US-based lithium battery technology company Pure Lithium has signed a strategic agreement with Canadian firm Kingston Process Metallurgy (KPM) to collaborate on the scaling, design, construction and commissioning of Pure Lithium’s pilot-scale lithium anode production reactor.

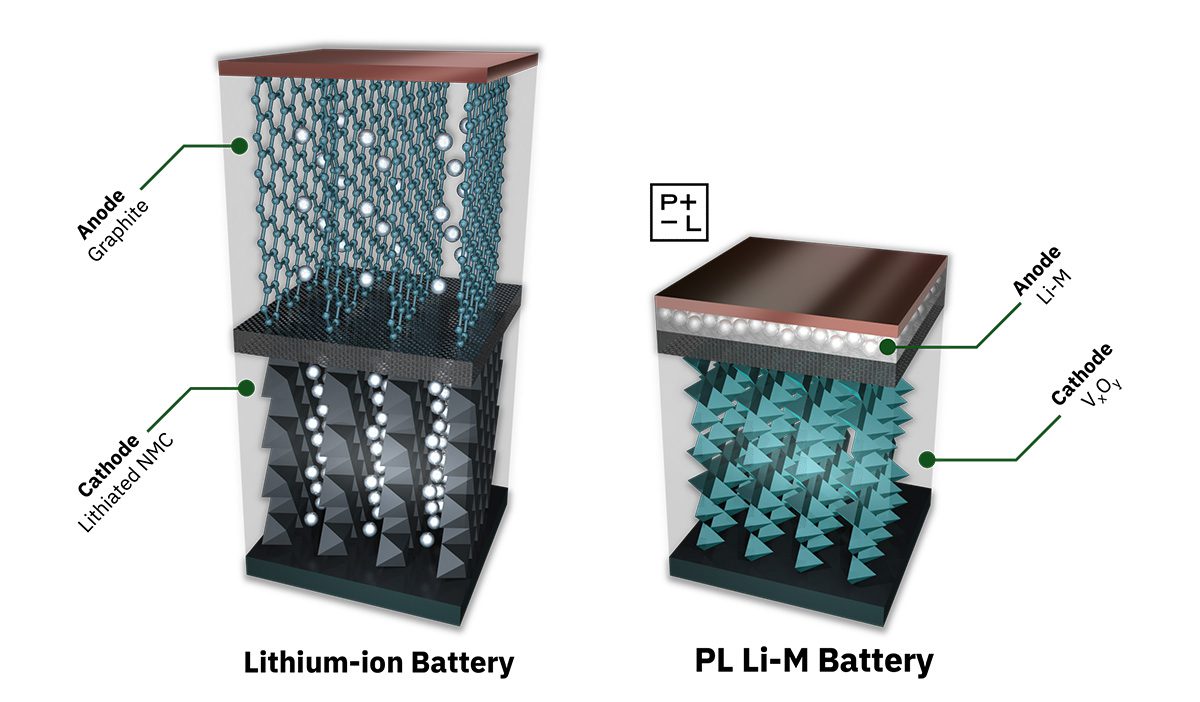

Pure Lithium is advancing a lithium vanadium oxide battery enabled by a scalable and cost-effective lithium metal electroplating process, which it calls “Brine to Battery,” that bypasses traditional lithium compound production.

The company is working with KPM, which is experienced in designing and optimizing complex chemical and metallurgical systems, to develop a fully integrated demonstration reactor capable of producing highly pure lithium metal anodes of varying thicknesses.

The reactor will demonstrate the technical and economic viability of Pure Lithium’s process, which encompasses selective lithium extraction, electrochemical plating and material recycling. The project sets the foundation for future pilot plant and commercial development.

“Our lithium metal anode technology was a necessary first step to commercializing our lithium metal batteries. Without this technology at scale, these batteries would never reach commercialization due to the high cost and low quality of lithium metal produced by existing methods,” said Emilie Bodoin, Pure Lithium founder and CEO. “The team at KPM will play a critical role in scaling our lithium electroplating technology into a fully operational pilot-scale reactor.”

Source: Pure Lithium