Researchers from the Fraunhofer Institute for Chemical Technology and the Karlsruhe Institute of Technology have developed a new method for cooling electric motors, which could help reduce the weight of EVs. With the new cooling method, motors can be housed in lighter-weight polymer materials, and they also benefit from increased efficiency and power density.

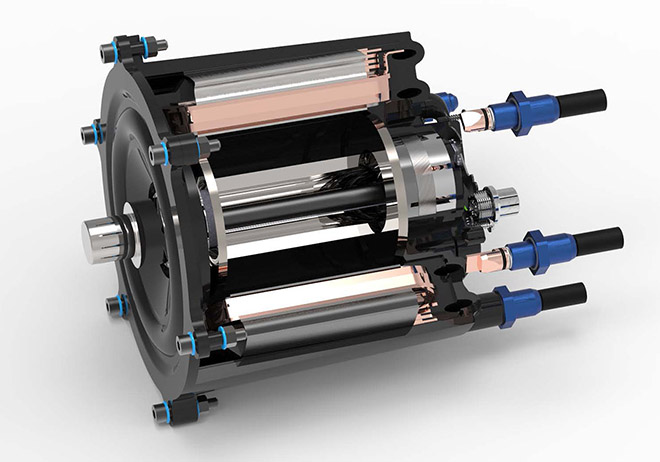

The new method involves directly cooling the stator and rotor, the two components of an electric motor. Currently, the typical cooling method is to conduct heat from the stator through the motor’s metal housing into a cooling sleeve filled with cold water. In the new method, the researchers replaced the conventional round wires in the stator with rectangular flat wire, creating space for an integrated cooling channel.

“In this optimized design, the heat losses can be dissipated through the cooling channel inside the stator, eliminating the need to transport the heat through the metal housing to an exterior cooling sleeve,” said researcher Robert Maertens. “In fact, you no longer need a cooling sleeve at all in this concept. It offers other benefits, too, including lower thermal inertia and higher continuous output from the motor.”

Coolant circuit in the stator

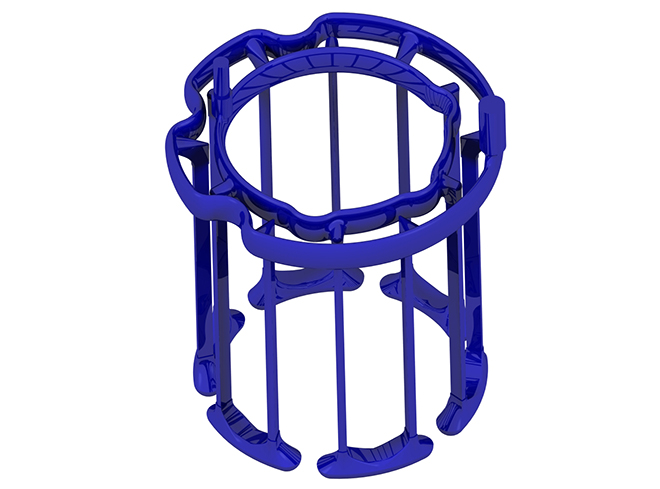

The direct-cooling solution also allowed the researchers to replace the metal housing of the motor with lighter-weight polymer materials.

“Polymer housings are lightweight and easier to produce than aluminum housings,” said Maertens. “They also lend themselves to complex geometries without requiring post-processing, so we made some real savings on overall weight and cost.”

So far, the new design has only been validated through simulation, in which the researchers found it can dissipate 80 percent of the expected heat from the electric motor. The next step is to assemble the motor and validate its performance in real-world operation.