ZEISS eMobility Solutions Delivers Quality Solutions

The automotive industry is rapidly accelerating development and release of new electric vehicles. And since the construction of electric powertrains differs significantly from those of combustion engine vehicles, companies are being forced to adapt the production and assembly of critical electric vehicle components as well. A major challenge in quality assurance today is the need to meet the increased demand for precision.

Achieving more power, less weight and longer range are important targets in the design and construction of electric vehicles. At the same time, manufacturers are faced with the question of how to manufacture electric powertrains efficiently. While mechanical processes such as milling, rotating and grinding prevail in the manufacture of combustion engines, the predominant methods used in the production of electric motor stators are punching, bending, welding and impregnation. This has implications on the quality assurance process.

Flexible quality solutions

Production requirements are bringing about changes to the traditional dimensional measurement of components of the electric motor. While tolerance margins are in fact widening in some cases, production is also complicated by limited accessibility and a high number of properties. New critical requirements for weld seams, such as the need for seems to be free of defects, and even the thickness characteristics of impregnation coatings are likewise important contributors to the difficulty of manufacturing electric engines.

This demands quality assurance solutions that are significantly more flexible and diverse, not only in sensor systems, but in software and analysis as well. Evaluating weld seam inspections requires coordinate measuring machines with tactile and optical sensors, as well as computed tomography scanning. Ground weld seams also need to be analyzed under the microscope. ZEISS eMobility Solutions offers a wide range of solutions for this, paired with the ability to link results through ZEISS PiWeb, thus providing manufacturers with more efficient control over their production.

Fuel Cell Solutions

In addition to Battery Electric Vehicles (BEVs), Fuel Cell Electric Vehicles (FCEVs) are another possibility for the future of alternative energy supply. In a FCEV, the fuel cell system provides all of the energy needed to power the electric motor. The fuel cell stack is the most important component of the FCEV, this is where energy is being provided through electrochemical reactions. In the fuel cell stack many individual cells are arranged in series and connected together. The process to construct the fuel cell system requires the highest quality standards in production and development of each individual component. These requirements can be achieved by using ZEISS microscopy and ZEISS metrology solutions.

Quality assurance for fuel cell vehicles

At the heart of every fuel cell vehicle (FCEV) is a stack of individual low-temperature fuel cells with polymer membranes (PEMFC), which generate electric energy from hydrogen. Each cell is comprised of two bipolar plates and a membrane electrode assembly (MEA).

Fuel cells are connected in series, which means that the quality of each cell is responsible for the performance of the overall system. The requirements placed on bipolar plates and MEAs can be met by means of dimensional metrology, as well as by inspecting coatings and surface defects, including contaminations and weld seams.

Operators therefore use a variety of measuring machines and imaging processes to cover the full range of quality requirements within the fuel cell manufacturing process. ZEISS solutions such as the multi-sensor coordinate measuring machine O-INSPECT, the computed tomograph METROTOM, and Axiolmager light microscope make it possible to achieve this level of quality assurance. The comprehensive ZEISS PiWeb software and uniform software design of each ZEISS solution ensure that manufacturers can track and record measurement results by generating individual reports for each component.

Battery Solutions

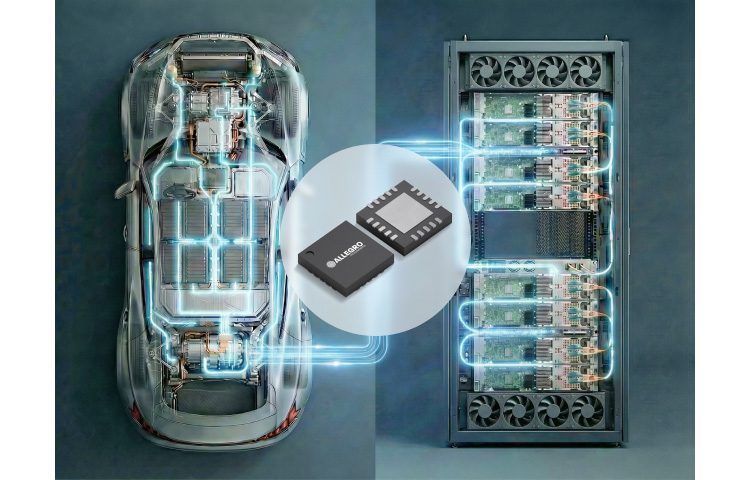

Batteries play an important role in the performance, range and longevity of an electric car. Safety, service life, performance and cost are essential to ensuring the success of battery technologies – both today and in the future. These factors need to be addressed every step of the way, from R&D to quality control and production. It’s necessary to control and understand the properties of the battery down to the material, electrodes, cells, modules and tray level.

To produce efficient, reliable batteries that last, it is necessary to use top-quality materials and precise production techniques. Quality criteria range from selecting the best possible materials – including Lithium compounds, anode and cathode materials and separator foils – to control critical steps during the electrode manufacturing process. Understanding the microstructure and possible sources of contamination is key. It’s also essential to build cells, modules and trays within very tight tolerances during final assembly.

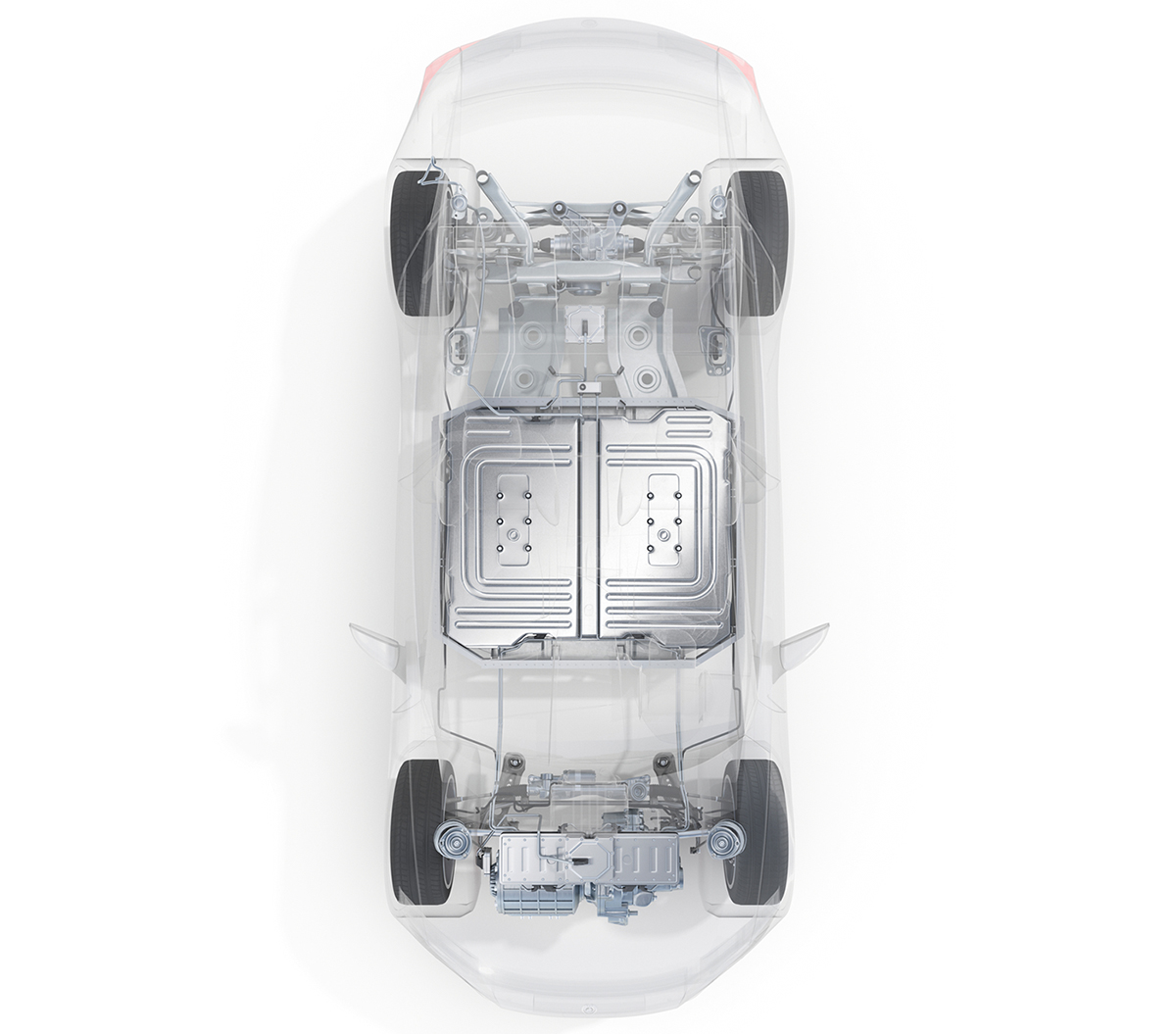

The battery tray challenge

Alongside the powertrain, the chassis of the electric vehicle is also undergoing significant production changes – as can already be seen in the manufacture of battery trays. In battery electric vehicles (BEVs), the battery tray consists mostly of a complex welded aluminum profile. Plug-hybrids (PHEVs) frequently use smaller cast constructions. These various system requirements are translated into quality requirements in the form of geometric properties, such as the position, form and location of individual component properties. The size of the battery tray in particular, and hence the large number of properties such as positive fitting, poses a challenge for measurement cycles. And since this is a safety-critical component, a 100% inspection is required in most cases.

ZEISS has a wealth of experience in inspecting battery trays. ZEISS PRO T horizontal-arm machine (HAM) with ZEISS EagleEye laser scanner is often used for this purpose. The ability to automatically switch between tactile and optical sensors within a single inspection plan makes it possible to access the most diverse points of measurement and to perform reliable and reproducible measurements. Once the various component characteristics are measured, the analysis results can be illustrated visually in the application software and in ZEISS PiWeb. The GOM ATOS ScanBox is also well-suited for measuring battery trays thanks to its high level of automatability and its use of structured-light 3D scanning.

Download Brochure to learn more

ZEISS Industrial Quality Solutions

Zeiss.com/metrology

1-800-327-9735