Every Tesla model has arguably been a historic vehicle. The Roadster was the first EV to offer the performance and aesthetics that attract car buyers. Model S was the first mass-produced EV to deliver this combination, and Model X delivered it as an SUV. Model 3, the culmination of the company’s master plan, was the first to bring this winning formula to the mid-priced segment. With the new Model Y, Tesla has refined all the features of Model 3 in a form factor aimed squarely at the most popular market segment in the world.

This revolutionary new EV arrived on the market with unfortunate timing. Tesla was just beginning customer deliveries when the COVID-19 pandemic forced the company to more or less shut down operations for weeks. When we started work on this article, the best estimates were that only a couple thousand people, all in the US, had received their Model Ys. We were able to interview two of the fortunate few, both of them long-time Tesla observers in very different fields, one on the drivers’ side and one a manufacturing expert.

Driving Model Y

Roger Pressman probably knows as much about Tesla vehicles, at least from the consumer standpoint, as anyone in the world. Roger is the founder of EVannex, a manufacturer and distributor of aftermarket accessories for Teslas. He has owned all four of Tesla’s mass-market models (you might say he’s a S3XY guy) and in the course of developing products for them, has minutely measured and examined each one. At the time we spoke, Roger had been driving his Y for about a month, and he shared his first impressions with us.

“The key word for the whole car is refined,” Roger told Charged. “I’ve driven all four cars, as a daily driver or a family car for long trips. Obviously, the S and X have more luxury features and a more luxury feel. They’re bigger cars, and they have some bells and whistles that the Y doesn’t have. However, pretty much all the other characteristics of the car represent a refinement of the entire Tesla line, and that’s a really good thing. I think Tesla’s learned a lot over the last eight years, and the Y is a culmination of that.”

Twin vehicles

Tesla has said all along that Model Y would be based on Model 3. In January 2019, Elon Musk said that the two would share 76% of the same components, which would allow Tesla to leverage economies of scale and greater efficiency, not only in its supply chain, but also in terms of the supply of parts to its service centers. (Tesla had a similar goal for Model X, but the list of new features for the SUV ballooned, and it ended up sharing only about 30% of its parts with Model S.)

The first question we asked Roger was how Models 3 and Y differ. “With regard to functionality per se, there isn’t a whole lot of difference between Y and 3,” he told us. “But I could think of lots of little things that are really cool. You have the hatchback on the Y, which is automatic, pops up nice and smoothly and slowly. You don’t have that on Model 3—in order to achieve it you have to buy an aftermarket product.”

One noticeable change is that the front and rear tires are different sizes. The rears are 275 mm wide, and the fronts are 255 (most observers expect this to be the case only for the Performance model, but that remains to be confirmed). Some may complain that this arrangement prevents you from rotating the tires, but it has advantages, as Roger explains.

“It gives the car a very aggressive look, and visually gives you the feel of a wider car than it really is. When you look at it from the rear particularly, it has a feel of a wide stance. Wider tires and a slightly wider feel to the car gives you better cornering capability, better traction on the road. Handling of this car for an SUV is remarkable.

“Having driven Model 3 for two years, I do think it’s probably a little better driver’s car—just a little, not a lot. It’s lower, has a lower stance. You just have a little bit better feel for the road. But Model Y is amazing for an SUV or crossover. That’s a perception thing, but a Model 3 Performance really is a driver’s car—doesn’t lean, brakes well, holds the road, doesn’t feel particularly light at high speed. A Model Y has those characteristics, but you could tick it down just a little bit because it’s an SUV.”

When it comes to the interior, and the vehicle functions, Models 3 and Y are pretty much the same except for one key attribute. Long-time Charged readers may be tired of hearing me harp on interior storage space, but this is very important for some buyers, and it has always been a sore spot with EVs. Actually, not with Teslas—in fact, one of the brand’s selling points has always been how much they can haul, thanks to their skateboard battery configuration. Model 3 doesn’t have much storage space (15.0 cubic feet), and nobody ever claimed it did—Model Y, however, is quite a different animal.

“One thing that’s shocking on the car is its interior volume,” Roger told me. “It really can hold a lot of stuff—that’s another pleasant surprise when you get the car.” I was very surprised to learn that Model Y actually has more space with the seats folded down (68.0 cubic feet) than the famously roomy Model S (60.2), and not that much less than the massive Model X (87.8). Roger has X and a Y sitting next to each other in his garage. “The Y isn’t much smaller when you’re standing at the hatch gate and looking in.”

As musicians, sports enthusiasts and other lovers of material goods know, storage isn’t just about cubic feet—it’s also about the design and how easy it is to load stuff in and out. Model Y has very little liftover in the back, making it easy to load heavy objects, and the seats fold almost flat, making it easy to slide ‘em in. “It’s close to a flat floor,” says Roger. “When you fold down the second-row seats, there’s a slight angle—they don’t go dead flat, but very few cars do, actually. There’s a button in the back which allows you to lower the seat backs of the second row so you can throw some stuff in quickly without having to walk around the car and open the door. The other thing that’s nice is that the center portion of the second row folds down without the other two sides folding down. So, if you have something long and narrow, like a piece of lumber, you just fold that down, shove it in the car, and you’re good to go.”

Will Model Y take off, or take over?

Roger kept coming back to the word refinement. “I really do think from an industry point of view as well as a product line point of view, Model Y represents a refinement of all the ideas that have been integrated into Tesla’s other vehicles, and I believe that’s a very good sign for the company. I think ultimately Model Y is going to be the biggest-selling car in the line.

“It is remarkably better looking in person than it is in either video or in photos. It’s really shocking. The car looks like a small typical SUV with a Tesla feel in photos and in video.

“With regard to performance, it’s cool. I have a Performance Y, so when you come up to a stoplight, pretty much no matter who’s next to you, they’re not going to stay with you. I mean, 3.5 seconds from 0 to 60 is really fast. Most drivers on the road now recognize, you don’t mess with a Tesla, and the Model Y exemplifies that. It may look like just a small SUV, but it ain’t. It’s a performance car and it acts like it.”

The start of Model Y deliveries should have been the automotive story of the year, a gathering wave of rave user videos and media reviews. The coronavirus crisis brought it all to a screeching halt, and by the time the pandemic passes, the launch will be old news. Tesla was robbed of its big media splash—will that hurt Model Y sales? “I don’t think it’s going to make a bit of difference,” says Roger. “I think once things open up again, this car is going to take off, once people see it on the street.”

As you may recall, the market launch of Model 3 coincided with a round of eulogies for the sedan. SUVs were (and still are) dominating the market to such an extent that the Big Three basically stopped producing sedans in the US altogether. Some said Tesla had missed its moment, coming out with a sedan just as sedans were officially pronounced dead. Sales figures have proven that prediction wrong—Model 3 quickly became the best-selling EV in history, and is handily outselling all competitors in the luxury sedan segment. It’s only logical to expect Model Y to be even more popular.

“I think Y dovetails into the current trend perfectly,” says Roger. “It provides all the benefits of Model 3, and it’s also an SUV, which gives you a level of practicality that no sedan can achieve. So, it’s the full boat, and that’s why I believe it will ultimately become the most popular car in the Tesla line.”

Manufacturing Model Y

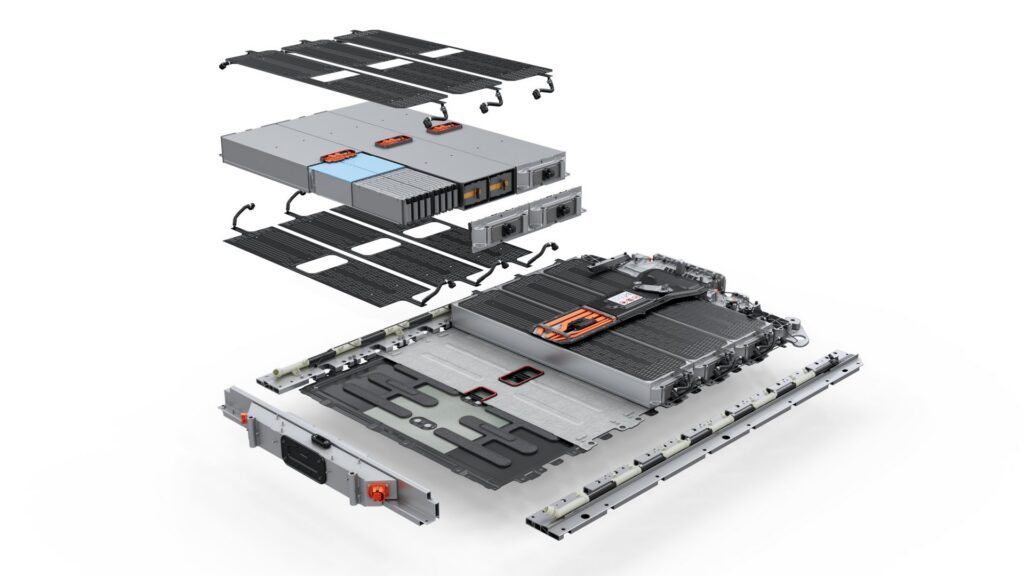

Drivers may not notice much difference between Models 3 and Y, but the new Tesla has many innovations under the hood, a couple of which are extremely important: the heat pump combined with the Octovalve, and the rear underbody castings.

Things are heating up

Model Y’s new thermal management system, the Octovalve (which sports a picture of an octopus with a snowflake) is the heart of the car’s cooling and heating system, and replaces the Superbottle used in Model 3. All previous Tesla models used resistive heating systems, whereas Model Y uses a far more efficient heat pump.

“The heat pump means that the car is able to operate more efficiently,” Elon Musk recently told the Third Row Podcast. “So, even though it’s heavier and has a bigger cross-sectional area, it’s actually able to achieve a range that is about the same as the Model 3. Normally you’d expect something that is around 10% heavier, [with] around 10% bigger cross-sectional area, to have 10% less range approximately. But we were able to make the car a little better than 10% more efficient.”

Elon concedes that there’s no easy way to describe a heat pump. It’s “kind of like an air-conditioner backwards.” Tesla’s heat pump includes several clever features, including a local heating loop, which is designed to improve performance in low-temperature operation. “Heat pumps typically encounter issues around minus 10 to minus 20° C,” says Elon. “They have a problem spooling up. So, the solution that the Tesla HVAC team came up with was to have a local heating loop. The thing will basically spin itself up and get hot locally before opening another valve, that then tries to heat the cabin.”

Casting call

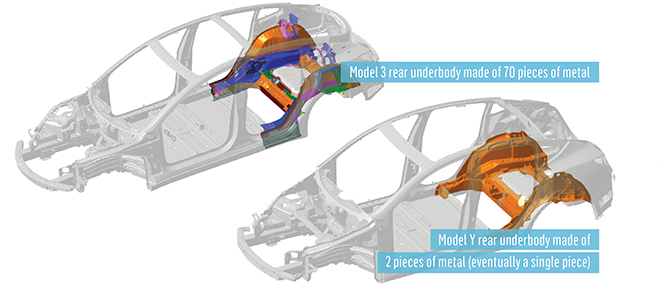

Another innovation is hidden away in the rear underbody of Model Y, where Tesla has replaced about 70 parts with two enormous aluminum castings.

Manufacturing engineering expert Sandy Munro once described Model 3’s chassis as looking like “a patchwork quilt,” an assessment that Musk seems to agree with. It’s functional and achieves a high level of safety, but “the complexity in the body shop is insane. I think our Fremont body shop feels like a Dickensian nightmare. It’s sort of cool in a steampunk way, but not something you want to repeat. So, the current version of the Model Y has two big high-pressure die-cast aluminum castings that are joined, and then there’s still a bunch of other bits that are attached.”

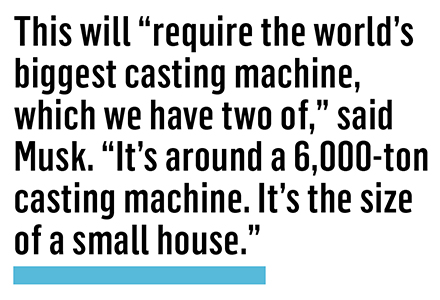

Later this year, Tesla will transition to using a single-piece casting for the rear underbody, which will also integrate the rear crash rails. This will require “the world’s biggest casting machine, which we have two of,” said Musk. “It’s around a 6,000-ton casting machine. It’s the size of a small house.”

According to Musk, this innovation allows the size of the body shop to be reduced by about 30%, and greatly reduces the number of robots required. That’s an improvement that Tesla could eventually bring to Model 3 as well, but given all the other things the company has on its plate, such a retrofit will probably have to wait another two years or so, said Musk.

Elon told Third Row that Model Y’s huge casting was inspired by a die-cast toy car on his desk. “I’m looking at the little model cars that you have on your desk, and they cast those things, and I’m like, ‘Well, geez, what’s the actual limitation on casting? Where do we hit the limit of physics?’ And it’s like, ‘Oh well, actually we don’t.’ Okay, great. What would it take to cast the whole damn car? And they’re like, ‘The whole damn car? Because that would be like a 15,000-ton press and that’s just way too terrifying.’ So, what if we cast a third of the car? Okay, that sounds maybe not totally crazy.”

Tesla’s casting process is a little more complex than that used at the Hot Wheels factory. “We’ve got all these things that predict the flow pattern and solidification and everything. High-pressure aluminum back casting, it’s pretty wild. I mean that aluminum is getting shoved into the die in about 40 milliseconds. It’s insane, yeah. Because you’ve got molten aluminum and it’s got to flow through that mold so frigging fast. You draw a vacuum on the mold so there’s not even any air in there, and you just hit it with a massive frigging piston and blast that molten aluminum in there, and then you got to cool it in just the right way so that you have good strength.”

Tesla is using a special aluminum alloy that requires no heat treatment after casting. “For the Model S and X we have castings on the corner nodes—the main load-bearing portions of the car are high-pressure die-cast aluminum,” Musk explained to Third Row. “They’re quite complex. But the thing that really drives me crazy about those is that they require a heat treat afterwards. So, when you heat-treat it, then you get warping and then it’s a big pain in the butt [and] the bigger the part is and the more complex the shape is, the more warping you’re going to get. So, it’s very important in doing this that we developed an alloy…that is sufficiently strong and has good elongation. Especially important for elongation in a crash event, without requiring a damn heat treat and turning the thing into a pretzel.”

Sandy Munro tears things down

Sandy Munro has been in the auto manufacturing game for decades, and has performed teardowns on every mass-produced Tesla model. He probably knows more than anyone outside the company about how these vehicles are built. When Charged spoke with Sandy, he was in the middle of tearing down a Model Y, and he agrees that the most significant design improvements are the heat pump, the Octovalve and the rear castings.

Tesla is not the first automaker to employ large-scale castings. “Cadillac had one,” says Sandy. “BMW has had them.” Be that as it may, the reduction in the number of parts is quite significant. Sandy estimates that the rear underbody of Model 3 had around 80 parts, and another 80 fasteners. “They used every type of fastener you could use on aluminum. The new one has two major parts, it’s got two brackets that they use for joining them, and then they’ve got two bolts in each one. We’re going from maybe 150 parts and fasteners, down to 4 parts and 8 bolts or whatever. They took into account where they put the springs, where they put the wire harness connections, the brake lines, all kinds of stuff is built right in. It makes it super-easy for the [assembly line] operators to put things together.”

Sandy told us that one of the most intriguing questions about the massive casting is what alloy Tesla is using—his ears perked up when he heard Musk describe using an aluminum that doesn’t need a heat treatment. He immediately sent off a sample of the casting material for a spectrographic analysis. “You take a chunk, and give it to one of these guys that has very sophisticated equipment,” Sandy told Charged. “They blow it up basically, and then they check for the…different colors to tell you what the different alloys are.” The analysis will reveal exactly what the material is made up of. These are the kinds of details Munro’s customers will happily pay for when his firm starts selling its reports on the Model Y teardown.

Sandy’s eagle eye spotted several details of the underbody casting that hint at features Tesla may add down the line. One is an air shock system (available as an optional feature on Model S, and promised for Cybertruck), which could lower the body to get better mileage at highway speeds, and possibly even allow the vehicle to “kneel” to make it easier for elderly and/or disabled people to get in and out. Another possible future feature is a third row of seats. Sandy is almost certain that these will be rear-facing. “When I look at the casting, there’s four mounting points that are not being used right now, but they would be ideal for popping seats in.”

Body building

There are numerous other improvements under the hood. “The body build is 1,000% better,” says Sandy, who famously made some scathing comments about Model 3’s body construction. “There are still issues, but they’re minor in comparison to what I have seen in the past.”

Another techie detail Sandy loves is the wiring. “I like the wire harness arrangement—they’ve done a bang-up job at [making] it easier for people to put things together. Outside of the vehicle, where the wires are passed around outside, they used corrugated sheathing.” This protects the wire from rodents. “Inside, they used plastic injected molded casings. You take the wire bundle and you snap it into that, and it guides it. It’s much, much easier for the operators to pull a wire harness in and snap it into position.”

The wire

Early in the production of Model 3, Tesla admittedly tried to automate a little too much—one of the problems was that the robots had a hard time putting wiring harnesses in place during assembly. Based on some patents Tesla had filed, and rumors that were floating around, Sandy was hoping to see some major innovation in terms of low-voltage wiring.

“[Elon] said he was going to go from about 1.6 kilometers down to about 0.8 kilometers. I was very interested in seeing that, but that didn’t show up. I thought they were going to go to multiplexing—in essence, what that is, is there’s a module inside the door panel, and it has one wire going to it, and it’s the power wire. The rest of the signals are Bluetooth or something like that inside the car. If I would have seen that, I would have been really impressed. Now, the reason no one else is doing anything like that is because it is very expensive, so I think maybe they looked at it and said, ‘Maybe next time.’ But the bundles are tight, the wires are on the light side from a gauging standpoint. They’re signal wires mostly—very few power wires.”

Real-time refinements

Auto engineer Richard Amacher was another fortunate soul who got his Model Y early, and he made a detailed video about it for CleanTechnica. His only major complaint was that he found the HVAC system to be very noisy. Roger Pressman had the same critique: “Yes, it is noisy. Particularly at high fan speeds above, say, seven, it’s a very noisy system. What I try to do is to pre-cool the car before I get in it. Then once I get in the car, I crank the fan down to a four or five, which is completely livable. But if you have the fan up in the neighborhood of eight or nine, it’s noisy.”

The rackety AC did not get past Sandy Munro—he heard about the complaints and investigated. In one of his videos, he shows us that Model Y’s compressor is cleverly isolation-mounted to prevent it from transmitting noise and vibration to the rest of the vehicle, but that it lacks a noise-deadening plastic case that Model 3’s AC compressor has. It didn’t take long for Munro to receive a call from someone at Tesla, who told him that a “running change” is underway to add a similar insulative case to Model Y’s heat pump.

This brings us back to the term refinement. One of the things that makes Tesla unique among automakers is its openness to criticism and quick response to feedback. Remember how the company promptly made improvements to Model 3’s braking performance via an over-the-air software update, after a complaint from Consumer Reports? As other automakers do, Tesla updates and improves its vehicles, as well as the production equipment and processes used to build them, every time it brings a new model into production. However, it takes this ethos of constant incremental improvement a step further and, in Silicon Valley style, makes running changes in real time. The eventual result is an awesome product.

This article appeared in Charged Issue 49 – May/June 2020 – Subscribe now.