Researchers at the US Department of Energy’s National Renewable Energy Laboratory (NREL) have demonstrated a physics-informed neural network (PINN) model that they say can predict battery health nearly 1,000 times faster than traditional models.

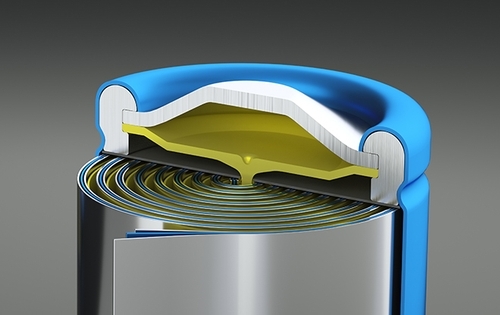

NREL’s PINN replaces the traditional, resource-intensive battery physics model with an approach based on AI that mimics the interconnected neurons of our brains to analyze nonlinear, complex datasets. This deep learning process can quantify physical degradation mechanisms and pave the way for more efficient, scalable approaches to manage battery aging.

“Instead of a physics model, we proposed a PINN surrogate model to separate out a battery’s internal properties from its output voltage,” said NREL Computational Science Researcher Malik Hassanaly, who collaborated with the battery research team. “This approach drastically reduces the computational time and resources required, allowing researchers to quickly diagnose battery degradation and provide real-time feedback on battery health.”

The two-part study published in the Journal of Energy Storage demonstrates how researchers trained and tested the PINN surrogate using conventional SPM and P2D models. This allowed them to train the PINN surrogate on a range of internal battery properties, offering insights into changes that occur during battery aging to help estimate how long a battery might last in different settings.

PINNs are designed to understand and follow physical laws by embedding them directly into the model’s training procedure, enabling it to predict battery parameters with a level of scientific rigor previously achievable only by complex, time-intensive models. Techniques typically constrained by high resource requirements can now be applied on a broad scale.

The NREL researchers are working to transition the PINN surrogate from controlled simulations to real-work data validation, using batteries cycled within NREL’s laboratories. Future research will focus on refining the model to handle highly dimensional problems, allowing it to predict a broader array of internal battery parameters with increased precision. This means creating models that can respond to diverse current loads and scale effectively to future battery designs and usage patterns.

“This approach unlocks new capabilities in battery diagnostics, paving the way for onboard diagnostics of batteries in use,” said Kandler Smith, who leads electrochemical modeling and data science research at NREL. “This means that batteries of the future may include systems to extend their useful life by identifying degradation signals and adapting fast-charge limits with age.”

Source: NREL