UK-based Altilium is building a new EV battery recycling plant in Plymouth, as the company embarks on the next phase of its ambitious growth plans.

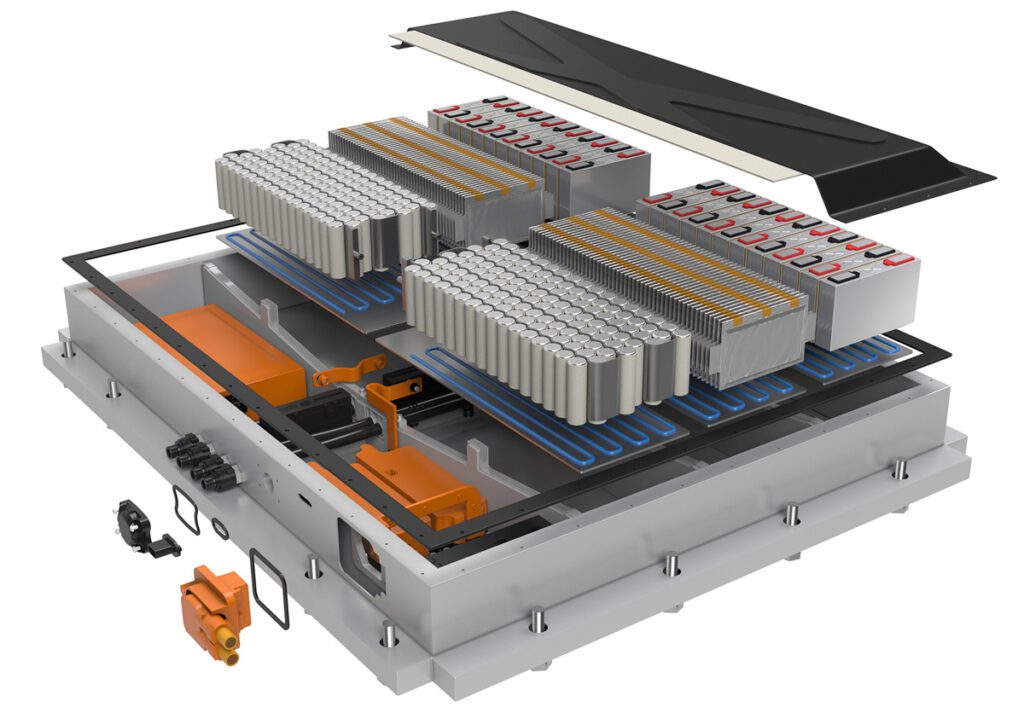

The 18,000-square-foot facility will use Altilium’s proprietary EcoCathode technology to recycle old lithium-ion batteries from EVs and recover the critical metals needed to power new EV batteries. Located in Plymouth’s Estover Industrial Estate, the new recycling plant is expected to begin operations by the end of the year.

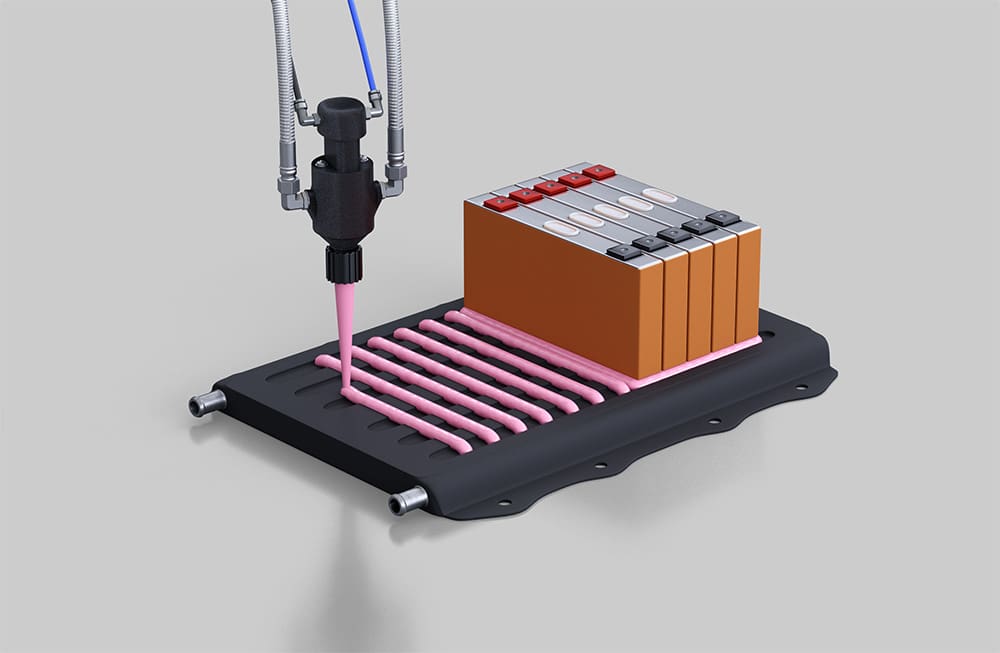

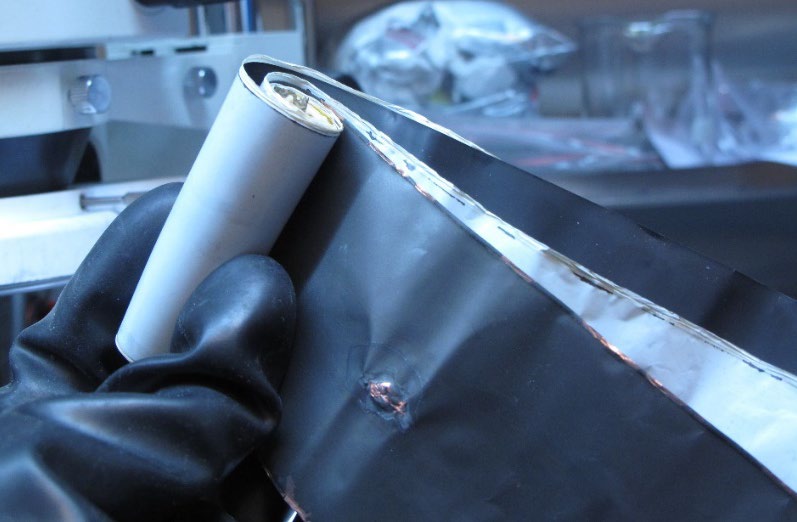

The company’s proprietary EcoCathode recycling process converts end-of-life EV batteries and manufacturing scrap into battery precursors, cathode active materials (CAM) and cathode precursor (pCAM) for direct reuse in new batteries.

The new plant will have the capacity to process scrap from over 150,000 EVs per year, producing 30,000 MT of CAM.

Altilium says its EcoCathode process has been independently validated by the University of Plymouth and proven in a scaled-up pilot operation, recovering over 95% of cathode metals from waste EV batteries, in a format that can be directly reused in battery manufacturing.

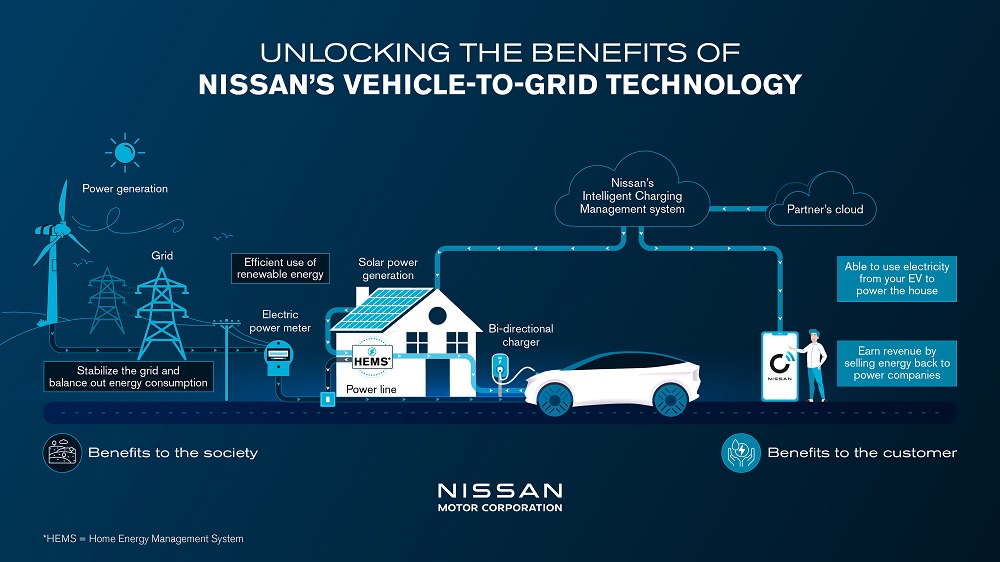

The company is working with OEMs including JLR and Nissan to develop a circular economy for battery materials in the UK.

The Southwest of England is emerging as a battery hotspot—lithium mining is taking place in Cornwall and a major gigafactory is being built in Somerset.

Source: Altilium