Researchers at the US Department of Energy’s Argonne National Laboratory have developed a method to coat sulfide-based solid electrolytes to improve chemical stability and reduce manufacturing costs.

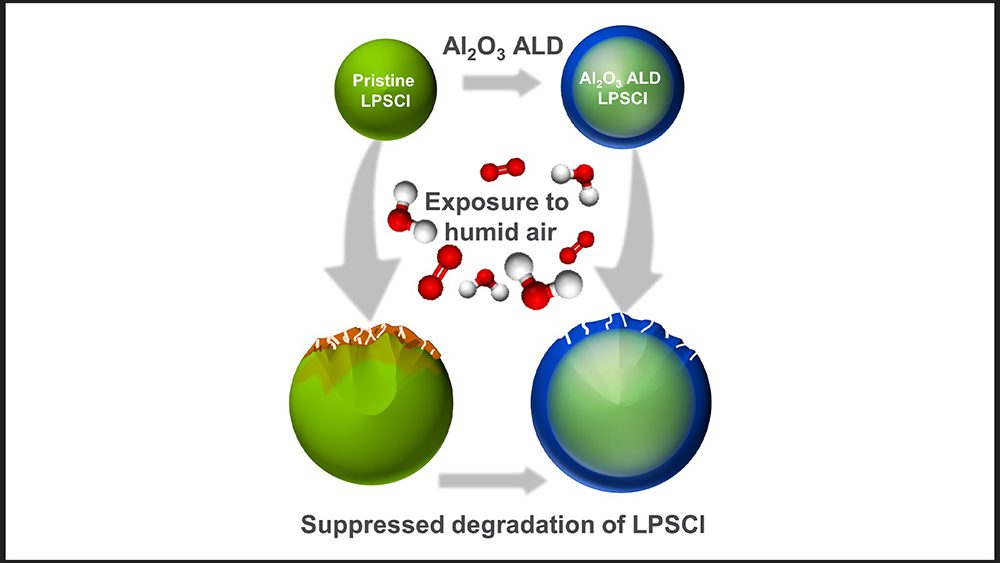

The process uses atomic layer deposition (ALD) to apply a protective layer of aluminum oxide onto the electrolyte particles. This coating improves stability by acting as a shield and modifying the surface’s electronic structure.

In tests under conditions where there were levels of high humidity and oxygen, the coated electrolytes outperformed uncoated electrolytes, remaining stable with little degradation. This addresses a key challenge for solid-state batteries, as electrolytes can break down when exposed to humidity and oxygen. This is particularly the case for high-performance, sulfide-based solid electrolytes such as lithium phosphorus sulfur chloride (LPSCl), according to the researchers. Producing solid-state batteries using these materials requires maintaining a dry room below -40° C, which drives up production costs.

“Our research shows that even a very thin coating—just a few nanometers thick— can act as a strong barrier, keeping the electrolyte intact and boosting its performance,” said Argonne Materials Scientist Justin Connell. “This breakthrough can extend battery life and lower manufacturing costs by allowing production in less controlled environments.”

The research team is working to scale up this method and is collaborating with a commercial partner to produce larger quantities of the coated electrolyte for demonstration in larger-format batteries. Future research will focus on exploring other coating chemistries.

Source: Argonne National Laboratory