With the significant growth and development of battery pack technologies, manufacturers of Electric Vehicles (EVs) are placing an increased emphasis on pack design optimization. Manufacturers seek lighter weight, yet more compact solutions to gain additional energy density and reduce cost. In parallel, they also strive for simpler and more affordable manufacturing operations. One immediate route to achieving these goals is the elimination of the housings of battery modules and bonding individual cells directly to the cooling plate, a strategy known as “cell-to-pack” [1-3]. Longer term solutions, albeit mostly conceptional, even involve bonding cells directly to the vehicle chassis [3-4]. To address these emerging trends, new thermally conductive adhesive technology is needed, especially given the imposition of more demanding environmental and mechanical performance conditions.

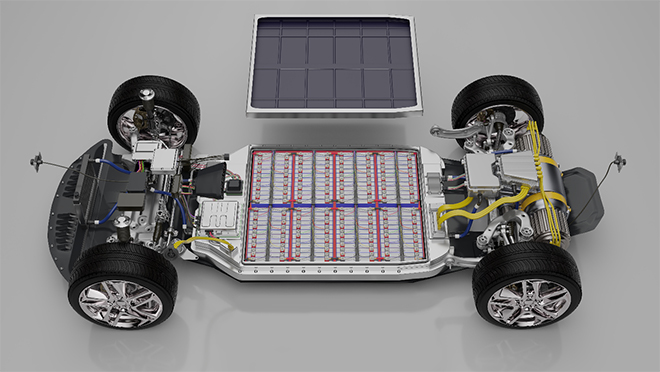

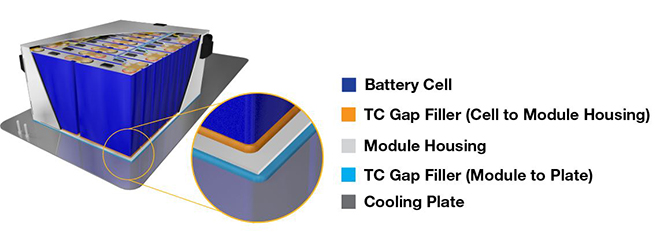

Driven by highly stringent safety standards coupled with affordable and abundant supply chains, a majority of EV manufacturers have converged to a common battery pack configuration (see Figure 1). This battery pack configuration consists of numerous battery modules, each of which contains groups of individual battery cells. This approach enables control, monitoring, and service of discrete battery modules. It also provides the batteries with additional crash and environmental protection, incorporates greater electrical isolation between and around modules, and, in-turn, helps prevent fire propagation in the event of thermal runaway. From a thermal management standpoint, a minimum of two discrete thermal interface materials (TIMs) or “gap fillers” (GF) are typically employed in the current, modular-based, battery pack configuration, as illustrated in Figure 2.

Both gap fillers, with the aid of a liquid-cooled plate, help regulate the temperature of the modules to ensure safe and efficient performance. The upper gap filler fills in the large spaces or gaps between the lower sides of individual batteries and the gaps between the bottom of the batteries and the inside wall of the module housing; this serves to firmly adhere the batteries in place while providing a continuous, thermally conductive (TC) pathway through which heat can travel. Such a gap filler, referred to here as a Cell-to-Module (CTM) gap filler, is often based on chemistries such as urethanes that offer strong adhesion, yet good flexibility to help absorb stresses.

The lower gap filler fills in large spaces between the cell modules and the large cooling plate for the entire battery pack (see Figure 2). This material, referred to here as a Module-to-Pack (MTP) gap filler, also serves to provide heat conduction between the adjacent interfaces, but unlike the CTM gap filler, is designed to lightly adhere to the cooling plate surfaces. The low bonding strength enables easy removal of discrete modules for serviceability reasons. MTP gap fillers are typically based on very compliant, chemical backbones, such as silicone or soft urethanes.

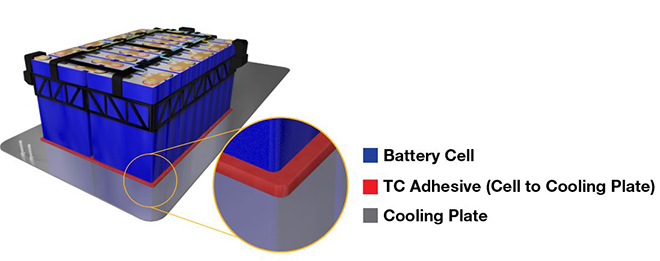

Despite the many benefits of the conventional modular design, there comes numerous tradeoffs. For example, the inactive portions of the module (e.g. the housing, terminal plates, side plates, internal connectors, controls, etc.) add weight, occupy precious volume, and ultimately translate in compromised pack energy density. Moreover, the many discrete parts increase complexity of the design, manufacturing, and supply chain logistics. Given these challenges, many EV and battery manufacturers are eliminating modulus entirely and directly bonding batteries to the cooling plate as illustrated in Figure 3.

This new module-free approach, referred to as “Cell-to-Pack” (CTP), reportedly increases volume-utilization space from 15-50%, depending upon battery cell design [1-2]. Moreover, the number of parts is claimed to be reduced up to 40% [2]. This change not only greatly improves pack energy density, but also gives EV manufacturers the option to use less expensive, lower energy density cells given the extra space.

From a thermal management standpoint, the new CTP design results in half the thermal interface materials (1 vs. 2), half the number of interfaces (2 vs. 4), and no module housing. This change greatly lowers the thermal resistance of the stack which offers reduced cooling (or heating) loads by the cooling plate and/or enables the use of lower conductivity gap fillers. On the other hand, this change has invoked more stringent environmental resistance and mechanical performance requirements since the module housing is no longer available to protect the batteries from the environment. For example, numerous OEMs are now requiring thermally conductive gap fillers capable of maintaining strong, flexible bonds between polyethylene terephthalate (PET) wrapped battery cells to aluminum-based cooling plates after 1000 hours (6 weeks) of aging at 85°C and 85% relative humidity (RH). The PET is primarily used to provide individual, prismatic cells an additional layer of electrical insulation to prevent electric arcing.

To address this CTP trend and associated requirements, Parker LORD has been developing new adhesive technology. Their latest white paper highlights recent developments for thermally conductive, CTP urethane adhesives. Urethane chemistry, in a 2-part form, was selected due to its good balance of strength, ductility, and formulation versatility. Specific attention is devoted to adhesive performance on PET plastic and aluminum substrates with environmental aging in mind. Comparisons to conventional urethanes are made. Additional properties such as rheology, density, conductivity, and bulk mechanical properties are briefly discussed.

Cell-to-Pack Adhesive Innovation

As previously mentioned, new CTP designs are requiring adhesives to maintain excellent adhesion under more stringent environmental testing conditions given the lack of the once protective modular housing. It is not uncommon for CTP pack designers to require lap shear strength levels in excess of 6 MPa after exposure to 1000 hours of 85°C and 85% RH. Historically, urethane adhesives have often had difficulty maintaining high levels of adhesion particularly on plastics and aluminum substrates after extended exposure to 85°C and 85%RH. Adhesives containing high levels of thermally conductive filler pose an even a greater challenge.

Through unique formulation developments in their laboratory, Parker LORD has been able to achieve noteworthy results after extended 85°C / 85%RH aging. Their new CTP adhesives are capable of delivering a balance of rheology needed for ease of manufacturing, low density for light-weighting of vehicles, good thermal conductivity for effective battery heat management, strong bulk properties to assist in handling mechanical loads, and low dielectric constant to prevent electrical charge buildup. Moreover, their scientists and engineers can tailor CTP adhesive performance to meet the requirements of specific CTP applications.

Click here to view the whitepaper which contains data and complete test results comparing cell to module gap fillers and new thermally conductive cell to pack adhesives. If you have a specific question, reach out to a member of their team today.