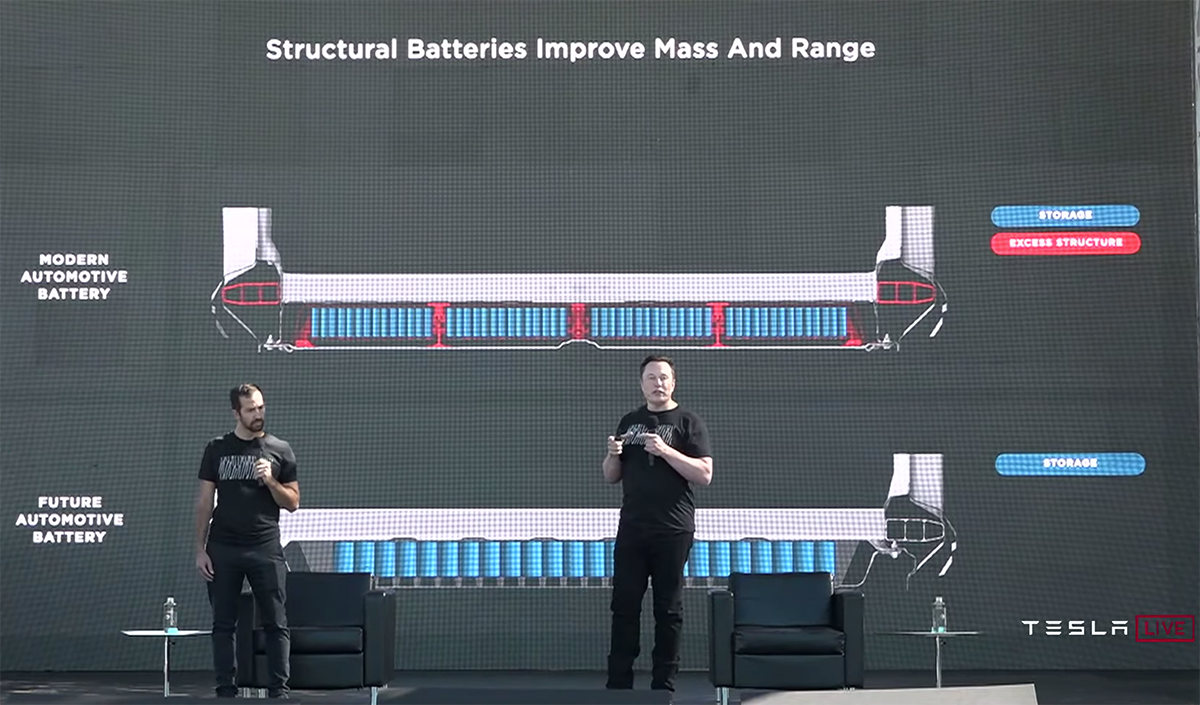

One of the most significant innovations Tesla introduced with Model Y was the replacement of about 70 parts with two enormous aluminum castings. Now the company says it has plans to take this idea a step further by developing a battery pack that forms part of the structure of the vehicle, linking the front and rear underbody castings. The new design will reduce the number of parts and the weight of the battery pack.

The concept is familiar in aerospace applications, in which weight is all-important (airplane wings do double duty as fuel tanks), but although automotive researchers have experimented with the idea of incorporating batteries into body parts, Tesla appears to be the first to put it into practice.

Now Electrek has got hold of a picture of Tesla’s new structural battery pack. It’s based on a honeycomb architecture, which is known for high strength and low weight, and has been used for various applications in the aerospace and automotive fields. The new pack does not use modules—apparently, Tesla’s new 4680 battery cells will be inserted directly into the structural cells of the honeycomb. Coolant loops snake around the sides of the pack.

“Battery pack will be a bonded structure with cells providing shear transfer between steel upper and lower face sheets, eliminating most of the center body parts while providing better torsional rigidity and improved polar moment or inertia,” said Elon Musk. “This is a major breakthrough.”

Musk also recently discussed some details of the new battery pack with auto manufacturing expert Sandy Munro (around 22:15 in the video below).

Source: Electrek