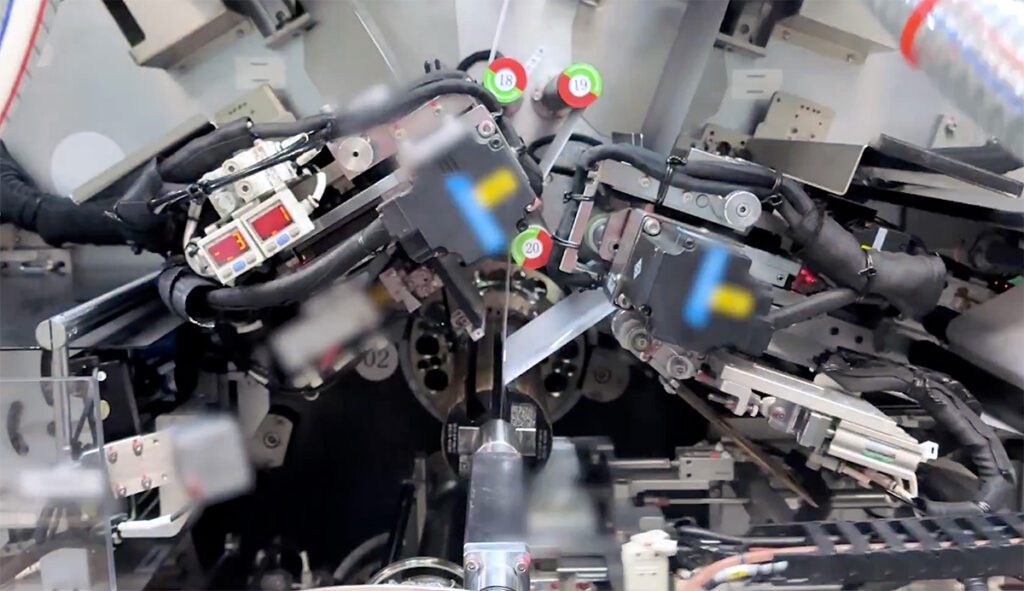

Measurement technology provider NDC Technologies has announced its next generation of sensors for lithium-ion battery cell manufacturers. NDC claims that its four new devices will allow manufacturers to produce more consistent, higher-quality electrode components.

The new Photon Sensor measures the weight of coatings applied to anode/cathode copper and aluminum foil substrates. According to NDC, the measurement accuracy is 10 times better for the cathode and 4 times better for the anode than traditional Beta (nuclear) sensors.

The new Micro-Caliper Thickness Sensor provides thickness measurements for press line calendering applications. The system provides accuracy better than 0.3 microns and can report thickness variations less than 1 mm in width.

The new Web Surface Inspection System is a camera-based defect inspection tool. It can detect and classify optical defects of the coating on calender/press lines across a range of materials.

Finally, the new Beta LaserMike LaserSpeed Pro is a non-contact length and speed gauge designed to monitor the speed of battery coating and press lines. The laser-based gauge offers accuracy better than +/-0.03% and provides connectivity, communication, and control capabilities.

Source: NDC Technologies