One major challenge that the EV industry has had to overcome is figuring out how to test its new products. No matter how great and innovative you think your new design is, if you can’t adequately test it, how do you know it’s truly great?

Until recently, there were no standard operating procedures for testing vehicles with massive lithium-ion battery packs onboard. The industry quickly learned that there is a lot that can go wrong in a new design that has to last for hundreds of thousands of miles through extreme temperature swings. To make matters more complicated, these new EVs also interact with the outside world in a much more complex way – plugging in to the grid through hardware from dozens of different manufacturers.

Over the past decade, EV engineers began to work hand-in-hand with test and measurement companies to design the right testing products. “A lot of customers that come up with new technologies put the burden on us to develop the right features in our test equipment,” Luis Veliz, Chroma Systems Solution’s Director of Automated Test Equipment (ATE) told Charged.

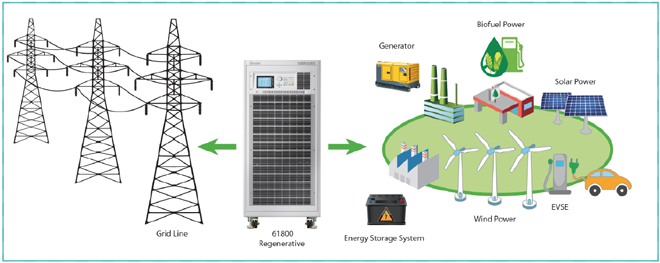

Chroma is an electronic instruments company that is uniquely positioned to capitalize on the growth in vehicle electrification. The company offers testing products in all four quadrants – AC input, DC input, AC output and DC output – which has allowed it to enter the EV market at many points throughout the electrified systems – from charging station simulation to BMS testing and everything in between.

“We’re all across the supply chain, because everything has to be tested, from a small resistor all the way up to a final product,” said Veliz. “Our customers include both the automakers and their suppliers. Not all EV companies design all their own systems, but when they integrate third-party parts, those have to be tested during development and final production.”

Evolving with EVs

Chroma’s suite of products includes systems for testing how EVSE interacts both with the grid and with vehicles. One feature that Chroma developed while working closely with customers is a constant impedance mode for AC and DC electronic loads. “Most electronic loads have constant current, resistance, power and voltage modes,” explained Veliz. “We introduced constant impedance (CZ) mode to better represent real life. If you’re measuring the AC signal at the wall, for example, and someone starts running a vacuum cleaner somewhere, that’s going to induce a certain inductance into your testing. So we’re simulating that in different products so you can test based on different activities that are going on in the real world.”

Chroma’s regenerative grid simulator model 61800 series

Chroma’s regenerative grid simulator model 61800 series

“Consumer electronics chargers are a good example of where you would use a DC load and CZ mode,” continued Veliz. “Let’s say you have a Mini-USB charger where you can plug in smart phones from multiple manufacturers (Samsung, HTC, Google, etc). Now we can simulate each phone’s impedance to make sure the charger performs the way it is supposed to every time.”

Another clever feature that Chroma introduced for DC loads is the ability to accurately simulate large and small currents using the same hardware. “On most DC electronic loads, when you start drawing a smaller current, they are not as accurate,” said Veliz. “They’re typically designed with a 10% and 100% load range. We introduced a third range at 1%. Let’s say you want to test a battery that normally draws 60 A for its main application, but from that battery you’re also drawing 200 milliamps for some components. For example, if you want to turn on an LED, that’s a really small current, but you want to simulate that at some point. So now with one product you can accurately simulate the big stuff and the little stuff to know for certain how it will behave in the real world.”

As more and more drivetrains are being powered by electricity, along with the vehicle’s accessories, Chroma has the ability to become a one-stop testing shop for automakers. And with its advanced test systems for the LED and solar PV industries, Chroma can even simulate more exotic vehicle accessories like advanced lighting systems and solar integrated roofs.

“We’ve noticed a trend that automobile manufactures who are entering the EV market are also looking into solar applications – high-power inverters, possibly to leverage the battery technologies they are developing for their cars,” added Steve Grodt, Chroma’s Director of Business Development. “They look to Chroma’s 61800 Regenerative Grid Simulators and 62000H Solar Array Simulators to create a micro-grid environment. To tap into another segment, automakers use the inverters and batteries to deliver energy storage systems for military applications.”

Battery team

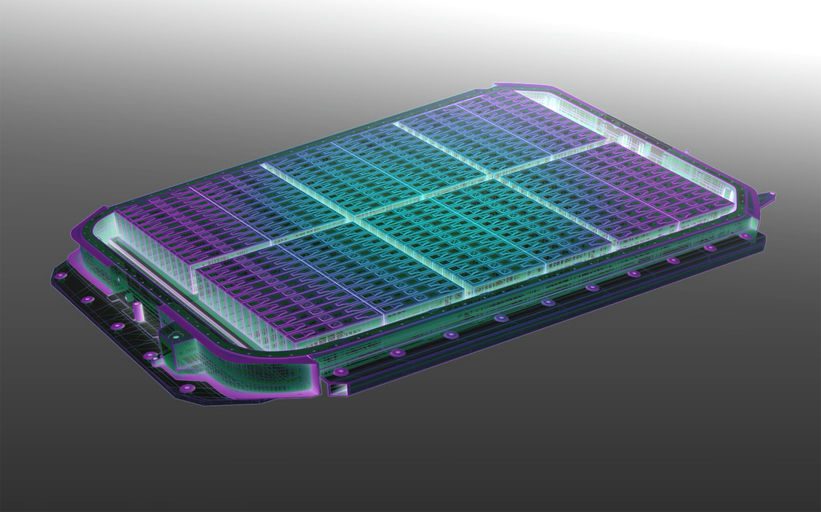

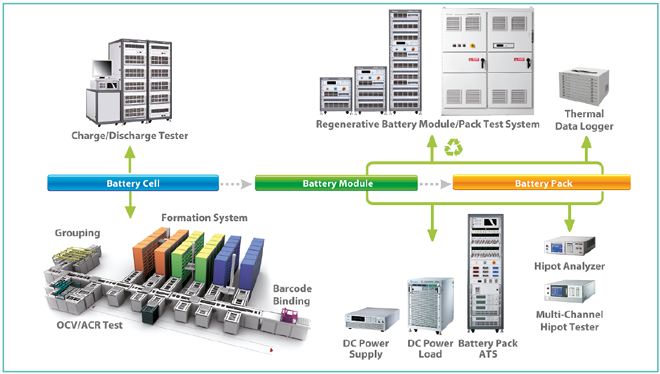

Chroma has a specific team that’s dedicated to all aspects of battery testing – cells, modules, packs, BMS, etc. The company’s systems have power ranges from 100 W up to 1 MW, and from 60 V up to 1,500 V. The equipment is used in all aspects of prototyping, design verification, and end-of-line production tests.

One example of design verification performed with Chroma’s equipment is testing the balancing functions of a battery pack’s BMS. For active balancers, designed to shuttle energy between cells, engineers will use a DC load to draw current from one cell and see how the BMS reacts. “The purpose of the BMS is to make sure all the cells are within the same voltage range, and you need to confirm that it always works,” said Veliz. “You also want to make sure that it maintains control of any bad cells, and it doesn’t continue to draw current from them.”

Chroma’s battery test and automation solutions

Chroma’s battery test and automation solutions

A typical end-of-line production test will include charging and discharging a pack in about two-minute intervals, and measuring to ensure that it’s within certain parameters. “In that case we’re usually looking for DC-IR, which is the internal resistance of the battery,” said Veliz. “When you go from drawing 10 A to 2 A, the voltage will change. Using the rate of change of the voltage and Ohm’s law, you calculate the internal resistance of the battery. If the DC-IR is outside of the design parameters, there could be a problem with anything from a single faulty cell to a physical connection. Then there are also usually tests to ensure that the pack can charge and discharge at its design limits: 1C, 2C, etc.”

Designed for automation

Chroma says what really sets it apart from the competition is that it has focused on testing automation since the inception of the company. “Our software makes us unique,” said Veliz. “Usually, you need to be a programmer to work with a software package. In our case, as long as you know what parameters you want to test on your product, you can script a test on our software without ever knowing how to program in C, BASIC, or any other language. Creating the scripting without manual programming can save engineers a lot of time.”

The company stresses the importance of using high-quality components to build its equipment for automation and production environments. In the high-speed and time-critical world of computer and automotive manufacturing, a few seconds of downtime can cost tens of thousands of dollars. Chroma ships its products all around the world, including to manufacturing environments that are less than ideal, with dusty atmospheres and irregular grid power. “With reliability and speed-of-test in mind, we design products a little differently, with higher-quality components, so you know it’s going to work in any high-volume manufacturing environment,” said Veliz.

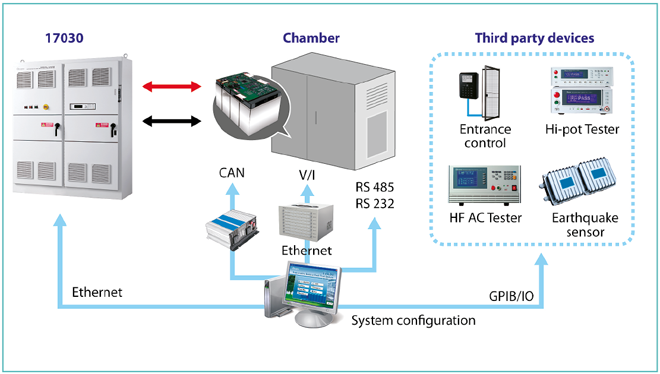

Chroma’s software platform – Battery Pro (for Model 17030/17020/17011)

Chroma’s software platform – Battery Pro (for Model 17030/17020/17011)

Pushing the boundaries

There are a few features in the test and measurement world that are considered the frontier of the industry, including accuracy of the settings and the measurements, higher power density, and speed of tests and communications.

To maintain its position among the top of the pack, Chroma spends a considerable amount of resources on R&D. The company says it has about 540 R&D test engineers that do nothing but develop new products and features. In addition to having a large and diverse group of engineers, every year Chroma makes a big investment – as much as 15% of its revenue – back into R&D to develop new technology and products to ensure precision, reliability, and uniqueness.

According to Veliz, it’s paying off. “I can think of at least five features that we’ve introduced into the market in the last three years that were so useful to customers that other companies followed our lead and added them as well.”

This article originally appeared in Charged Issue 28 – November/December 2016. – Subscribe now.