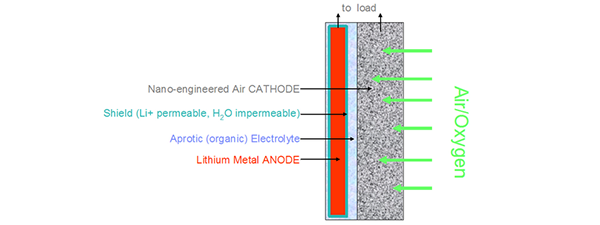

IBM announced Friday that Asahi Kasei and Central Glass will join its Battery 500 Project team to collaborate on research into lithium-air batteries. The two companies have some very pertinent expertise, due to their existing work with lithium-ion batteries – Chemical manufacturer Asahi Kasei makes separator membrane, and Central Glass supplies electrolytes.

The biggest challenge in the EV world today is not range anxiety, charging standards or right-wing talk show hosts. It’s energy density. IBM’s researchers, among other commentators, have opined that, for EVs to become competitive in the marketplace, the energy density of batteries needs to increase by a factor of 10. Lithium-air batteries have the potential to make that happen, due to their lighter cathodes and the fact that their primary “fuel” is the oxygen readily available in the atmosphere. Scientists at IBM Research-Almaden started the Battery 500 Project in 2009 to develop a lithium-air battery that could take an EV 500 miles on a single charge.

“These new partners share our vision of electric cars being critical components of building a cleaner, better world, which is far less dependent on oil,” said IBM’s Dr. Winfried Wilcke, who initiated the Battery 500 Project. “Their compatible experience, knowledge and commitment to bold innovation in electric vehicle battery technology can help us transfer this research from the lab onto the road.”

“New materials development is vitally important to ensuring the viability of lithium-air battery technology,” said Central Glass Director Tatsuya Mori. “As a long-standing partner of IBM and leader in developing high-performance electrolytes for batteries, we’re excited to share each other’s chemical and scientific expertise in a field as exciting as electric vehicles.”

“We are very focused on addressing environmental challenges and limitations with diverse technology to build a brighter future,” said Asahi Kasei’s Tetsuro Ohta. “This alliance allows us to explore a new path to developing an improved rechargeable battery performance that cannot be met with conventional technologies.”

Image: IBM