Bollinger Motors is not following the typical EV startup formula. Instead of building a luxury sedan, it’s building a rough and ready work truck. It has no strategy to evolve into a mass-market automaker, but intends to find a niche as a low-volume brand. As far as we know, the company has no former Tesla executives and no deep-pocketed Chinese investors – two common components of most recent EV startups.

What it does have is a working prototype of a “no-nonsense back-to-basics all-electric sport utility truck” that fills a glaring gap in the current EV market. The B1 claims to seat four passengers comfortably and some will find it stylish, in a retro safari kind of way, but it’s built for the farm or job site, not for the suburban soccer set. It’s designed to haul large, heavy objects, and plenty of them. The yawning rear opening can accommodate 4×8 boards – up to 72 sheets of half-inch plywood. A unique pass-through arrangement makes it easy to haul really long items (up to 24 2x4s) – there’s a front liftgate, and the rear seats fold up and out of the way. The B1 is also suitable for off-road adventure, with AWD, a hydraulic winch and a ground clearance of up to 15.5 inches.

For Robert Bollinger, the company is the fulfillment of a lifelong dream. He studied industrial design in college, and planned to be an automotive designer. However, he went on to have a successful career in marketing and design, outside of the automotive field. Later he helped to build a business, and sold it at a profit, giving him the funds to revive his childhood dream and start up Bollinger Motors. “It was kind of like a long crazy journey to get here,” Bollinger says, “but I wouldn’t change a thing, so here we are.”

Charged chatted with Bollinger about the vehicle, the company and the business plan, and we present his comments here in his own words, lightly edited for clarity and brevity.

Charged: Are you solely self-funded? And what’s the plan for the future? Are you going to be raising money?

Robert Bollinger: Yeah, we’re solely self-funded right now, and we’re covered for a couple more years. Our business plan as we have it right now is that we’ll take deposits from the first customers, and that’ll fund us also. At some point, we’ll be doing the investor thing, probably. Right now, what’s good is that we can concentrate on the engineering and not have to really answer to anybody. We’re just doing our own thing, and we have a plan where that can work out for a while.

Charged: Are the parts that you used to build the B1 prototype intended to be the production parts, or are those things you’re going to source out in the future?

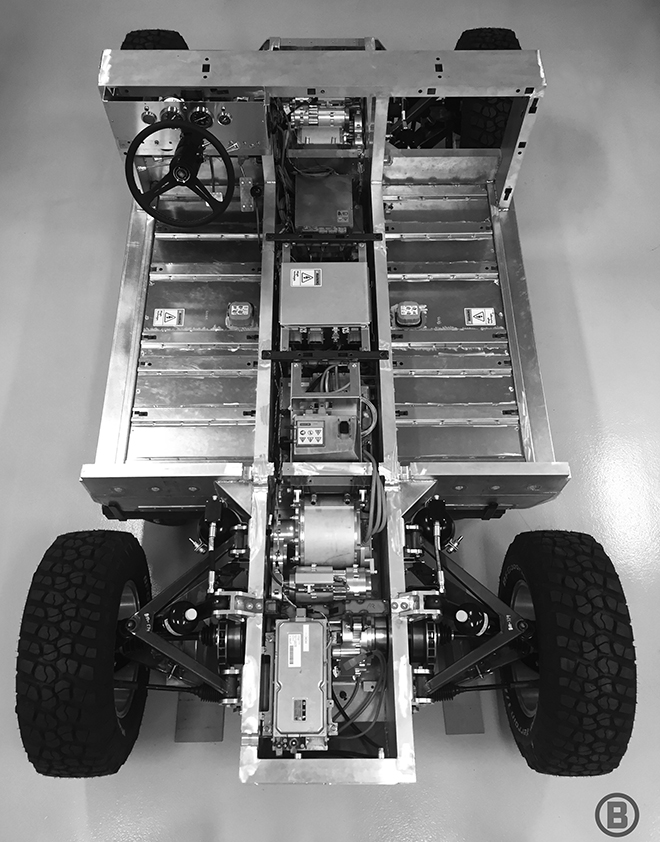

Robert Bollinger: From the very beginning, because we always wanted to be working in an efficient way, and not have to go back, our goal was to make the whole truck, from the ground up, exactly the way we wanted it. Through CAD, everything’s engineered to every single micron. There are parts that we wanted to engineer ourselves, and design to our own specs, like the gearboxes, the chassis and the body. Then, things like headlights and turn lights, and stuff like that, are off the shelf, from vendors. So, everything was intended from the very beginning as production-ready. Our first prototype, which is the one you see in all the videos, is a fully working proof of concept. Our new partner in the Detroit area, Optimal, is an engineering firm that does tons of simulation, lightweighting, benchmarking, all this kind of stuff. So through them, we now take it to the next step.

There’ll be a number of changes to improve it, like wherever we can save weight, and make things stronger, and more efficient…then we’ll have another prototype later. But yeah, the idea from the beginning was always to make it exactly how it would be produced. So we didn’t just hand-craft something together and say, “We’ll figure it out later.” We figured it out as we went.

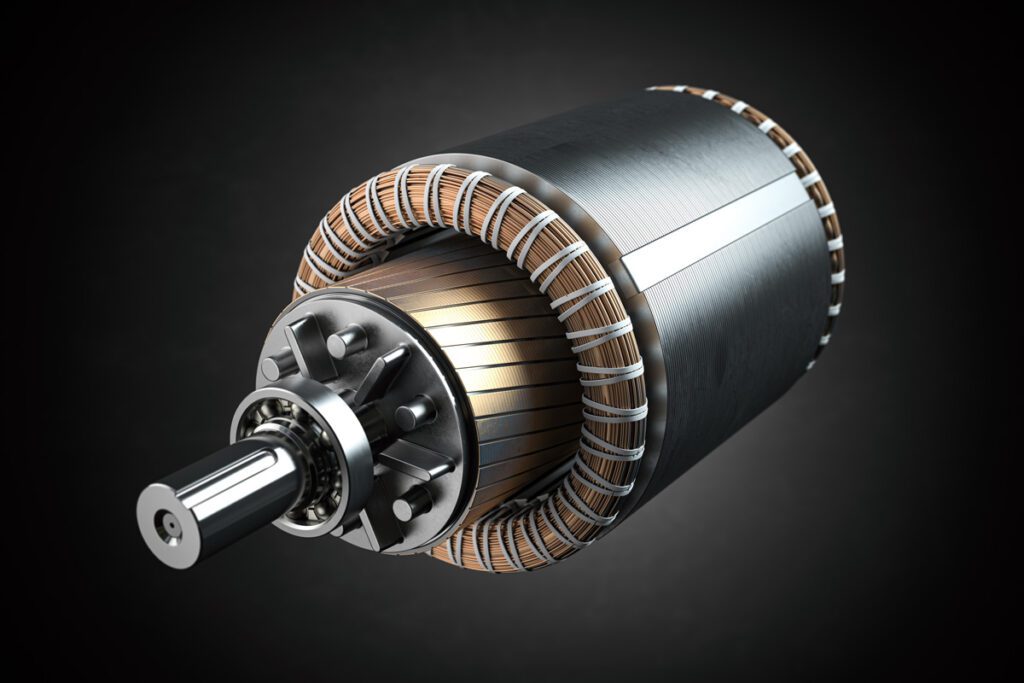

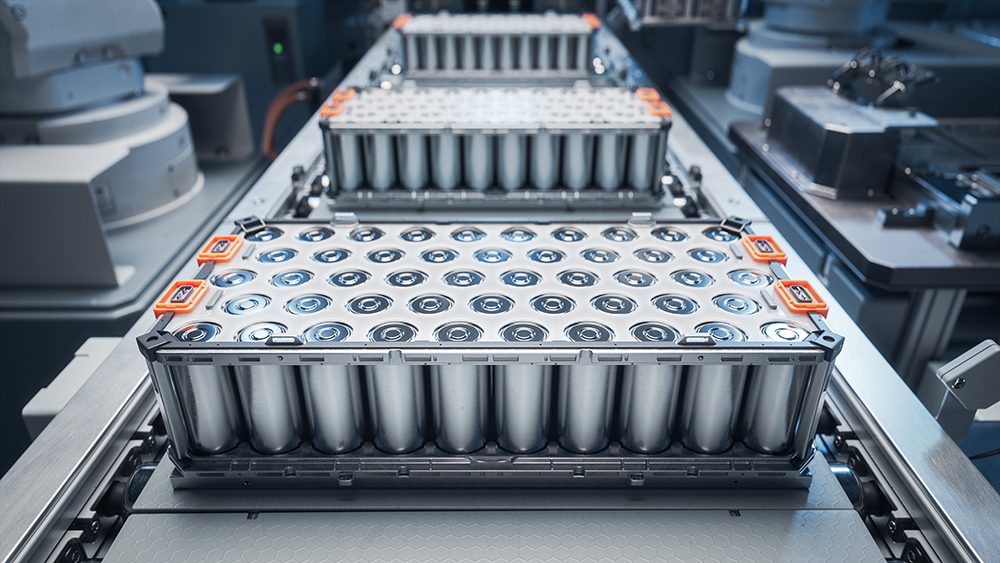

Charged: So what about the EV-specific stuff? The battery cells, the motor and the motor controller? Are those things that could change in the future as well?

Robert Bollinger: Yeah. For this prototype, we have battery cells from one vendor, but we’re changing our vendor for the production version, for a more power-dense battery cell. Like pretty much all EV makers, we buy our battery cells from a third-party company. Our IP, our own design of how we put them together, how we write the software to control those battery cells, what size we want the battery pack to be, all that kind of stuff, we’re creating. So in the next iteration, we’re going for a 120 kWh pack, which is really big. There’s really nothing out on the road that’s that size right now. That’s a lot of mass. That’s a lot of stuff to control. That’s a lot of work. But that’s what we want to have for range, and for the ability to use the truck in all the different ways that we want it to be used.

Say 10 years from now battery chemistry changes dramatically. We can update that. It’s not as simple as switching them out, but the way our battery packs will be – on the bottom’s a popular way to do it – we’ll be able to take off that battery pack, and [update it] with the new kind of battery cells that come along.

Charged: Do you mean you’ll update customer’s cars?

Robert Bollinger: We’ll have to see what kind of thing happens in the future. Say 10 years from now batteries are half as expensive and half as heavy, but twice as powerful. We’ll definitely have customers that’ll be like, “Hey, we want one of those!” So I’m sure we’ll do some kind of battery pack upgrade that you can buy. The idea is that, this truck being aluminum, and really well protected with paint against corrosion of any type, you buy the B1 and keep it for the rest of your life. So if you have it for 20 years, 30 years, hopefully the batteries just keep chugging along, you don’t need to do anything with them. But if there’s any major breakthrough, we can deal with it.

Charged: It seems like a super-unique approach to building an automotive company. Is there some model that you can point to and say, “It worked for them?” Is there another car company that has the volume and the approach that you’re looking to emulate?

Robert Bollinger: At first, I had really big volume numbers, vehicles per year [in mind]. But as I learned more and more, I’m like, the main goal is to get it made, right? What helps us get it made? What volume? How many different kinds of options? So, really, ultra-low-volume manufacturers is the world that we’re in with. It’s kind of like how Tesla first came out with the Roadster, how they only made a few thousand of those at first.

Charged: Do you envision a time when you will want to take a leap into a higher volume?

Robert Bollinger: It’s funny…I don’t know why Tesla wanted to rush into the $35,000 range, which is very hard for them to make that car for and make a profit. No, we’re not looking up to 50,000 or 100,000, anything like that. We definitely want to stay at low volume. The plan for the next five years of production is to ramp up very slowly, and be very cautious about it.

Charged: Is success for you creating cool cars and a community that loves them? Is that a vision?

Robert Bollinger: Right. Yeah. There’s a lot of things I love about old Internationals, Defender 90s, and stuff like that, which kind of comes across in the look of our truck. But the Internationals were always super-low-volume compared to Ford [and] Chevy. At first, long ago, they were like the number-three truck maker. And then the other ones just took them over. I don’t think they intended to be low-volume, but I like the road of low-volume, especially with trucks – you’re doing something that the penny-pinchers aren’t going to let you do. I don’t ever want to be in that kind of camp – it’d be cool to always come up with something different.

Charged: So it’s a totally different business model than anyone else that you can think of.

Robert Bollinger: Yeah. Up here in the Catskills, where we created this whole thing, is such a community of craftsmanship – of craftsmen, and potters, and painters, and all that kind of stuff, so I can’t help but think it’s like we’re somewhere in between manufacturing and handcrafting, you know?

Charged: The idea of creating a low-volume car company seems very difficult, mostly because of the cost of regulations, warranties, service, etc. How do you plan to solve those challenges?

Robert Bollinger: We looked at the kit car thing early on, because we were wondering exactly the same thing. Where do we fit in the world of federal motor vehicle safety standards? And where we landed was a Class 3 truck, for many reasons. One is for the future trucks that we want to make off the same platform. Basically, what we want the B1 to be is, like the way Tesla made electric sexy, we’re making electric strong. This off-road truck has great ground clearance, can hold 5,000 pounds, all this kind of stuff. So, as a Class 3 truck, it lends itself to the kind of vehicles we want to make off of this in the future. But also, the regulations for Class 3 trucks don’t require air bags, and they don’t require physical crash testing. So, we’re doing simulated crash testing, and meeting all the regulations of a Class 3 truck. I think the reason the federal government has this variation in the regulations is that the Class 3 truck is kind of a low-volume world. And also, when you’re a Class 3 truck, you’re the strong one on the road. You’re safe in your truck, and it’s basically the small passenger cars that need the highly engineered crumple zones, to put it bluntly. So we’ve been doing our own due diligence, our own safety standards, but we are fully compliant with all federal regulations for safety standards for this truck.

Class 3 is 10,001 to 14,999 pound gross vehicle weight rating. Other Class 3 examples would be a Ford F-350 or Chevy 3500. Basically, what you’re doing is engineering the entire truck to handle 10,001 pounds. Our truck is going to end up being 5,000 pounds, probably, after all the batteries are in there. And so, you’ll be able to put 5,000 pounds in it, and it’ll still operate, and still adjust its suspension and handle, everything. And do all the braking regulations, in a certain amount of distance and all that kind of stuff. Towing is also a gear ratio thing, so towing capacity will probably be more than 5,000 pounds when we’re done.

In terms of warranty, the batteries will come with an eight-year warranty from the vendor. So we’ll have warranties from the people who supply us components. And we’re going to have to figure out our exact policy for the final warranty. But it will come with a pretty standard warranty for the industry.

We’re talking to third-party providers for service. There’s a lot of different ways to go there. You can go with a brand that has shops around – there’s a lot of them out there. There’s also this growing network of mom-and-pop corner shops that fix cars, that can get certified for electric. I really like that idea, because if it’s someone that you know, that you take your truck to already, in your town, if you could also take them the B1, that would be so cool.

Charged: What about your sales plan? Are you going to try to go through dealers?

Robert Bollinger: No. We’ll be so low-volume that it’ll be direct to the customer, like the Tesla model and some of the GoFundMe sites out there, where you pre-order stuff. And then we can deliver straight to the client, hopefully. That’s our plan – to ship it straight to you. Half of all EVs sell in California, so we’ll probably have an early presence there, a couple of stores or service centers.

Charged: The design is super-minimalized, particularly inside. What’s purposely not there that you’re used to finding in normal cars?

Robert Bollinger: Well, what’s purposely not there is a big computer screen that you are finding a lot in EVs. Our thing is, it’s a hands-on truck. You go off-road, you go do your work, throw your lumber in it, all that kind of thing. We’ll have air conditioning, we’ll have a radio, we’ll have comfortable seats, cup holders – that’ll be necessary. But the idea is that we’re bringing the truck back into it. A lot of SUVs start out as utility vehicles, but they’re really high-riding luxury sedans. But what if you want something rugged, that you can actually use? There aren’t that many options. And especially in electric, there’s none.

We’re purposely going anti-luxury. It’s not in a Spartan way, like it’s uncomfortable, but really just to go back to my aesthetic of what I like, which is just simple, straightforward. When I was doing the dashboard, I was like…completely flat across, and people were like, “Really?” And I was like, “Yeah, it’s going to be totally cool.” It has the screws right on there you can see, and you can unscrew it and take off your dashboard, and put in your own gauges if you want. If you trick the truck out with extra LED lights, you can put your switches right in there, so it’s customizable that way. We wanted to make it so it’s left-hand or right-hand drive capable on the production line. To keep everything as simple as possible is the main idea.

Charged: At what point do you think you’ll have an estimated MSRP?

Robert Bollinger: I’m really hoping to have our four-door prototype finished for a show this summer, and then announce pricing. But as we keep engineering it, we keep improving on it, and changing vendors here and there, so it’s hard to come up with your final price point. And if you announce that too soon, and you’re wrong, you could really mess yourself up, so we’re being very cautious.

Charged: Are you designing to a price point, or the opposite?

Robert Bollinger: We’re doing it the opposite way. What do we want in this vehicle? What would be the coolest truck? What are all the things we want in here? Dual motors, 120 kWh pack to give us at least a 200-mile range, and four-wheel gear hubs for the ground clearance, it’s going to add up. So we’re definitely doing it for the features, not the cost.

We made the two-door prototype first, but what we’re going to do for production is make just the four-door, so that’s the one we’re concentrating on now. It incorporates the bigger battery pack. We think that if we put it out there, 85% to 90% of customers would order the four-door, so we made the decision to make the four-door first and get it out there. Then we’ll come back with the two-door, then, hopefully, the right-hand drive version of those two, and then other models after that.

Charged: Do you think the next models will be drastically different platforms, or will they be derivations of what you’re building now?

Robert Bollinger: I’d like to base it off the same chassis layout and the same structure. What is our DNA? We have to be different. Things like the pass-through and the Class 3 strength are part of our DNA now. So we can make more vehicles off of that same DNA. If we ever worry about pennies, and bring down the cost, and take out that kind of stuff, then we’re so similar to other stuff that’s going to be out there, it’s not really worth it. We should really just stay as different as possible.

Charged: What do you think is a best-case scenario for first deliveries?

Robert Bollinger: Early 2020. We’re going to start production in fourth quarter 2019. Our idea is to have a fully engineered, optimized four-door CAD model this year, as we line up our vendors, of course. And then, tooling, ordering, all in the first half of next year. And it all starts to come together in the second half of 2019, then we send them out in early 2020.

Charged: What do you think is the biggest challenge to meet that deadline?

Robert Bollinger: It’s an aggressive timeline. Because when we debuted our vehicle last July, that was a fully working prototype, and we figured out an awful lot of stuff. But there’s so much to do from that point, and we’ve been on it like crazy since then. I think the biggest challenge would be finalizing our vendors. We’ve had a lot of great vendor support from the beginning, but it’s really just lining them up and learning that whole sequence. I’ve hired a number of people who have a lot of experience with that, to help me, so we’ll get there. But that’s the thing that’s scariest to me.

Charged: What can you tell us about your team?

Robert Bollinger: Well, I always want to talk about my engineering team: Chief Engineer Karl Hacken, Powertrain Engineer CJ Winegar, HV Engineer John Hutchison, and LV Engineer Dan Aliberti. It’s incredible what I’ve learned from them, and how they’ve been able to just jump on this, and bring what they know. And then what they don’t know, they go and figure it out and find the right guys. It’s really all about the team.

We’ll probably hire about 10 more people this year. And then as we ramp up for production, we’re going to be having vendors make major parts for us. The chassis, the body and lights and stuff like that, will come from vendors in the Detroit area who have done that for OEMs for decades. So they’ll make our bodies for us, and major components will come in and we’ll assemble it ourselves. So that whole assembly line, that’ll be 50 to 70 people there. But that’ll be towards the end of next year.

Charged: You hired Optimal to help you with the final bit of engineering and reliability studies, and then you plan to build your own plant?

Robert Bollinger: We want to assemble it ourselves now, because we’re lower-volume than we were originally planning. Our first thought was that we would go for higher volume and third-party manufacturing. But I want us to do this ourselves, be right there, hands on, with the final quality and the final craftsmanship. So we’re going to assemble them ourselves.

This article originally appeared in Charged Issue 37 – May/June 2018 – Subscribe now.