Litarion, a subsidiary of Electrovaya Inc, has introduced a new, thinner flexible ceramic separator for utility-scale and EV applications.

Among all cell components, the separator, is responsible of preventing the contact between the electrodes while permitting a free transport of ions in the cell. Its properties are also closely related to cycle life and cell performance in general.

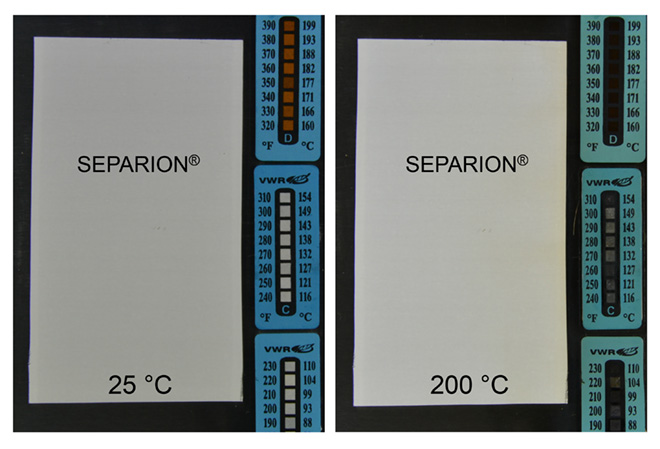

Separion is a flexible ceramic separator in which ceramics and a porous polyethylene terephthalate (PET) non-woven form a homogenous single-layer network. With the addition of Separion P20 to the product line, Separion separators are now available in nominal 21 micron (P20) and 28 micron (P30) versions.

Separion claims to outperform trilayer polyolefin and other ceramic-coated separators, and is designed for high temperature stability, which enables cells to improve their safety performance, especially on the nail test. Due to its unique structure, the company says it provides mechanical integrity up to 240 °C and a very low shrinkage of <1% at 200 °C, even when applied for several hours.

Separion is designed to save time and costs in the manufacturing process. Cell stacks containing Separion can be dried at high temperatures without melting or shrinking, and Separion’s wettability characteristics are meant to minimize electrolyte filling time and pressure.

According to the company, Separion has been used in more than two million large-format lithium-ion cells, and the new P20 is now being qualified with several customers with positive results.

Source: LITARION via Green Car Congress