By Kevin Alberts

Vice President and General Manager, Power Signal Solutions Business Unit at Molex

An electrified vehicle future is on the horizon, as global automakers announce new electric fleets and invest in new technologies and EV battery plants to fuel next-generation innovations. Meanwhile, an ever-increasing roster of government incentives and regulations is spurring momentum for consumers, the automotive industry and the environment. The Innovation in Automotive Electrification survey was commissioned by Molex and conducted by Dimensional Research in October 2021, polling more than 200 participants at automotive companies, Tier 1 or 2 suppliers, as well as charging station providers in North America, EMEA and APAC.

The survey findings reinforce the fact that vehicle electrification is about much more than transitioning to electric motors. Consumers expect more from their EVs than just a different engine. They want the safety, value and convenience they’ve come to expect from their cars, along with the unique driving experience, quiet ride, performance and environmental benefits that only an EV can offer.

Companies across the EV ecosystem know that automobile electrification is a complex undertaking, requiring heightened ingenuity, highly sophisticated engineering and fully integrated manufacturing to power next-generation EV innovations. Our survey findings also reflect the need for greater collaboration among automotive OEMs and their suppliers to design and develop new vehicle features—both inside and outside of cars.

Collaboration is Critical

According to market research firm Strategy Analytics, the quickening pace of electrification is causing a step-change in OEM strategy as automakers seek greater access to leading-edge technologies and essential component supplies. As a result, mainstream automakers are partnering with battery-cell vendors, electric-motor developers and semiconductor makers to close skill gaps and gain much-needed experience in these pivotal areas.

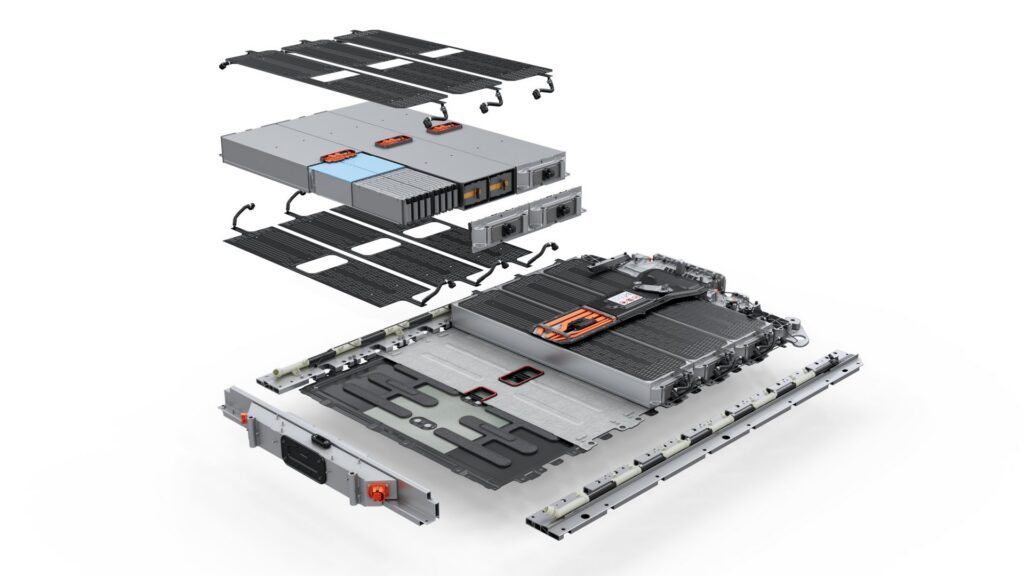

Our survey results reflect this observation, as OEMs cited greater collaboration with Tier 1 or 2 suppliers as the optimal path to innovation. Likewise, suppliers prioritized collaboration, along with increased R&D and capital investments to speed innovation with their OEM partners. In particular, optimizing battery management is on everyone’s minds, as this leads to improved range, performance and charging time.

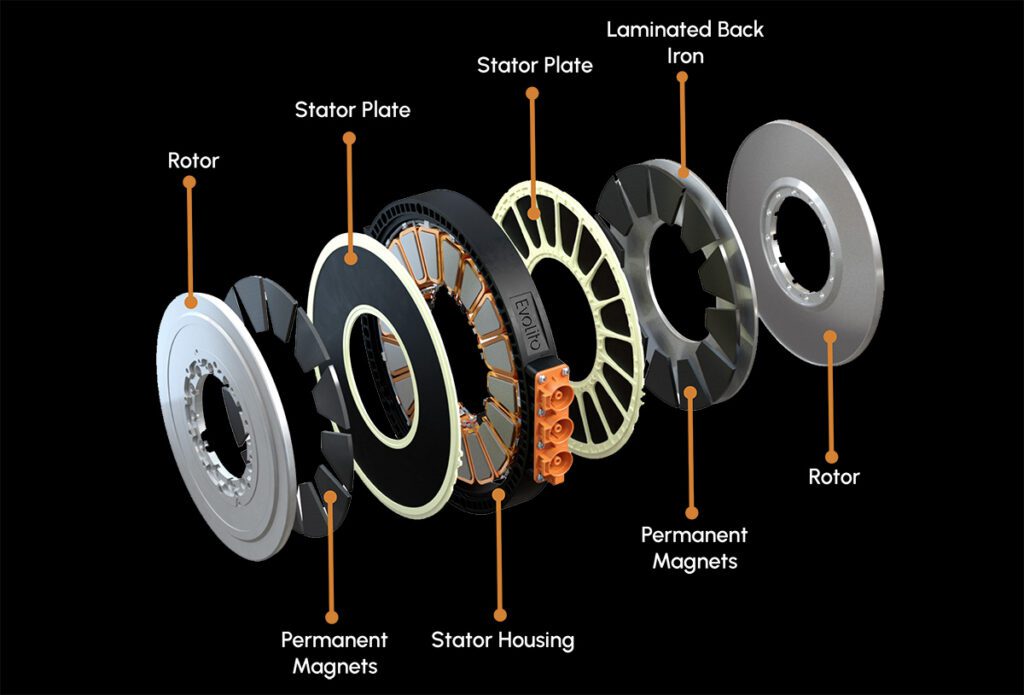

On one hand, participants are having the most success innovating battery cells, modules or packs; electric motors; and powertrain electronics. On the other, respondents report the biggest challenges are improving controller units; wiring, connectors and busbars; as well as cameras and sensors. 92% declared their inhouse design teams are challenged by additional obstacles as electrification efforts intensify.

Topping the list of persistent problems are risks of shock, vibration, loose or damaged circuits, as well as safety threats associated with thermal management and high electrical currents. Internal design teams also must resolve battery-pack lifecycle management and disposal issues, creating opportunities for companies like Molex to clear roadblocks by applying deep and broad experience with power-control units.

Molex is well positioned to drive momentum while helping solve emerging battery management needs, based on decades of providing unparalleled service and custom designs to leading automakers and automotive suppliers, as well as deep power connectivity expertise across a range of industries. When it comes to navigating the fast lane to electrification, continual collaboration will be fueled by seamless access to world-class design, integrated manufacturing, global supply chain, automated assemblies and sustainable capabilities that provide OEMs with a complete end-to-end approach.

In the Auto-Zone

Weight reduction is crucial to improving range in EVs. Today’s vehicles feature long lengths of wires and cables, which can be simplified by a move to zonal architecture. According to our survey, 84% of those polled agree this streamlined approach represents the future for electrified vehicle designs. According to a recent article in Automotive World, almost all OEMs are moving away from deploying 100 or more Embedded Control Units (ECUs) per vehicle to a simpler, centralized architecture leveraging a handful of high-performance computers that minimize ECU usage, installation, weight, and ultimately, cost.

Simplifying the massive web of wires characterized by traditional vehicle architectures is the key to unlocking major efficiencies and simpler manufacturing processes. This is another area where Molex is making major headway by developing solutions that take advantage of core connectivity, power and signal strengths to support specific device and in-line applications for OEMs and Tier 1 suppliers. While 50% of those polled see zonal architecture defining the future of vehicle designs within five years, 34% believe it will take more time before zonal architectures become the de facto standard.

Molex sees the benefits of early customer engagement and proofs-of-concept that validate the value proposition of integrated zonal connectors to help drive the development of future fleets of electric vehicles. Investment Bank UBS projects that EVs will capture 20% of global new car sales in 2025, and 2030 is even more promising with anticipated share predicted to reach 50%. As the latest Molex survey affirms, the race to an electrified future is gaining speed fast, so now more than ever, EV stakeholders need to put the proverbial pedal to the metal to propel this vital industry segment forward.

For more information, contact TTI:

1.800.CALL.TTI

tti.com