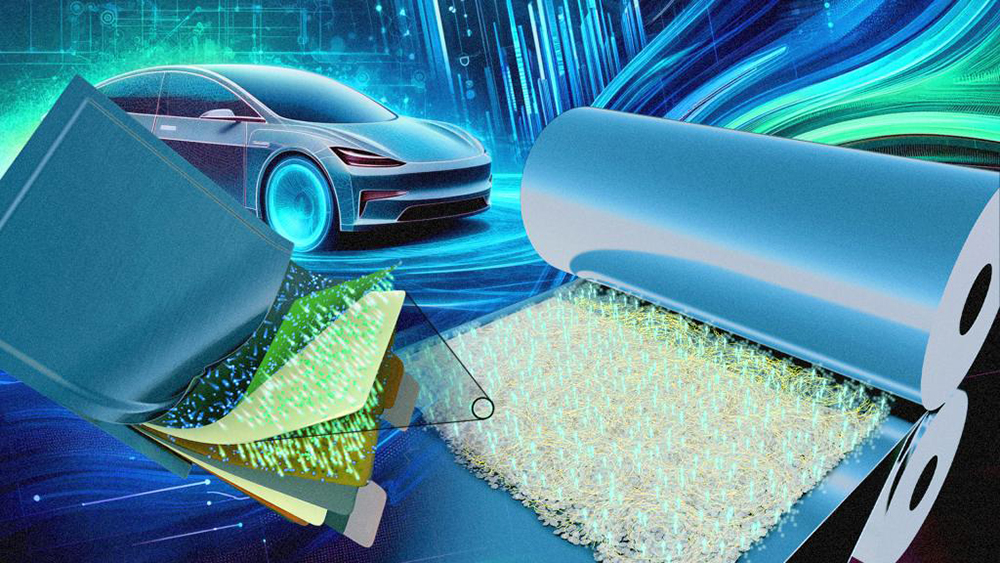

Researchers at the Department of Energy’s Oak Ridge National Laboratory (ORNL) have made a thin, flexible, solid-state electrolyte that may double energy storage for EVs.

Using a polymer to make a strong yet springy thin film, the scientists are developing flexible, durable sheets of solid-state electrolytes that may allow scalable production of solid-state batteries that have electrodes with higher energy density. By separating negative and positive electrodes, they would prevent dangerous electrical shorts while providing high-conduction paths for ion movement.

Current solid-state electrolytes use a plastic polymer that conducts ions, but their conductivity is much lower than that of liquid electrolytes, and they often incorporate liquid electrolytes to improve performance. However, sulfide solid-state electrolyte has ionic conductivity comparable to that of the liquid electrolyte currently used in lithium-ion batteries.

The researchers discovered that the polymer binder’s molecular weight is key for creating durable solid-state-electrolyte films. Films made with lightweight binders, which have shorter polymer chains, lack the strength to stay in contact with the electrolytic material. By contrast, films made with heavier binders, which have longer polymer chains, have greater structural integrity.

The work, published in ACS Energy Letters, improved on prior ORNL work by optimizing the polymer binder for use with sulfide solid-state electrolytes. The goal of the study was to find the “Goldilocks” spot—a film thickness just right for supporting both ion conduction and structural strength.

The team will build a device that can integrate a thin film into next-generation negative and positive electrodes to test it under practical battery conditions, and then partner with other researchers to develop and test the film in other devices.

“Our achievement could at least double energy storage to 500 watt-hours per kilogram,” said ORNL researcher Guang Yang. “The major motivation to develop solid-state electrolyte membranes that are 30 micrometers or thinner was to pack more energy into lithium-ion batteries so your electric vehicles, laptops and cell phones can run much longer before needing to recharge.”

Source: Oak Ridge National Laboratory