Before a lithium-ion battery is installed in a vehicle, it must undergo a lengthy process called formation, in which it is charged and discharged to control the initial chemical reactions with lithium. Many of these reactions are irreversible and permanently decrease the battery’s available energy. The process requires expensive lithium to be part of the cathode, and it significantly increases manufacturing time. Finding a way to reduce or eliminate this process could substantially reduce the overall cost of Li-ion batteries.

Researchers have tried to eliminate the formation process by adding extra lithium to the battery anode in a procedure called prelithiation. Ideally, prelithiation must be compatible with aqueous slurry processing and not introduce additional steps.

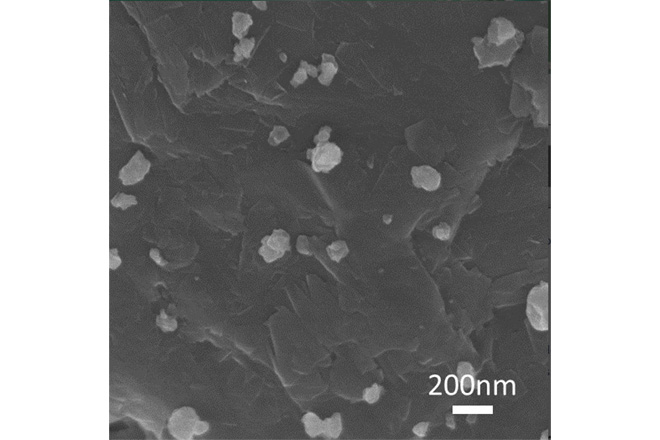

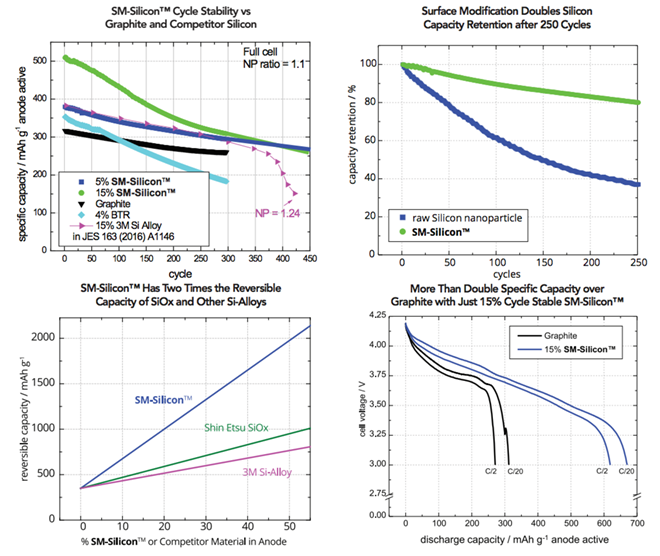

Paraclete Energy has introduced new methods that are designed to ensure aqueous compatibility by preventing the violent chemical reactions typically seen with prelithiated materials. Also, electrochemical cycling can be improved by using Paraclete’s SM-Silicon family of surface-modified products, which acts as an artificial solid electrolyte interphase (SEI) to limit undesirable side reactions. According to Paraclete, its technology is fully compatible with aqueous slurries and does not add additional processing.

Paraclete Energy has now released a prelithiated SM-Silicon product, SM-Silicon/PL, which has a proprietary surface modifier that acts as a protective shell from air and moisture, as well as an artificial SEI for cycle stability.

“Prelithiation is very appealing,” said Jeff Norris, CEO of Paraclete Energy, “because, unlike many standard battery improvement techniques which fight for a fraction-of-a-percent performance increase, any percentage gain from prelithiation is gained as a 1:1 ratio towards overall battery energy density. With adequate prelithiation, minimal formation cycles will be required, cutting the time to manufacture batteries significantly, which [will reduce costs and increase] the manufacturing capacity of a facility. Prelithiation should bring about a cost-reduction shift across the entire industry.”

Source: Paraclete Energy