By Carlos Castro, Global Director Marketing Automotive Electronics, Littelfuse, Inc.

As hybrid and electric vehicles roll closer to battery power drive systems with 48V or higher, the lithium-ion battery in a closed system is the clear leader for power. Lithium-ion gets high marks in cost, energy efficiency, temperature performance, power-to-weight ratio and lifecycle. Part of the success includes a robust battery management system (BMS), which maintains the safe operation of the high-voltage battery and relays battery information to the power and energy management systems.

Lithium-ion batteries are not the prima donna of battery power, but they do require attention in monitoring and protection. Reliable battery operation is only possible with a state of charge maintained between approximately 20 to 90 percent of the maximum. High discharging and overcharging reduces the efficiency and the lifespan. Excessive current flow causes shorts and dendritic plating, which destroys the cell. Undervoltage may cause shorts or breakdown in electrode materials. Excessive temperature can trigger a chain reaction of events, from shorts to the outgassing of flammable gases from organic solvents. For all these possibilities, designers employ battery management systems that prevent costly and potentially dangerous battery failures.

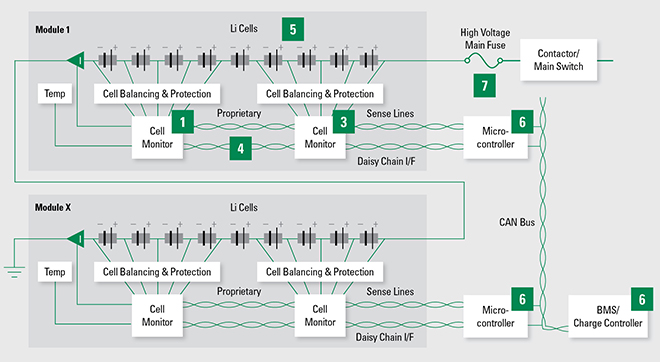

With these parameters for efficient and safe operation, the battery management system needs protection from threats such as overcurrents, surges and ESD. Fuses, TVS diodes and diode arrays maintain safety and stability—from the assembly process to maintenance and normal operation.

Circuit protection is mission-critical in hybrid and electric vehicles employing a very high-energy system that operates at hundreds of volts and amps. In the case of an accident, a damaged, crumpled or punctured battery can lead to a thermal incident or contact with the metal chassis of the car. While design engineers seek to eliminate the possibility of such events, doing so requires knowing which fuses to use and where to put them. Protection goes beyond performance and extends to the safety of the consumer as well as the company’s image and reputation.

As vehicle designers work to maximize economies of scale from a multitude of approaches, a single best practice has not emerged. A new generation of design engineers are introducing new voltage classes, new architectures and new ways to adapt their operations from mechanical to electric.

The fuses used in these applications must meet automotive-specific reliability criteria and testing standards. Fuses should have a low-temperature derating. Unlike “mobile” batteries in cell phones or tablets, these fuses must adapt to temperature cycles and vibrations. The small form factor is essential. The design needs to incorporate a life cycle of fifteen years, more than 150,000 kilometers of road vibrations and 8,000 hours of operation.

The battery management system’s voltage range and interrupt rating requirements depend on the battery configuration. Within the system, each module of batteries has cell monitoring systems. These subsystems monitor the voltage for proper balance. Microcontrollers then oversee each of these modules to provide the highest energy efficiency and longest life of a battery.

For the creators of a high-voltage battery management system, there are fundamental building blocks in the design. The cells are connected in series, making up a module. As modules connect in series, the total voltage of the system increases. The series of modules, connected in parallel, increase the energy capacity of the battery. As cells and modules are added to a battery management system, the complexity and cost increases. The challenge is to find the correct balance of cells/modules, complexity and cost to create a safe and efficient system.

BMS Architectures

The designer’s selected architecture for the BMS determines the protection parameters.

In a centralized architecture, sense-balancing ICs connect by long wires between the cells and the slave boards. High-voltage fuses are used to reduce the risk of a short circuit under high-voltage conditions both in the module and between the cells in an accident. If a component is damaged in this centralized architecture, it can be replaced separately, making it a less expensive and simpler option.

In a modular architecture, all the components integrate into single modules. The distance between the cells and slave boards is much smaller. In this case, an accident is unlikely to cause a short circuit under high-voltage conditions. However, low-/medium-voltage fuses can be considered to protect against component failure and contamination on the BMS board at a lower cost. Two types of failure must be taken into account: short circuits and overload conditions. The small form factor is important, especially when hybrid space is shared with a combustion engine. However, if one component fails, the entire module has to be replaced at a higher cost.

Figure 1. A battery management system requires protection from threats such as overcurrents, surges and ESD. Points for circuit protection include fuses (1), TVS diodes (3, 5), TVS diode arrays (4, 6) and high-voltage fuses (7).

Figure 1. A battery management system requires protection from threats such as overcurrents, surges and ESD. Points for circuit protection include fuses (1), TVS diodes (3, 5), TVS diode arrays (4, 6) and high-voltage fuses (7).

Protecting the BMS

BMS circuit protection is critical for both in safety and reliability. Having robust protection throughout the system is essential. Because of the sensing lines at each cell, there is the potential for a short circuit in any cell. The cell monitor block or direct line must also be fused to avoid overcurrent damage. Protection locations for BMS in electric vehicles include:

- ICs used in cell monitoring to protect against overvoltage – TVS diodes

- Communication lines between units to protect against ESD – TVS diode arrays

- Battery IC protection in case of voltage transients – High-voltage TVS diodes

- Microcontrollers – TVS diode arrays

- Final protection barrier – High-voltage and high-current fuse in series with the main switch

- Other applications (e.g., inverters, DC/DC converters – high-voltage TVS diodes)

Application and Environment Define the Solution

Compared to stationary fuse and battery applications that are inherently vibration-free, cars are a very different environment in which the mass of the fuse matters. Battery voltages have been increased since the first generations of hybrid and electric cars. This requires the fuse to be larger in physical mass. The addition of vibration, inertia and momentum creates a mechanical as well as an electrical design challenge. Vehicle designers need to be confident that every component performs at or exceeds specified levels. Automotive design engineers should expect to work with a partner who is willing to customize testing to their product level. Suppliers need to offer expertise in simulation testing along many different metrics to serve the automotive market and show certification in automotive-grade standards.

Design engineers are cognizant of the critical safety role of battery management systems in electric vehicle development. Testing is being moved from a final-phase step to early in the process. Partnering with suppliers who embrace the application parameter requirements, provide innovative testing solutions and support advanced problem solving with the customer provides the expected level of service. In this ever-evolving market, teamwork between customer and supplier results in collaborative expertise.

Regulations and end-user demands will rule the market of hybrid and pure electric vehicles. Safe, efficient and affordable vehicles of the future depend on designers applying circuit protection solutions that are able to satisfy those requirements.

For more information on Littelfuse Battery Management Systems with detailed circuit diagrams and guides, click here for a free copy of our Automotive Electronics Applications Guide.

Get an overview of the future of automotive electronic systems from Automotive Electronics Business Vice President and General Manager Eyal Altman in this video from Littelfuse. Click here.

More videos available from Littelfuse:

Littelfuse PTCs: ASMDC, FemtoA SMD and PicoA SMB

Littelfuse DST Series Schottsky Diodes Rectifier: High temperature, low leakage and lower VF

Littelfuse SPIIxx Series Discrete Unidirectional TVS Diode