South Korean chemical manufacturer POSCO Future M is introducing new anode and cathode material technologies for EVs and adjusting its supply chain strategy for EV components.

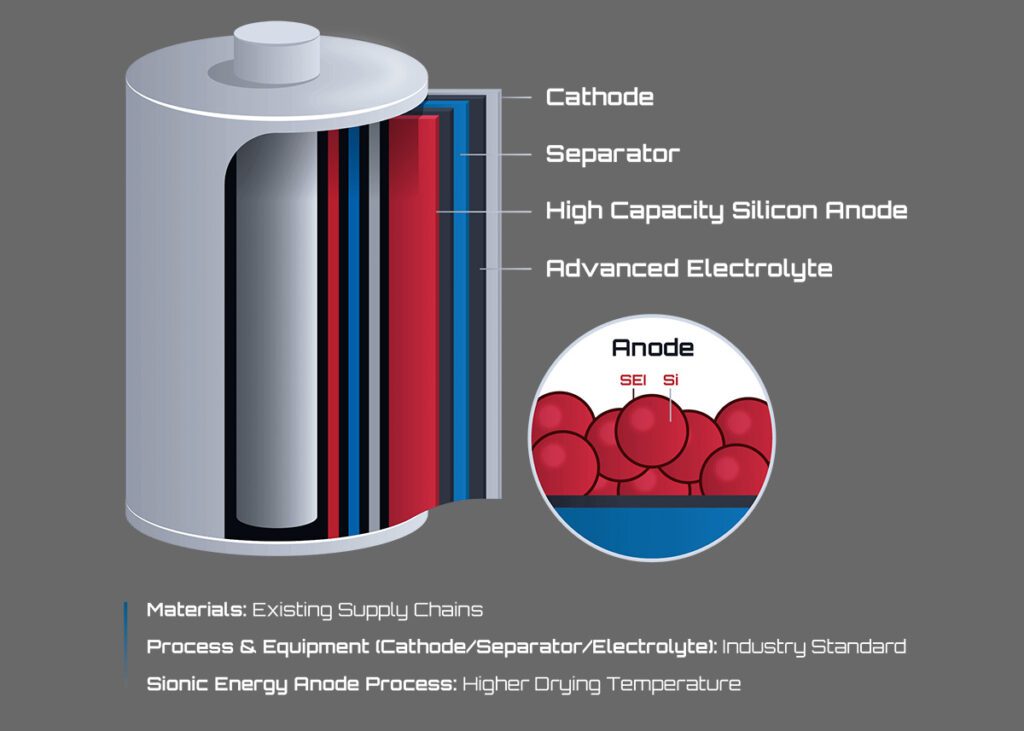

The company has developed a nickel-nickel single-crystal cathode material that maximizes energy density by increasing the nickel content to over 95%. POSCO Future M plans to secure mass production technology for this product by 2026. The company has been operating a demonstration plant since last May to produce silicon anode material that it says can increase storage capacity by about five times compared to graphite anode materials, and plans to begin mass production in 2027.

POSCO has also developed a low-expansion natural graphite cathode material to support faster EV charging. It has improved the material structure from plate-like to isotropic to increase the movement speed of lithium ions and reduce volume expansion. Starting in 2027, the company plans to start mass-producing a product that it says can reduce charging time by 30% compared to its existing material.

Lithium manganese-rich (LMR) cathode materials contain less nickel and cobalt than lithium-nickel-manganese-cobalt materials. When recycling is taken into account, the price is similar to LFP, but energy density can be increased by up to 30%, POSCO said.

The company also plans to introduce high-voltage mid-nickel (Mid-Ni) single-crystal cathodes that can be used in mid-priced EVs, lowering the nickel content to approximately 60% but applying high voltage to increase the energy density.

POSCO Future M is investing in its supply chain, inclduing its direct lithium extraction method, new nickel wet refining process technology and dry recycling technology. It has expanded its investment in lithium salt lakes in Argentina, lithium mines in Australia, nickel smelting operations in Indonesia and graphite mines in Africa, and plans to secure further resources.

POSCO International is also working on building a supply chain for core EV components such as drive motor cores and graphite. It has set a goal to build its global annual production system to 7.5 million units and reach a 10% market share by 2030. It plans to complete a plant in Brzeg, Poland this year.

Source: POSCO Chemical