Australian mining company Renascor Resources has completed equipment trials for its planned purified spherical graphite (PSG) manufacturing facility in South Australia.

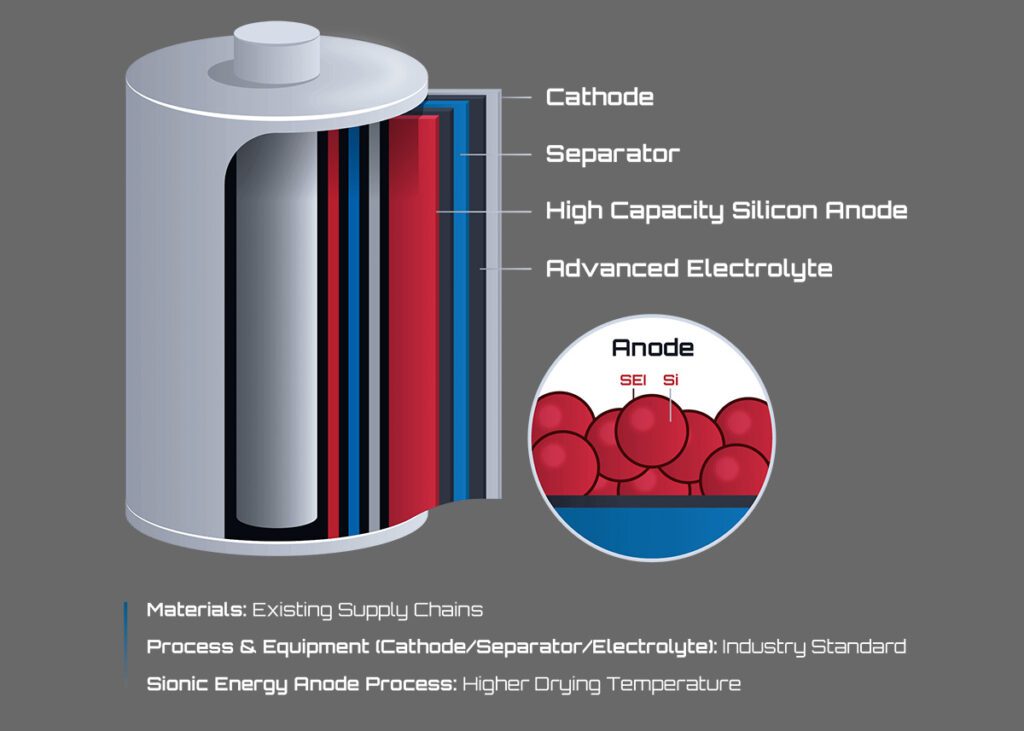

The trials produced graphite of the quality required for lithium-ion battery anodes across all targeted product specifications up to 99.99% carbon—compared with the anode industry standard of 99.95% carbon. The tests were also below industry impurity standards. This further validated Renascor’s hydrofluoric (HF)-free purification process and provided detailed equipment specifications for the facility, according to the company. The company has commenced engineering for the demonstration facility, which is scheduled to start commissioning in Q2 2025.

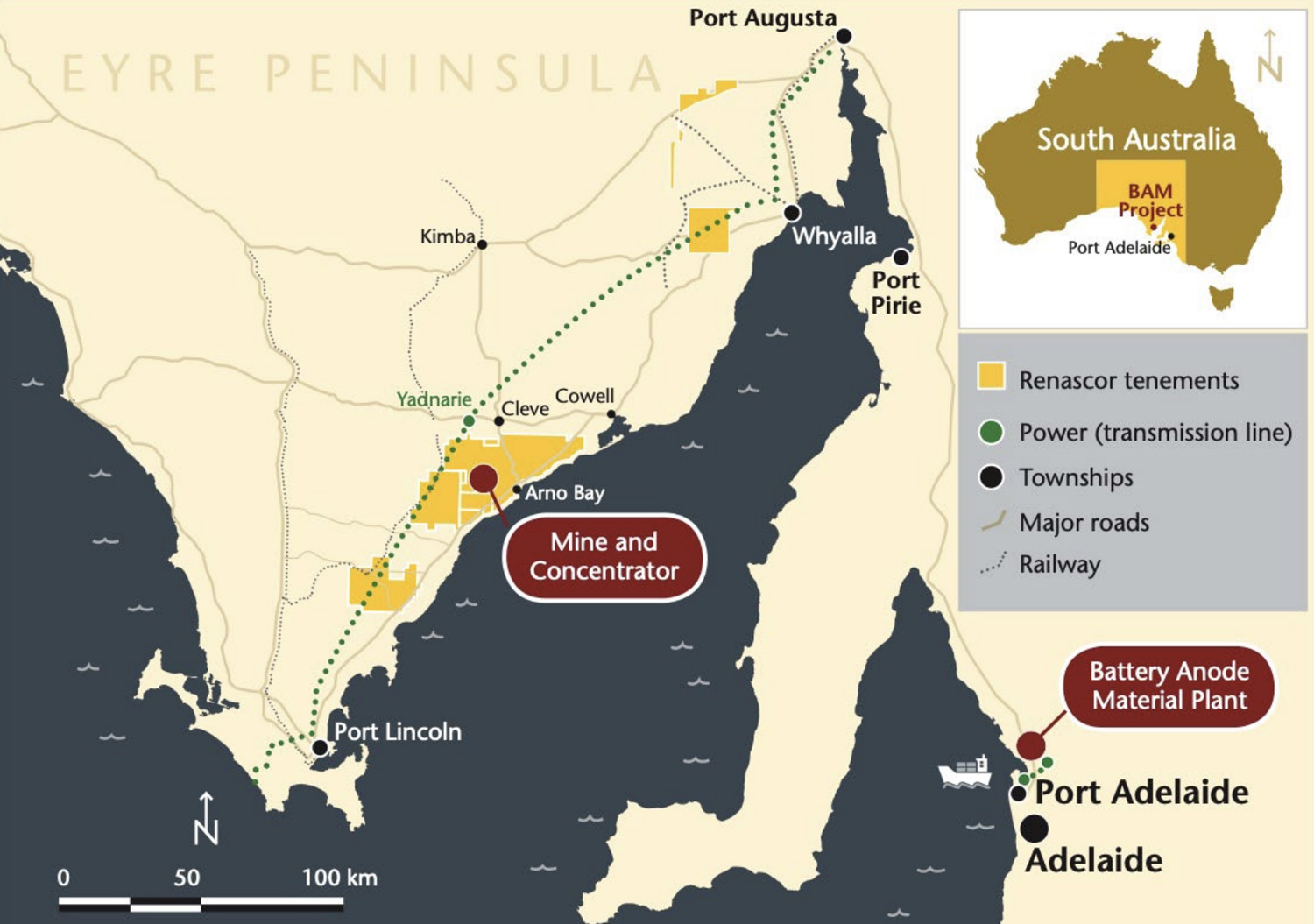

Renascor is developing vertically integrated battery anode material (BAM) production in South Australia comprising a graphite mining and processing operation and a downstream BAM facility that will refine graphite concentrates into PSG for export to lithium-ion battery anode manufacturers.

“Renascor’s HF-free purification technology has the potential to deliver a globally competitive PSG operation and advance Renascor towards its goal of becoming a long-term producer of high-quality graphite products to the lithium-ion battery sector,” said David Christensen, Renascor’s Managing Director.

Source: Renascor Resources