Under a project sponsored by the German Ministry for Economic Affairs and Energy, Daimler and the Fraunhofer Institute, together with German conglomerate thyssenkrupp and engineering firm IAV, are co-developing the design and production of bipolar batteries.

Bipolar batteries are still in the laboratory stage and have not moved past pilot scale. The project, named EMBATT-goes-FAB, aims to bring these batteries to production.

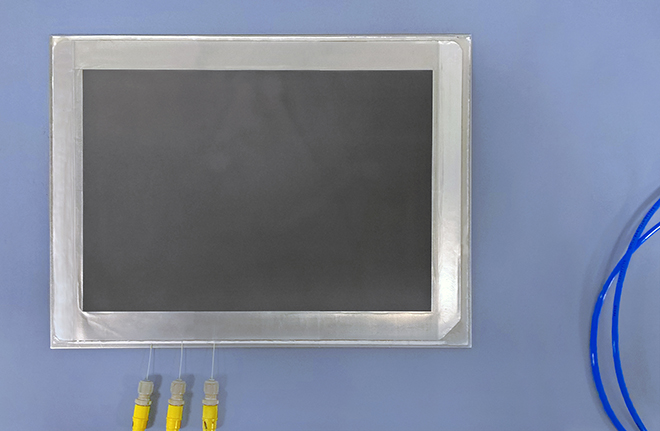

In contrast to conventional Li-ion batteries, bipolar batteries have stacked electrodes connected in series. The active materials for the battery cathode and anode are applied to a common electrode carrier.

The individual Li-ion cells are not packed in separate aluminum housings – only the finished stack of electrodes is given a fixed housing. By eliminating housing components and connecting materials, EMBATT-goes-FAB aims to shave costs and save space within vehicles.

Fraunhofer will produce bipolar electrodes based on lithium-nickel-manganese-cobalt oxides and graphite as storage materials. Thyssenkrupp will scale the battery up to a size of 1,000 x 30 square cm. IAV will incorporate a battery monitoring system and Daimler will perform safety simulations.

Source: Fraunhofer Institute