Through the delivery of our composite and metallic bipolar plates, Dana is increasing the viability of fuel-cell-powered vehicles and supporting a more eco-friendly charging infrastructure — ultimately fulfilling our vision of helping our customers achieve their sustainability objectives throughout the entire power supply chain.

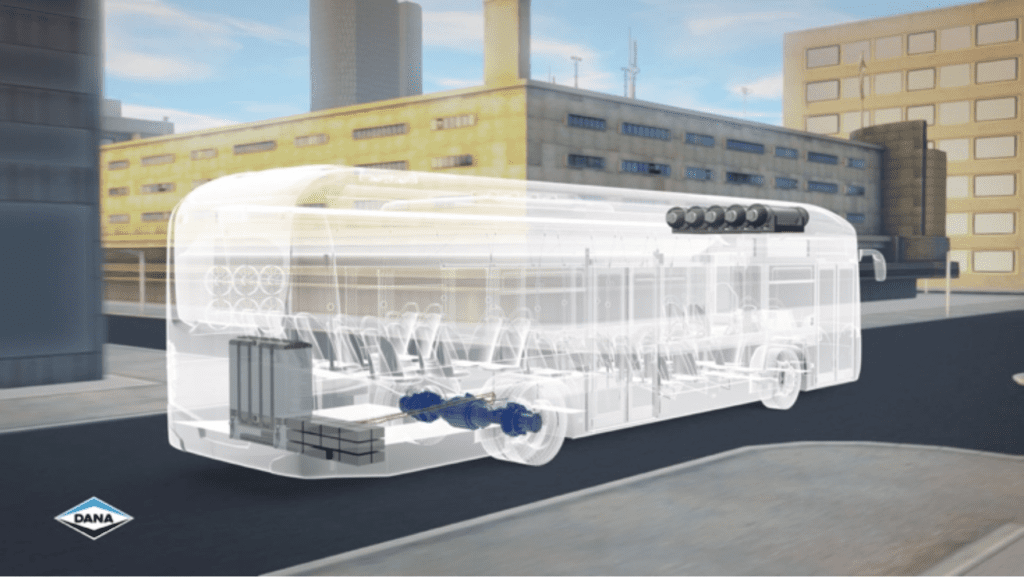

As OEMs across the globe continue to increase their investment in and production of electrified vehicles, the mobility industry is undoubtedly headed towards a cleaner, greener future. In the quest to shift away from fossil fuels and adopt cleaner power sources, hydrogen fuel cells are emerging as an advantageous alternative to both hybrids and battery-electric vehicles. Fuel-cell electric vehicles (FCEVs) are proven to re-fuel faster, allow higher payload in commercial vehicles, and travel longer distances, all while emitting zero emissions.

A High-Volume, Affordable Fuel Cell Solution

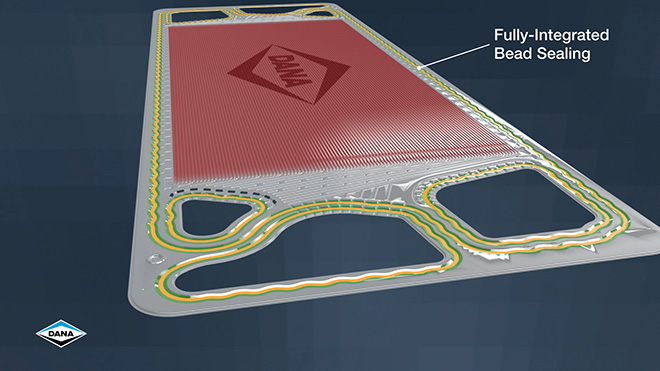

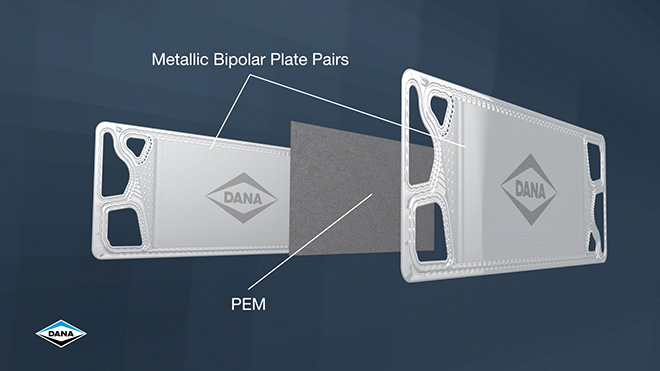

Unfortunately, it’s often perceived that producing fuel-cell stacks is very costly, and it’s feeding the market’s skepticism of the technology’s viability. However, Dana believes in the impact this highly sustainable technology can have on our future — that’s why we’re actively helping to decrease costs with our award-winning metallic and composite bipolar plates. With more than a century of sealing expertise, and fuel-cell plates already in serial production, Dana is a key player in the advancement and commercialization of innovative bipolar plate technologies.

We’ve leveraged our proven design, in-house automation capabilities, sealing expertise, and global manufacturing footprint to bring this high-volume product to market, and we are able to scale our production to industry demand. In fact, we’ve been in serial production for years, and our bipolar plates can be applied in a variety of mobile applications, ranging from light and commercial vehicles, to trains, to marine and aviation applications, and more — across the globe.

From a cost-savings standpoint, our innovative bipolar plate technology combines material coating, forming, and sealing together in a single integrated process. Produced in-house with automated processes, these plates can save OEMs up to 10 percent of the total stack production cost, ultimately making FCEVs a more affordable sustainable mobility solution.

Innovating to Support More Sustainable Vehicle Charging Infrastructure

If we look at vehicle electrification more holistically, the benefits of low- or no-emission vehicles are diminished if we don’t have a sustainable power supply — and integrating renewable energy into the grid is challenging because of its intermittent nature.

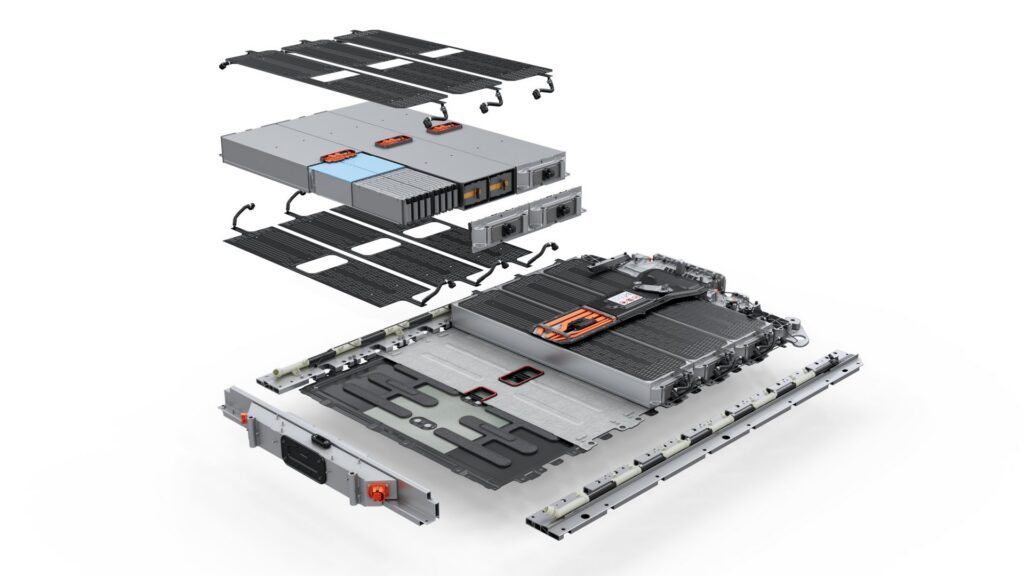

One way the industry is tapping into a more sustainable power supply is by leveraging flow batteries. Flow batteries can store energy generated by renewable sources, such as wind and solar energy, enabling a higher percentage of renewable energy to be integrated into the grid. This drastically reduces the need to utilize fossil fuels to produce electricity used for charging, ultimately reducing the environmental footprint.

So, what do flow batteries have to do with Dana’s bipolar plates? These batteries are charged through a stack that’s similar to a fuel-cell stack. Dana, always exploring ways we can leverage our technologies in new applications and markets, has begun supplying our composite bipolar plates for flow batteries. We’ve grown from supporting automotive applications, to now helping to decarbonize the entire mobility industry by supporting the storage of more renewable energy.

Sustainable Production

Our passion for sustainability extends beyond our product offering. In addition to producing technologies that drive more eco-friendly mobility, we also take steps to ensure that those products are manufactured with the smallest environmental footprint possible.

Just recently, Dana committed to reducing our total annual GHG emissions by at least 50% before the end of 2035. Additionally, we’ve added solar power generation to select facilities, focused on using more responsibly sourced materials, and updated our manufacturing processes to reduce our greenhouse gas emissions, water consumption, and waste. We have also added a standing Technology and Sustainability Committee to our Board of Directors, responsible for providing oversight relating to innovation, new technologies, and sustainability and social responsibility.

A Future-Focused Strategic Partner

Today’s OEMs are looking to work with a manufacturer that not only prioritizes sustainability, but also quality, process, delivery, and consistency. They want a strategic partner — a company that will work together through issues and continue to innovate for the betterment of all.

At Dana, we’ve been doing all of this and more for well over 115 years. We’ve proven time and again that we don’t just reinvent automotive parts to support the future of mobility, we are continually reinventing ourselves, too. We know that electrification is here to stay and, as a result, we’ve invested in research and development, made strategic acquisitions, and established a dedicated electrification team that spans across all mobility markets and regions.

It’s always been our vision to help our customers achieve their sustainability objectives. We’re proud to say that our customers have partnered with us to reduce emissions throughout the entire supply chain and ultimately achieve truly sustainable mobility.

To learn more about Dana’s innovative bipolar plate technology, view the Automotive News PACE award submission video: