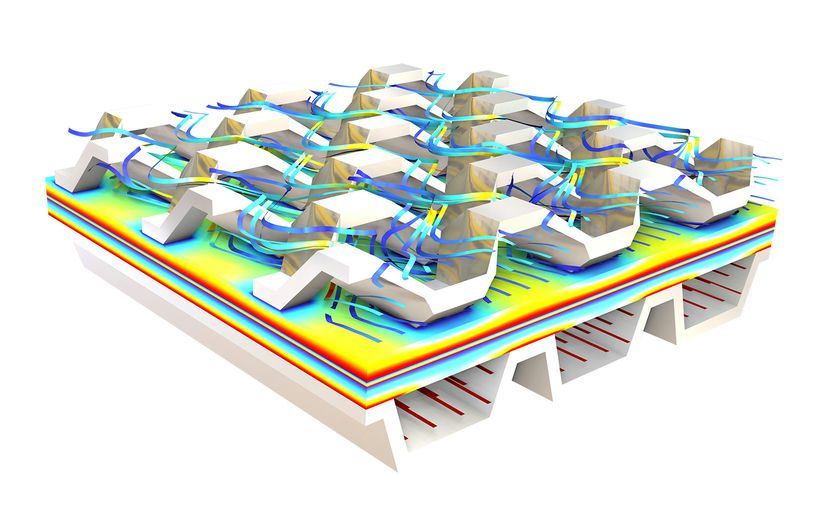

BW Papersystems (BWP), LiCAP Technologies (LiCAP) and Siemens have formed a strategic partnership to manufacture dry electrode systems for batteries.

The partnership aims to industrialize LiCAP’s Activated Dry Electrode technology by using BWP’s and Siemens’s resources. Siemens will help to scale production for both companies.

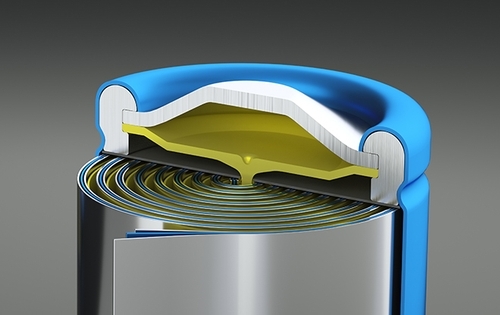

According to LiCAP, its Activated Dry Electrode technology enables the safe and reliable operation of ultracapacitor electrodes at 3 V compared to electrodes manufactured via the traditional “wet” coating process, which operate between 2.7 and 2.85 V.

“For LiCAP, it was important that BWP and Siemens, as our manufacturing partners, already have the expertise and know-how in areas that are critical to successful commercialization of our Activated Dry Electrode technology,” says Martin Zea, VP of Operations at LiCAP. “This is why we partnered up with them and have no doubt they can build manufacturing equipment for our electrode manufacturing process at a much greater speed compared to any other company,”

Source: LiCAP