Volkswagen Group-owned battery manufacturer PowerCo SE plans to introduce a new battery cell manufacturing method in its plants in Europe and North America.

PowerCo predicts that its new Dry Coating procedure may save 30% of energy consumption and 15% of floor area, saving hundreds of millions of euros annually.

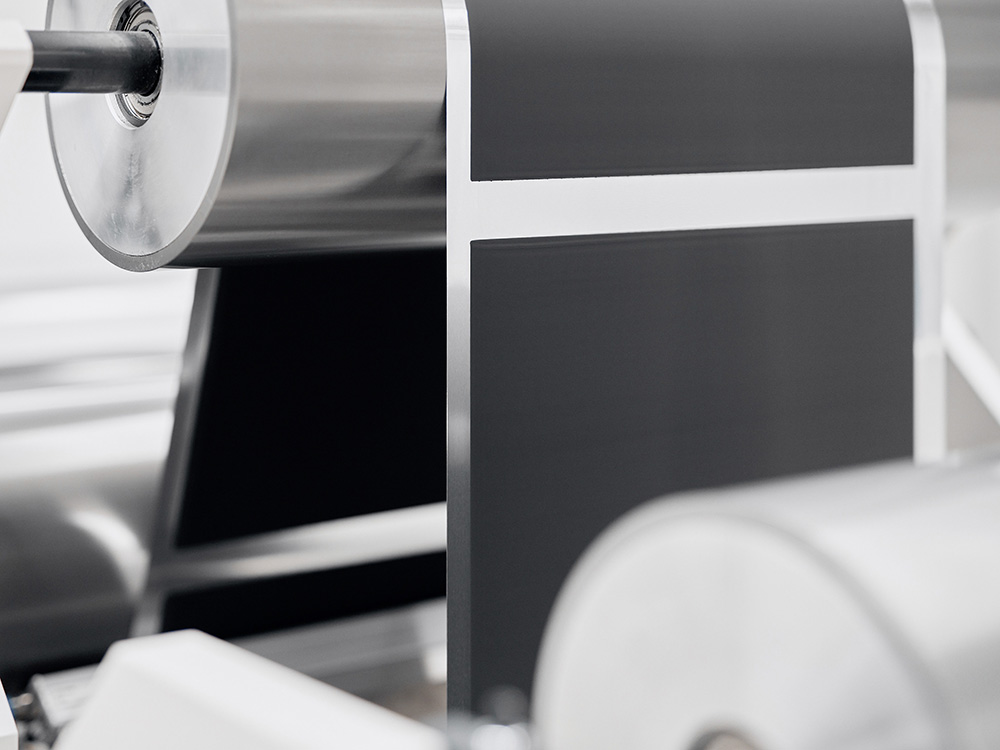

According to a Joint Development Agreement, PowerCo SE will develop and industrialize the Dry Coating method alongside German printing machine specialist Koenig & Bauer. They will develop an industrial roller press for powder coating electrodes. The Dry Coating method eliminates the most energy-intensive component of cell manufacture—wet-coating and drying electrodes—as well as chemical solvents.

The procedure allows manufacturers to calender the powdery basic materials directly onto the foil, similar to a printing procedure. This removes two of four process steps in electrode manufacturing. The powder coating can be applied onto the foil in a thin layer. This ensures energy density and a long life cycle while improving the battery’s fast-charging ability, the company said.

“What the solid-state cell is to the product, Dry Coating is to production,” said Frank Blome, CEO of PowerCo SE. “If scaled successfully, it will give us a unique position on the market and definite competitive advantages.”

Source: Volkswagen