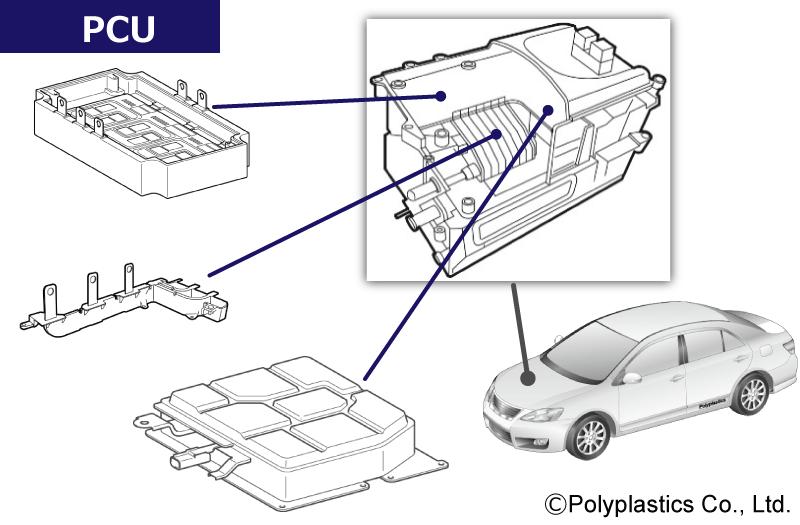

Japanese engineering plastics manufacturer Polyplastics has launched a new glass-filled polyphenylene sulfide (PPS) grade that meets the requirements for metal insert molding, particularly for EV busbars.

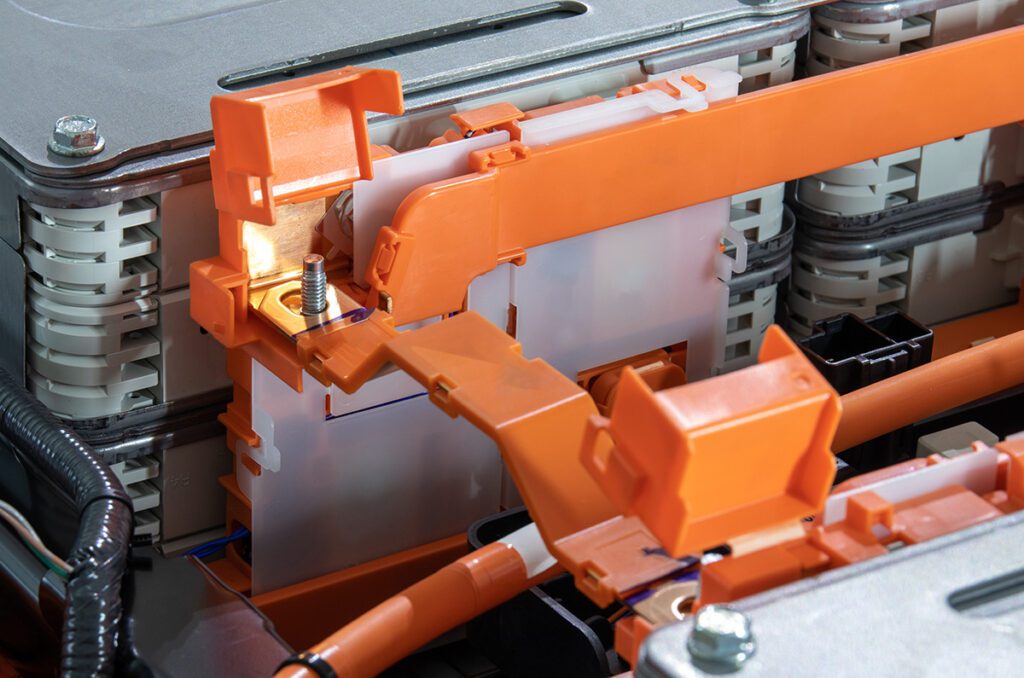

The DURAFIDE PPS 1140HS6 is designed to limit molding imperfections and enhance performance without the need for impact modifiers in EV busbar applications. Insert-molded EV components are typically made from metal that conducts electric power and PPS resin that functions as a coating for insulation. Repeated heating and cooling can result in cracking that leads to insulation failure, particularly in the critical parts of EVs that conduct high-voltage currents.

Adding impact modifiers to PPS tends to reduce material strength and allow gas and mold deposits to emerge during molding, according to the company, and makes PPS difficult to recycle. The DURAFIDE PPS 1140HS6 can be collected without being separated from other PPS components during recycling.

“The newly developed DURAFIDE 1140HS6 PPS resin offers better flowability during injection molding than standard materials. This makes it an ideal choice for molding both thin-wall and large products,” the company said.

Source: Polyplastics