Protean Electric, a developer of in-wheel electric drive systems, has generated $70 million in funding from an equity financing round. The company will use the new money to ramp up production in China of its PD18 product line.

Protean is setting up a manufacturing site in Tianjin, China, and plans to form a manufacturing joint venture with Chinese auto parts manufacturer Zhejiang VIE to produce other in-wheel motor products.

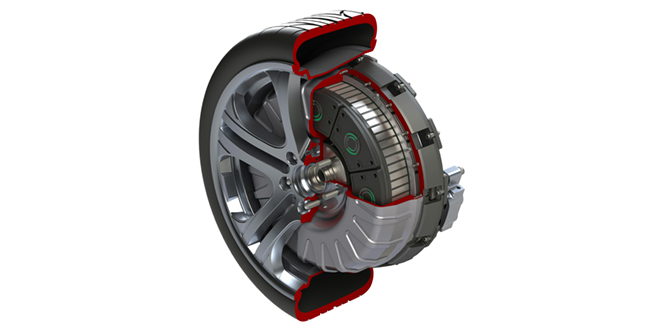

According to Protean, its in-wheel motors, which are suitable for both passenger and commercial vehicles, can boost an electrified vehicle’s energy efficiency by up to 15 percent compared to a centralized motor.

“This funding accelerates the adoption of our innovative technology in the booming electric vehicle market in China,” says Protean CEO KY Chan.

“VIE’s strong China customer base, its broad range of chassis products, and its manufacturing prowess are highly complementary to Protean’s technology leadership,” said Leal Jiang Chen, President of VIE Group.

“Protean has developed a next-generation power train with greater potential than anything I have seen in my 30 years in the automotive industry” says Frank Chao Lyu, Chairman of Tianjin THSG.

Source: Protean Electric