Coolmag Thermo Conductive SL presents its CoolMag TM range for thermal management in power electronics and automotive, produced and designed in Barcelona for the improvement of performance and efficiency in Power Electronics

A fatal failure in the power electronics (overheating) usually ends with the car stopped and stranded in technical service, with the costly replacement of the entire functional block; even in some occasions, seeing the car on fire with a very serious reputational damage for the car manufacturers and a serious situation for the owner.

Most of the problems that affect lithium batteries in electric vehicles (pressure, heating, short circuits, fire hazards) are also common to power electronic circuits and therefore the same solutions apply.

The enemy is the air, and we must reverse the old paradigm in thermal management:

- Why are air and plastics still so present in power electronics?

- Why are many of the structural components still thermal insulators?

- Why until now has thermal conductivity always been more influential than thermal resistance or thermal diffusivity?

- Why haven’t 3D designs been used yet to manage thermal conductivity in power electronics?

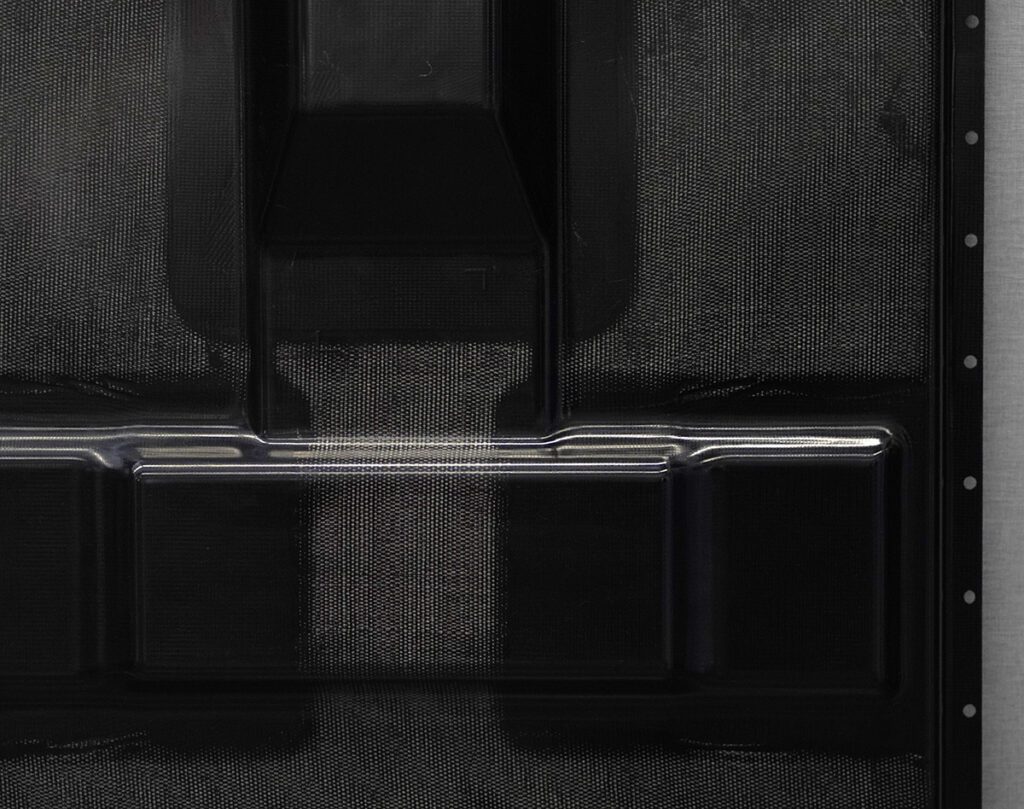

- Why do Li batteries still allow air between their cells?

Transformers and electronic chokes for on-board chargers (OBC) and power inverters in electric vehicles must handle very high power for very short periods of time and at very high densities. Meanwhile, batteries double their capacity and charging times are increasingly reduced due to demands for improved mobility. Likewise, the power electronics circuits of electric vehicles increase their effectiveness and reduce their volume equally. This continued demand for more power at lower cost, weight and volume is pushing electronic engineers to design to the limit and in record time. At Coolmag CT SL we have developed and designed with non-linear models based on 3D, passive elements for thermal management based on silicon, manufacturing thermosetting elastomeric compounds that are easy to apply and that affect both the thermal conductivity and the thermal diffusivity of the whole; the capacity and the speed at which heat can be dislodged, so that whether it is an OBC, a DC / DC converter, a battery or any magnetic, we can reduce the working temperature by up to 40%, significantly improving both the performance as the life of materials.

We offer an all-in-one solution, from 3D design of the precast and/or moulding to final customized dispensing machines for best and smoothly product potting

Contact us at admin@coolmag.net, call 003493 480 91 87 or visit www.coolmag.net and/or www.linkedin.com/company/coolmag/mycompany/ and ask our technicians how to improve your thermal management.