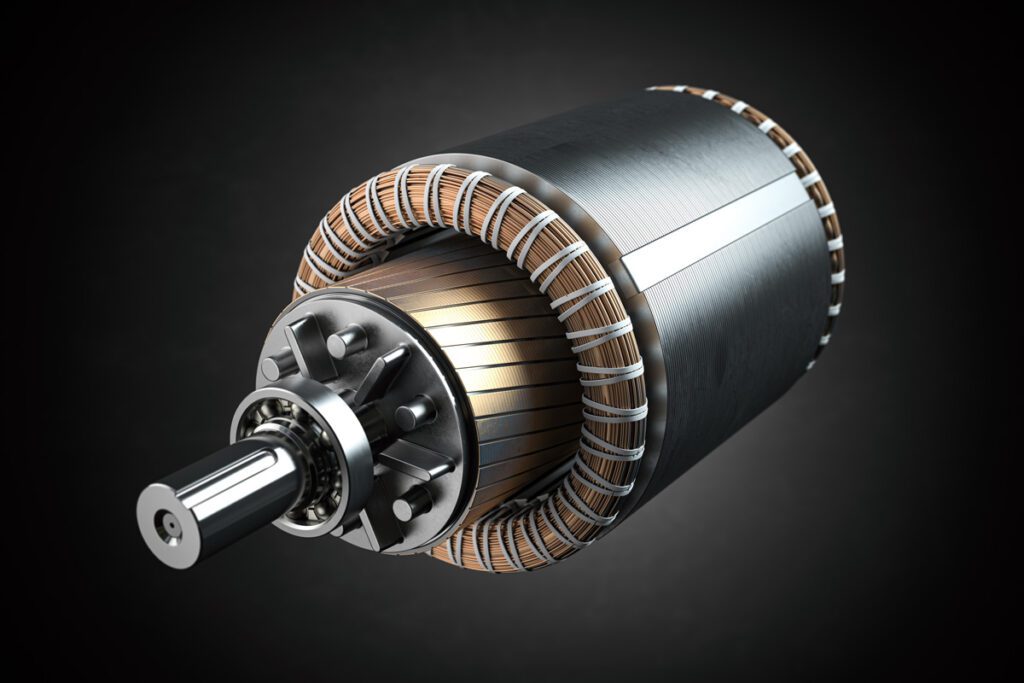

A consortium led by the British motorsport and technology firm Prodrive has successfully run a silicon carbide-based multiport DC-DC converter in an EV. Silicon carbide devices operate at a higher frequency than equivalent silicon components – at 75 kHz in the test vehicles – with a significant reduction in switching losses. This allows the magnetic components to be reduced in size, and has enabled the converter to achieve efficiency of 98.7%, gravimetric power density of 10.5 kW/kg and volumetric power density of 20 kW/liter.

The DC-DC converter acts as a hub that transfers energy between key components of the vehicle’s electrical system. It has four ports: two connect to the traction motor and high voltage battery; a third connects to a secondary energy source, which in this test car is a supercapacitor bank; and the fourth powers the vehicle’s 12 V systems. The converter matches the voltages of these components and transfers energy among them in response to CAN commands from an external controller.

The test vehicle is a Tata Vista EV, which has a 220 V battery and 37 kW traction motor. The vehicle also has two 200 kJ supercapacitor banks, which operate at 75-150 V.

Mark Willows, Prodrive electrical systems and control specialist, said, “In normal driving, the converter boosts the battery voltage to around 400 V to optimize motor performance, and can supplement the battery supply with additional energy from the supercap banks when the driving situation demands it. During regeneration, the converter transfers energy from the motor to the battery or supercapacitor banks as requested by the supervisory controller. Energy can also be transferred directly between the battery and supercapacitor ports. The system can be configured to support other energy sources, such as fuel cells, or could supply multiple traction motors.”

The consortium is now working on a follow-up project that increases the converter operating voltage to 750 V, further increases power density and demonstrates operation at increased coolant temperatures.

“For this project we have developed a rolling test bed based on a light commercial vehicle chassis, which has a 75 kW traction motor. The energy storage consists of a 320 V Li-ion battery and two supercapacitor banks, all of which were built by Prodrive specifically for this project,” said Willows.

Source: Prodrive via Green Car Congress