China-based chemical materials firm TRUNNANO has announced a breakthrough in the production of high-purity spherical aluminum nitride (AlN) powder, which it says overcomes long-standing technical challenges.

The powder’s thermal conductivity makes it ideal for thermal interface materials in EVs, where efficient heat dissipation is critical. It also enables high-performance ceramic substrates for power electronics and supports additive manufacturing of complex, heat-resistant components.

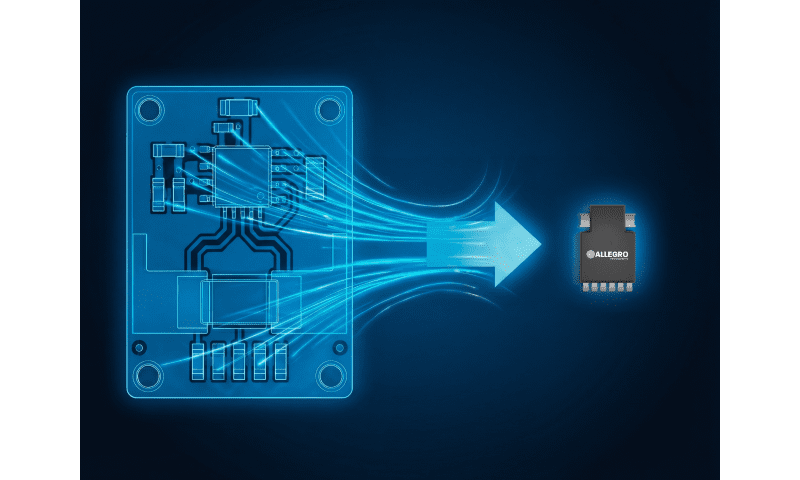

The company has developed a synthesis method to ensure superior sphericity, uniform particle size distribution and high thermal conductivity, which are key properties for electronic and ceramic applications.

Spherical aluminum nitride powder is used in semiconductor packaging, high-power LED cooling and advanced ceramics, for its thermal conductivity and electrical insulation properties. However, conventional production methods often result in irregular particle shapes, agglomeration and impurities, which can affect performance. AlN’s tendency to oxidize degraded its thermal properties, while scaling lab techniques to industrial production posed consistency issues.

TRUNNANO has developed a plasma-assisted synthesis technique that achieves 99.5% purity, minimal oxygen content, tightly controlled particle size distribution and exceptional sphericity to enhance flowability and sintering performance.

“Our spherical AlN powder represents a leap forward in material science,” said Roger Luo, CEO of TRUNNANO. “By solving the sphericity and purity issues, we’re empowering industries to push the limits of thermal management and device miniaturization.”

Source: TRUNNANO