Dry-electrode pioneer AM Batteries (AMB) and battery producer Amperex Technology Limited (ATL) have teamed up to develop solvent-free electrode manufacturing technology.

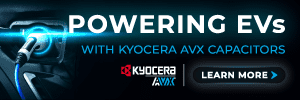

AMB has developed a unique electrostatic spray deposition technique by which dry cathode and anode electrode materials are electrostatically charged and deposited onto metal-foil current collectors, which are then processed to their final state without the use of toxic solvents. The company says this innovation can save energy, reduce capital expenses for electrode-coating equipment, and shrink the physical footprint of required infrastructure.

AMB says its dry process opens up additional avenues for customization, which can enable the production of faster-charging, more energy-dense, safer batteries. In collaboration with ATL’s production experts, AMB hopes to further develop its process to integrate it into full-scale production applications.

“One of the fundamental problems for battery manufacturers is refining manufacturing techniques to remove the solvents used in wet coating of electrodes,” said AMB CEO Yan Wang. “Our dry-electrode manufacturing technology allows for the coating of lithium-ion battery electrodes without the need for any solvents or energy-intensive evaporation.”

“We see the need for improvements in battery manufacturing in regard to cost, scale, and environmental impact issues,” said Joe Kit Chu Lam, ATL Executive Vice President. “AMB’s electrostatic spray technology directly addresses these challenges.”

Source: AM Batteries