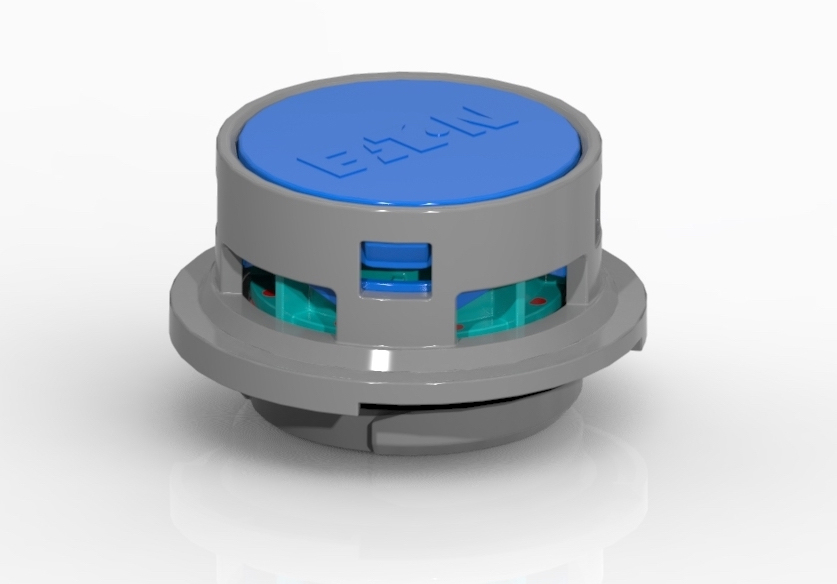

Power management company Eaton has introduced a 3-in-1 battery pack vent valve for EV batteries. The valve is capable of three functions: battery case leak-checking, and both passive and active venting to provide battery pack overpressure relief.

The company says the leak-check mechanism eliminates the need to install the vent valve as the final step of battery assembly and that leak testing is more thorough because it includes testing the sealing surface of the vent after the vent valve has been assembled.

Eaton has also developed a tool that allows manufacturers to actuate the leak-check mechanism on their assembly lines to permit testing through pressurization or a vacuum. Its spring-based actuation accommodates a range of opening pressure requirements with the same valve design, driving economies of scale.

The valve features a low-flow breathing mode that allows air to move through porous material to normalize pressure during regular operation, and its resealing technology enables manufacturers to specify very low opening pressures. “Our new battery vent valve can be assembled both through our robust quick-connect feature or by a screwed metal-to-metal connection,” said Eaton Manager Jens Buhlinger.

Source: Eaton