We all know Elon Musk and company are used to thinking big. Even so, the recent announcement that a Tesla Semi truck would be unveiled in September caused jaws to drop and heads to shake. In the trucking industry, there was plenty of skepticism, but also a healthy concern for the future. “Commercial vehicle makers – and their suppliers – would be wise to stymie their laughter and take [this news] seriously,” wrote analyst Alex Potter.

Is an electric semi truck even practical? The hurdles are huge. On-road trucks must haul tons of cargo over long distances in all weathers, so a viable EV would need massive power, long range and durability, not to mention that there is no highway charging network suitable for heavy-duty vehicles, and little incentive for operators to switch from cheap diesel fuel.

However, Tesla’s truck is no idle threat – it’s a working prototype. During a recent conference call with stock analysts, Musk said he had taken a test drive around the parking lot, and that the truck “feels like a sports car.” He assured us that the e-truck will be capable of long hauls, and that the cost of operation will be low enough to make it an attractive replacement for legacy diesel trucks.

CTO JB Straubel said the Tesla Semi wasn’t especially complicated, technically speaking, and Musk explained that it shares “a lot” of parts with Model 3, including “a bunch” of the new Model 3 electric motors. Neither said much about the battery pack, but there’s no doubt that it’s going to be big – perhaps the largest pack ever installed in a production vehicle. Did we mention that it’s big? [“How big is it?” shouts the audience in unison].

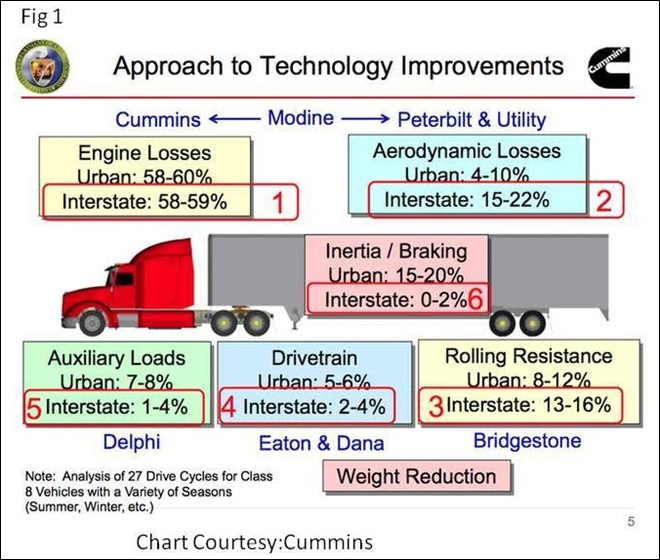

Well, there’s been a lively discussion about that over at InsideEVs, with writers and commenters doing some “napkin math.” A chart from engine builder Cummins illustrates the various factors that affect the fuel economy of on-road trucks. Together with truckmaker Peterbilt, Cummins has been developing a fuel-efficient SuperTruck that has demonstrated fuel economy of an impressive 10 mpg.

Assuming optimal aerodynamics, rolling resistance, etc. and accounting for the greater efficiency of electric motors, as well as regenerative braking, the envelope engineers estimated that an electric semi would require a 1,200 kWh battery pack to achieve a range of 600 miles. At a cost of $100/kWh, which Tesla hopes to reach soon, that would be a $120,000 battery. According to a 2016 article from AskTheTrucker, the cost of a new diesel-powered tractor starts around $113,000, and annual fuel costs are “easily more than $70,000.”

Perhaps a simpler way to go about estimating the battery size for a Tesla truck would be to look at heavy-duty vehicles already on the market. Electric buses from several manufacturers are running in revenue service in cities around the world (in China, cities are ordering them by the thousand). The biggest have battery packs of around 400 kWh. However, e-buses aren’t directly comparable to trucks – their human cargo is much lighter than the 34,000 pounds that a tandem-axle trailer may carry, and they typically have a range of less than 100 miles.

Tesla won’t be the first company to produce an electric semi truck. In fact, electric Class 8 electric trucks from BYD have been in pilot operation for some time, and Orange EV Class 8 trucks have been commercially available for more than 3 years. However, these are terminal trucks (aka hostlers or yard goats), which are used for cargo handling in and around ports and other freight facilities. They haul the same loads as highway trucks, but do not need to have a very long range.

Chinese EV-maker BYD also offers a Class 8 semi truck for on-road use. The BYD T9 has a 188 kWh battery pack, and a stated range of 92 miles. Andy Swanton, Vice President of BYD’s Truck division, told Trucks.com that medium- and heavy-duty electric trucks make up an increasing part of BYD’s commercial vehicle business, and that the company has sold about 150 electric trucks to US customers (the company also sells electric delivery vans to UPS and others). We don’t know if the company has any actual orders for its on-road semi yet – Swanton said only that it is “already in service in China.”

Source: InsideEVs