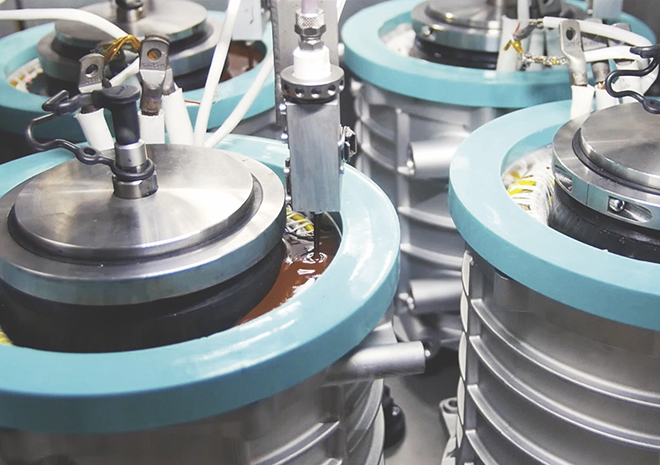

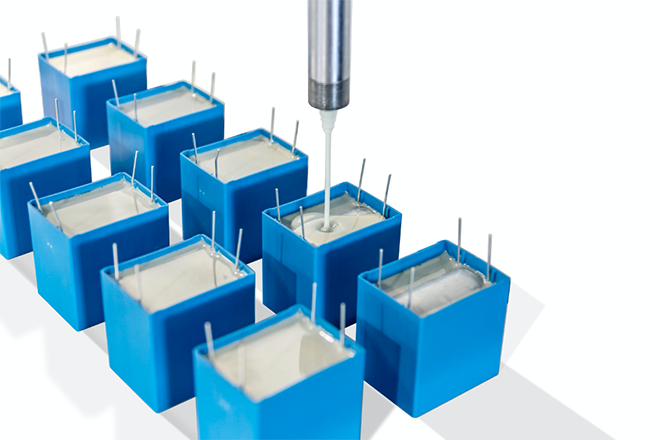

Established in the early 1980s, Demak Group develops new technologies for the dispensing of resins, by producing equipment for the degassing, meter-mixing, and dosing of epoxy, polyurethane, silicone resins, and many others. In addition to formulating and producing chemicals, it can also supply customers with suitable resins for their processes and productions, thanks to its sister company S.E. Special Engines Srl.

Due to the continuous miniaturization of devices and the introduction of more and more electronics into everyday life, resin applications are increasing in many sectors, including the automotive world. The role of resins is to improve the reliability and performances of electromechanical elements, and in this specific field, insulation is absolutely necessary to grant very long component durability.

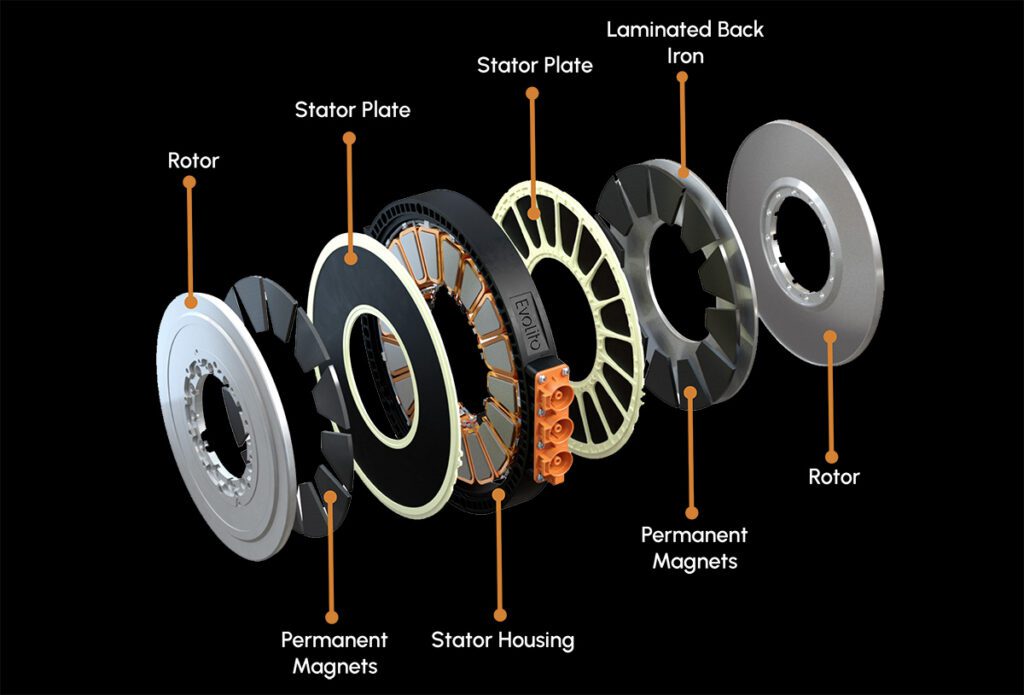

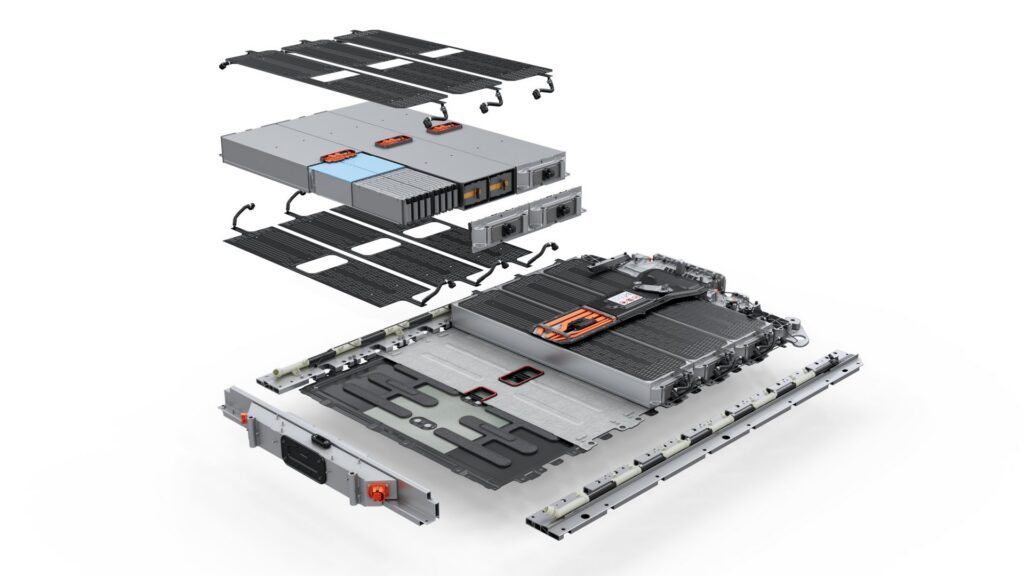

The need for encapsulating electronic parts is growing fast, especially because of the development of electric and hybrid technologies, which represent a very challenging area as the elements have to fulfill extremely high engineering and quality standards.

The market is requiring components working at very high temperatures, with maximum levels of protection and many restrictions on the use of volatile substances. As electromechanical component quality requirements are getting higher, the quality of resin systems and resin dispensing machines must be increased as well. This has led manufacturers to consider replacing polyester paints and resins with two-component epoxy resins.

LET US INTRODUCE YOU TO THE NEW GENERATION OF EPOXY RESINS