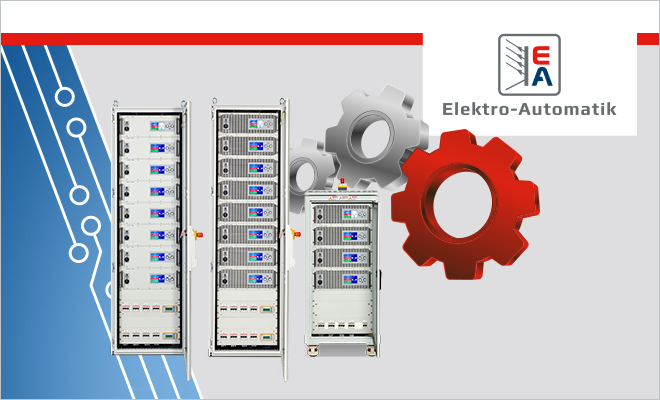

Whether wind energy, solar power or green hydrogen – energy from sustainable and climate-neutral production is becoming increasingly important. The increasing electrification of the world inevitably affects our critical infrastructure. The requirements for the new energy sources in terms of speed of expansion, flexibility and reliability are correspondingly high. To meet these high demands, state-of-the-art power racks are essential. However, the development of such high-performance systems is a demanding and time-consuming challenge. EA Elektro-Automatik has a wealth of experience in the construction of power racks and offers turnkey high performance rack assemblies. We explain in detail how to plan and realize these systems in our whitepaper on EA power racks, download it below.

Self-built power racks: Hidden costs and risks

Numerous applications require significantly higher power ranges than even the most modern power supplies and electronic loads can support. Many users tend to develop their own rack systems without further ado in order to save costs. However, it is important to remember that these systems must comply with standards and safety requirements. In addition, planning and construction are people-, time- and material-intensive and thus become a cost driver that can neither be calculated nor limited without explicit empirical values. In addition, the design of the power racks must be geared to the constantly growing requirements in the area of the energy transition and other future technologies.

Reliable and flexible thanks to modular design

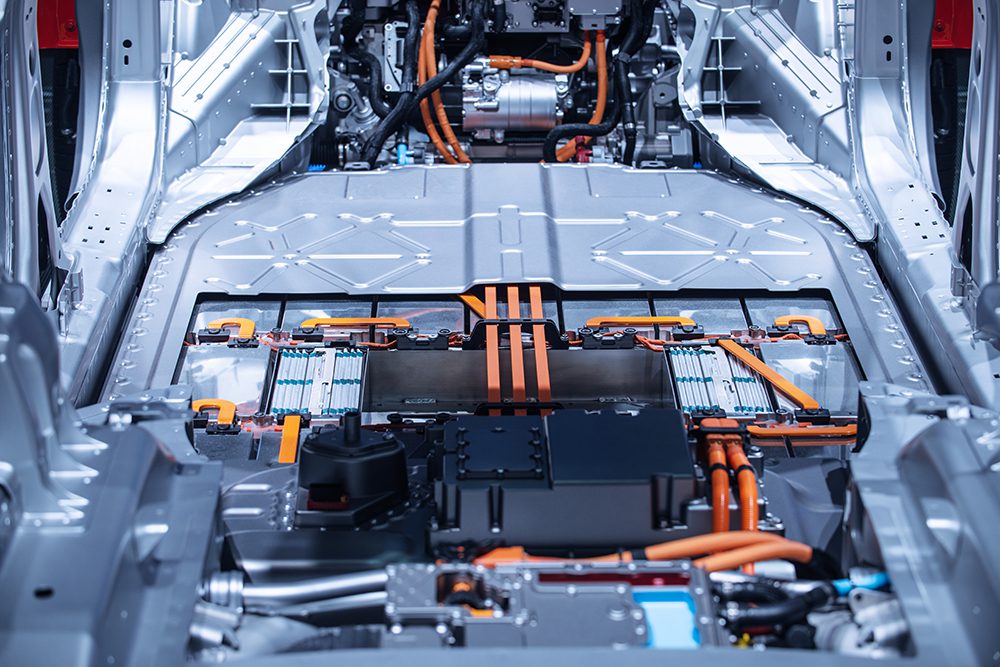

Electrolysis plants that generate green hydrogen from renewable energies represent an example of these new challenges. They must reliably provide a continuous power supply and also operate as a source and load, i.e. bidirectionally. These core aspects naturally also apply to many other applications. To guarantee the functional reliability of power racks, especially within critical infrastructure, modular systems are the means of choice. In contrast to monolithic systems, they offer greater fail-safety, because if one or more modules malfunction, the power supply switches off briefly. The rack then automatically reconfigures itself and continues to supply power with the remaining modules.

Wide range of applications

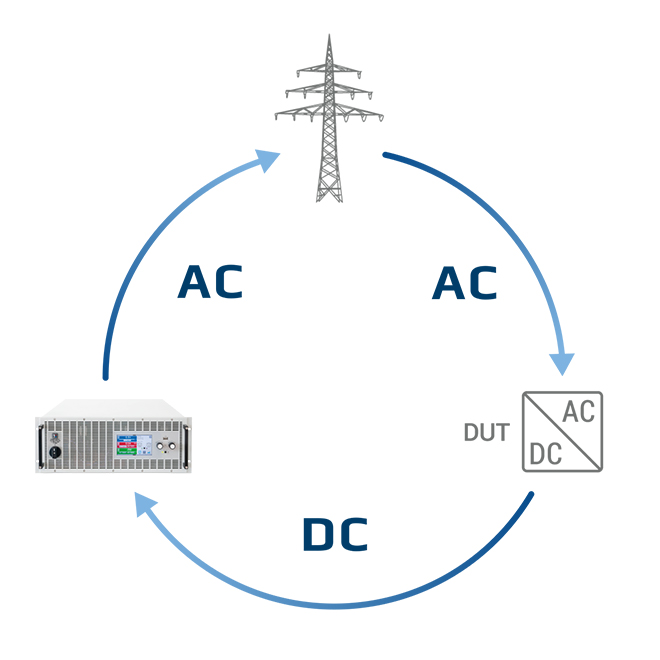

For complex processes such as those in the electrolysis plants already mentioned, power racks not only have to achieve high performance. They must also be able to cover various functions such as operation as a source or load. Ideally, the racks therefore operate bidirectionally and have a power recovery system. Particularly efficient devices such as the EA-PSB 10000 achieve an efficiency of up to over 96%. This means that energy is not only used sensibly, but also that the heating of the devices is reduced, so that costly cooling is not necessary.

EA-Power-Racks: Tailor-made and ready to use

In parallel connection up to 1.92 MW power, bidirectional operation and modular design for maximum fail-safety – EA Power Racks are ideally suited for use in critical infrastructures and various future industries. They meet all requirements such as safety, compliance with applicable standards and are characterized by maximum user-friendliness. They are designed exactly according to customer requirements and delivered turnkey. In our whitepaper, available below, we present the most important functionalities and features and also explain how you can optimally integrate the devices into your processes.