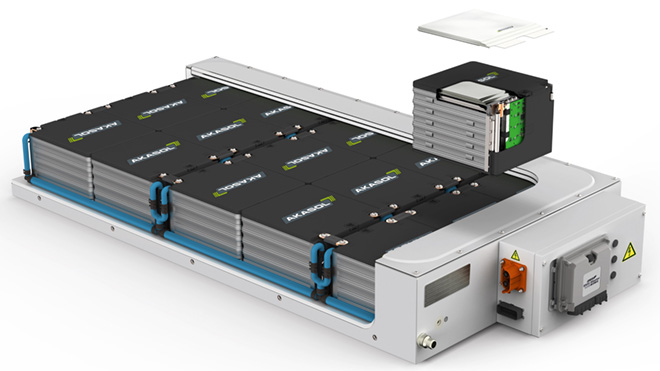

German battery builder AKASOL has built two new production sites: a new facility with over 3,000 square meters of production halls and office space in Langen, as well as an additional 700 square meters of production space at the company’s headquarters in Darmstadt.

The automated production line in Langen will be set up by the end of 2017, and starting in 2018, up to 150 members of staff will begin series assembly of lithium-ion battery systems for European bus manufacturers. The plant will have a total capacity of up to 300 MWh, enough to equip about 1,500 e-buses annually. The company plans to expand capacity to up to 600 MWh per year in a second phase.

At the new plant in Darmstadt, small-scale series production for orders in the commercial vehicle, railway and marine industries has already begun.

Both facilities were designed to be sustainable, and were built to the latest standards. The German Sustainable Building Council certified the building according to the 40 DGNB Gold standard, which represents the highest level of sustainability.

“We are delighted to have found the ideal production and working conditions for series manufacturing in the direct vicinity of our Darmstadt headquarters thanks to the Multipark Langen,” says Sven Schulz, CEO of AKASOL. “Our second plant in Darmstadt will allow us to add further capacity for small-scale series production. Our customers will benefit from the scalable and industry-specific production capacities of our new facilities.”

MORE: AKASOL introduces modular battery packs for commercial vehicles

Source: AKASOL