COFICAB, worldwide leader in the design, manufacture and sales of innovative wires and cables for the automotive industry, presents e-COF POWER+. This newly developed cable is part of the e-COF family brand (high voltage cables), specially designed to fulfill international standards for BEVs and PHEVs vehicles.

e-COF POWER+ uses two different insulation materials, taking advantage of each insulation type assuring high level of flexibility, mechanical and chemical protection for the jacket and getting a better thermal performance compared to a standard T4 (150°C/3000h) solution.

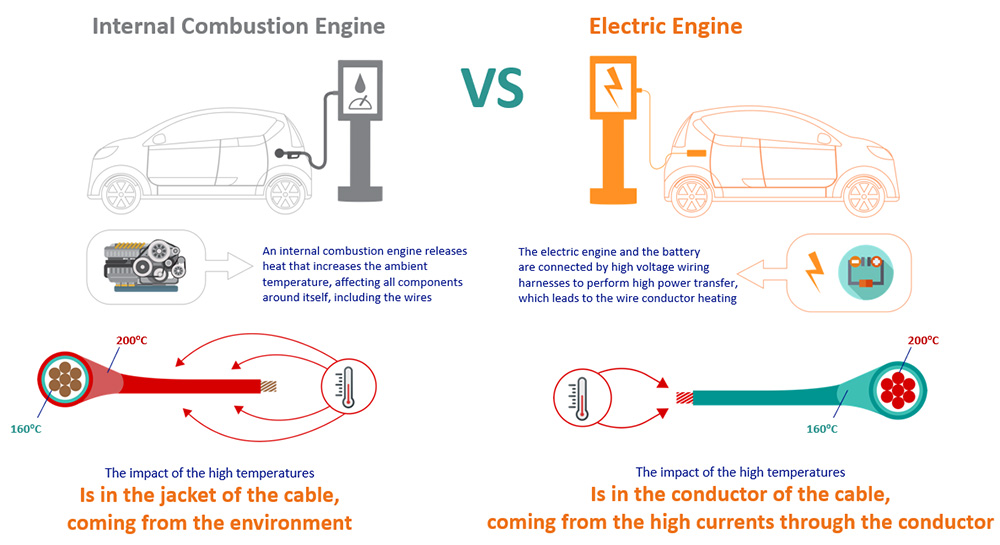

In electric vehicles, unlike internal combustion engines, the cables’ heat source comes from the high currents that pass through the conductor. In fact, in electric vehicles, quick speed changes will lead to a fast-current increase in the conductor and connectors, and consequently to peaks of temperature on the system.

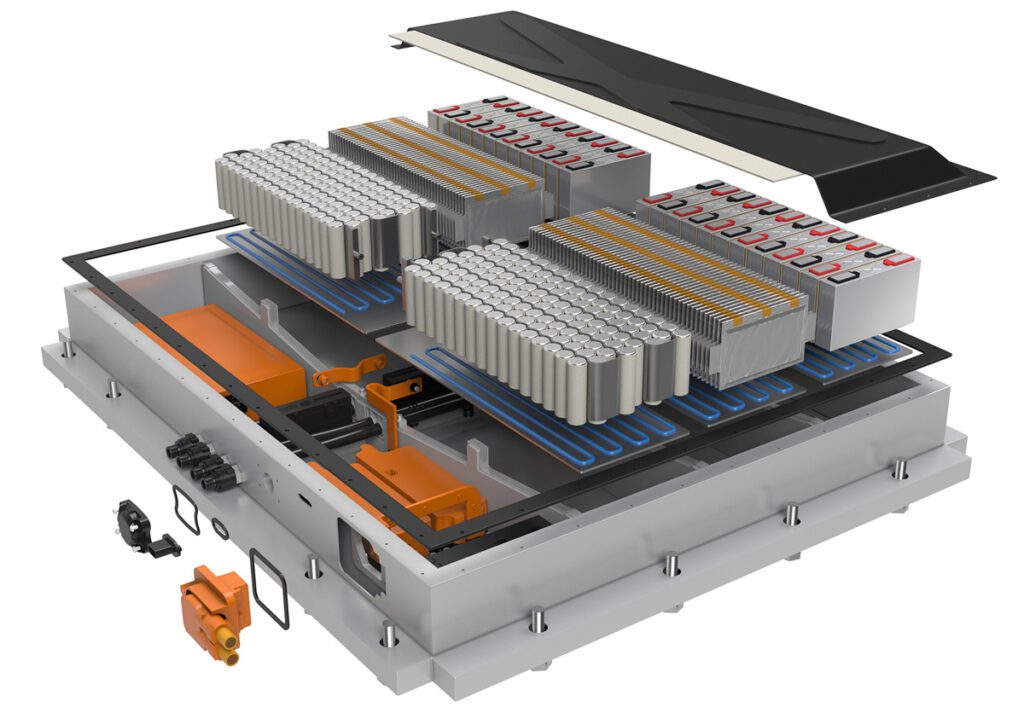

On this new Electrical Vehicle technology, the behavior of the cables needs to be understood. For this purpose, several cable constructions and designs, using different insulation materials, were studied.

In order to understand the behavior of the conductor and the insulation materials, thermal studies need to be performed. In addition, the bending force must be studied in order to analyze the cables’ flexibility.

The optimal solution for a cable design would be:

- For the inner insulation:

1.1 High performance on temperature and good insulation volume resistivity

1.2 High level of flexibility

- For the outer jacket:

2.1 Mechanical performance

2.2 Chemical resistance

2.3 High level of flexibility

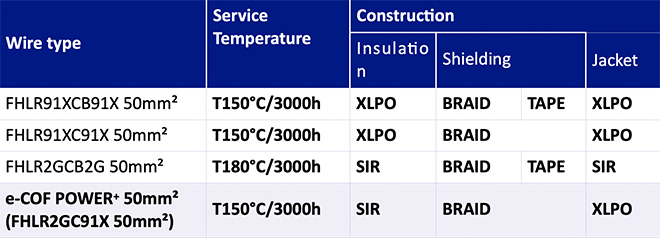

Several studies were carried out using different cable constructions, designs and insulation materials to understand the different behaviors of each cable type in Electrical Vehicle technology:

Table 1 – Cable constructions, designs and insulation materials

In the Thermal Study – Overheating by current overload – a Short Circuit Test was carried out by applying an electric current of 500A for 30 minutes and the temperature of the conductor and the jacket are measured.

The current of 500A was selected to reach an inside temperature of around 200°C.

In the Thermal Study – Overheating by current overload – During the Bending Force Test the cable’s flexibility is measured and quantified. Throughout this test, the cable’s bending force in its new state was measured as well as after 30 minutes of applying 500A to the wires.

The Thermal Study – Overheating after thermal ageing test (240 hours) – Bending force Test was the last test carried out. This test measures and quantifies cable flexibility. During this test the cable’s bending force was measured, first, in its new state and, second, after thermal ageing test at 175°C during 240 hours.

In conclusion, different cable designs were tested with currents of 500A for 30 minutes. The applied electric currents increase the conductor and inner insulation’s temperature close to 200°C and around 150ºC on the outer insulation jacket.

e-COF POWER+is the most suitable design for these conditions, as it combines and takes advantage of the strong features in both materials. An inner insulation of silicone rubber is more suitable for temperature of 200ºC and the outer jacket insulation of XLPO for 150ºC.

Normally, all cable designs after being overheated with applied electric currents of 500A for 30 minutes, or after ageing test at 175°C during 240 hours, lose some flexibility and become brittle, with the exception of e-COF POWER+ Innovative proposal that maintains the initial mechanical properties.

In summary, the e-COF POWER+ provides the following benefits:

- Outstanding performance due to Silicone Rubber in inner insulation;

- Good mechanical and chemical protection for the jacket due to XLPO insulation;

- High-level of flexibility similar to Silicone/Silicone wires;

- Increase of current capacity for equivalent existing market solutions.

- Cost reduction

This innovative product is available in copper and aluminum conductor, in single and multicore solution.