A separator is a critical component of any lithium-ion battery, keeping the electrodes apart and avoiding disaster. Porous Power Technologies, profiled in the current issue of Charged, was formed around a new microporous membrane material designed specifically for use as a lithium-ion battery separator.

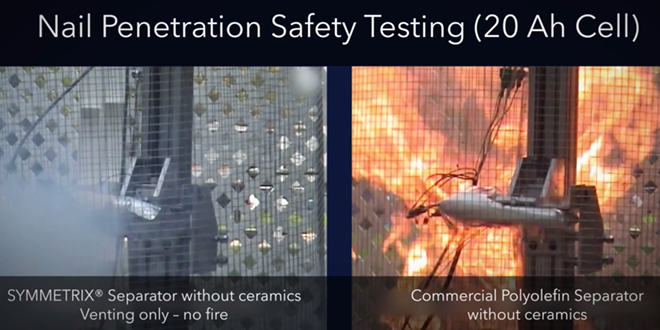

A new video makes the point more eloquently than any technical discussion ever could. Watch what happens to Porous Power’s SYMMETRIX battery separator versus what happens to a conventional polyolefin separator, in the nail penetration test.

Bernard Perry, the company’s Chief Business Development Officer, explained the advantages of its proprietary polyvinylidene fluoride (PVDF) technology. “Most of the battery separators on the market now are polyolefins, either polypropylene or polyethylene,” said Perry. “These polyolefin separators are reasonably good products for smaller electronic applications…but as you start getting into the larger format cell assemblies like electric drive vehicles, you need something more.

“Porous Power’s polymer is not polyolefin. We use an engineering grade PVDF. It’s a very flexible polymer that we solution cast. Because our separator is cast, not stretched, the porosity is very high, exceptionally uniform and stable. We also reinforce the product with a polyester nonwoven scrim. That works like a structural scaffolding to give it tensile strength and help in the battery assembly process. It also provides a skeleton inside the battery separator to prevent the battery from shorting out if the electrodes come in contact.”

Porous Power is now moving into sales mode. “We’re very cost-competitive with the high-end ceramic separators that are offered by the top-of-the-line manufacturers,” said Perry. “Our new ceramic-grade product comes out at the beginning of 2014, and it’s priced to be competitive.”

Source: Porous Power