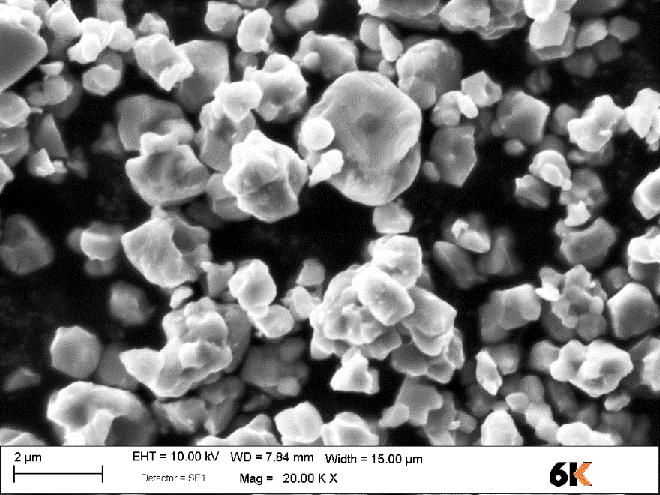

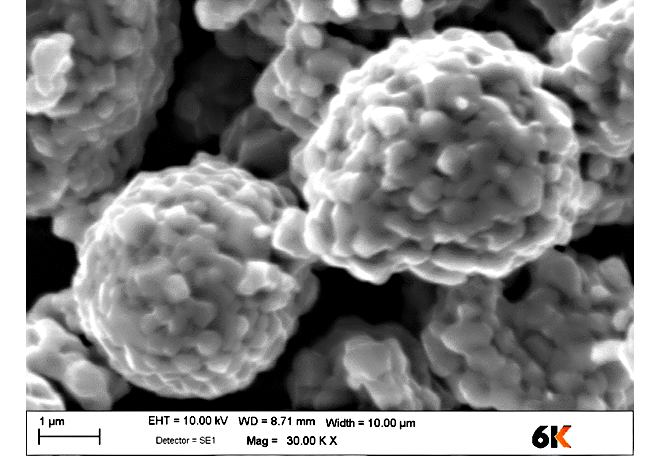

6K announced that it has developed NMC 811 at 1-3 microns as well as the capability to produce single-crystal NMC. Smaller size ranges, desired in the industry but challenging to achieve with conventional methods, improve charge time, extend run time and increase power. 6K has received strong customer pull at all levels of the supply chain for a cost-effective solution for small-particle high-nickel cathodes such as NMC 811. Low-cost sources of these materials are needed to maximize the energy density of EV batteries via bimodal size distributions, and to improve power in portable applications. 6K says it can use its UniMelt platform to produce single-crystal NMC without the multiple additional material- and energy-intensive steps required by standard methods.

“We are responding directly to strong demand we’ve had from multiple iconic brand customers in the EV and consumer battery markets who are seeking higher nickel content and smaller size NMC,” said VP Dr. Richard Holman. “In less than 3 months, our team was able to adapt the NMC-622 process to produce NMC-811 at over 200 mAh/g, and dial in sizes from 1-3 microns. What is a challenge for standard co-precipitation is relatively easy for 6K Energy, which underscores the power of the UniMelt production process.”

Source: 6K