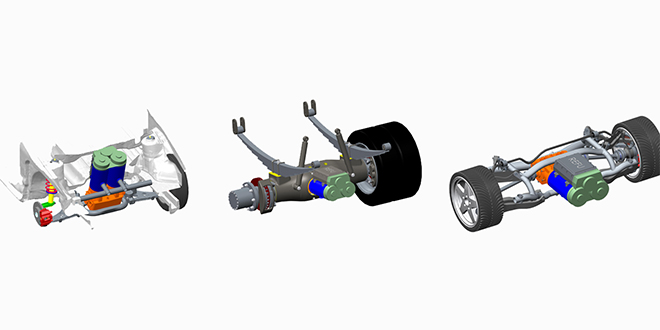

A group of eleven German partners, including the Fraunhofer Institute, is developing an integrated axle module for commercial vehicles that promises high performance and reduced production costs. ESKAM, which stands for Electric Scalable Axle Module, includes a motor, gearbox and power electronics in a single compact housing.

Advantages of the axle module include high power density and high torque, which means fast acceleration. The ESKAM motor achieves speeds up to 20,000 rpm. “When we started on the project three years ago, we were the only ones who could obtain such high speeds,” recalls Project Manager Dr. Hans Bräunlich. “Our head start in accumulating development experience has given us a technological edge, which we intend to further extend.”

The researchers also developed some innovative series production technologies that could offer even greater advantages. “Thanks to the innovative concept, there is great flexibility when manufacturing the modules – for small quantities and large batches alike,” says Bräunlich, adding that production costs could be reduced by up to 20 percent.

For example, the gearbox shafts are manufactured using a method called spin extrusion. “To help visualize the process, think of pottery,” explains Bräunlich. “The material is extruded during the shaping process, and pressed outward in a longitudinal direction. This allows us to use virtually all the material, cutting material costs by approximately 30 percent and reducing the overall weight of components.” The gears are made using a special forming process called gear-rolling, which does not produce any metal chips, and loses almost no material.

“Because the module is scalable, we can use it in everything from small vans and municipal vehicles to buses and trucks,” says Bräunlich. With a wheel hub motor, that would not be possible, he explains. While wheel hub motors have definite advantages – such as a wider steering angle and greater responsiveness – they are not suitable for commercial vehicles, as they scarcely deliver more than 2,000 rpm. Since each wheel also requires its own power electronics, costs are higher. “Both developed versions have their own clear raison d’être and should be chosen specifically for a planned vehicle type,” says Bräunlich.

The consortium is now putting the individual parts together to make a demonstrator. They want to fit the axle module into a real car for testing by the end of 2015.

Source: Fraunhofer Institute