Sponsored by Momentive Performance Materials

With the onset of ever-shrinking electronic components and systems with more functionality and power in the automotive industry, the demand for thermal management materials, such as gap fillers, have rapidly increased over the past several years. Together, with the continuing trend of reducing device dimensions, this has led to a dramatic increase in thermal issues within electronic circuits.

Momentive has been supplying thermal gap fillers to the automotive industry for more than a decade and is continually testing the effectiveness of thermal management materials in automotive applications. Momentive recently conducted a study, based on a major United States OEM test standard, to gauge the ability of its thermal gap fillers to remain where they are applied; as well as to help dissipate heat from electronic components in the high heat and extreme vibration conditions found in automobiles.

SilCool™ Thermal Gap Fillers vs. Pre-cured Gels

Momentive’s SilCool™ thermal gap fillers are thixotropic thermally conductive silicone materials that are used to dissipate heat from electronic devices. The soft nature of these materials enables stress relief during thermal cycling and vibration.

Silicone pre-cured gels are single-component tacky, highly conformable gels. They are known to provide good thermal stability and reliable performance. They are generally used for filling variable gaps between multiple components.

The test

The goal of the test was to evaluate select gap fillers and a pre-cured gel for their ability to withstand random vibrations at high and low temperatures.

Preparing the silicone for testing

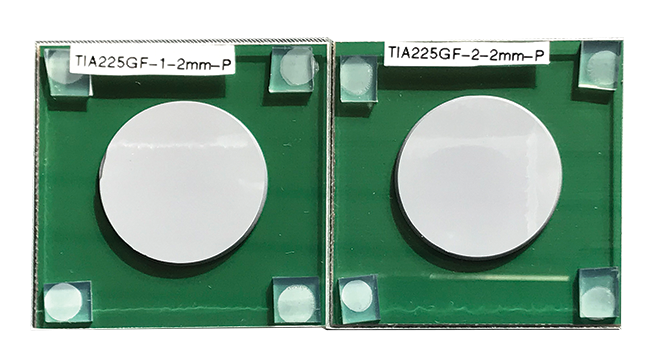

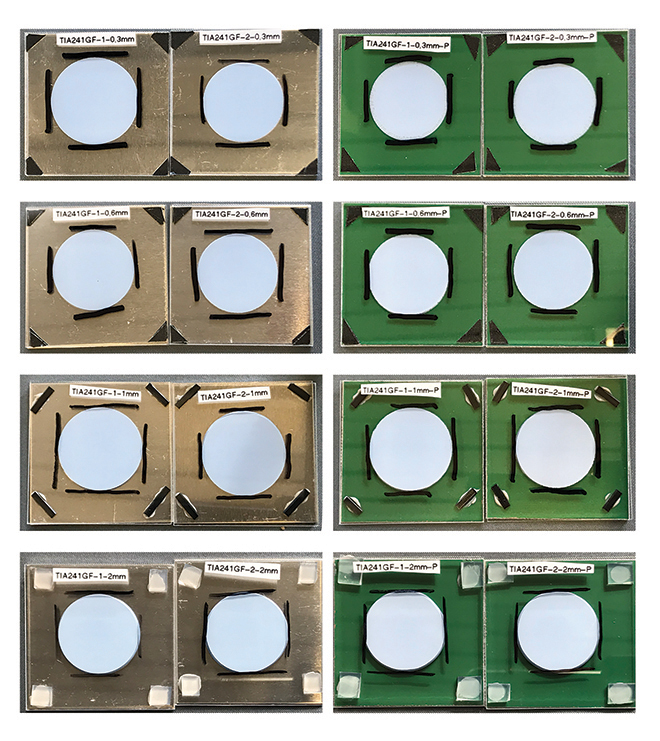

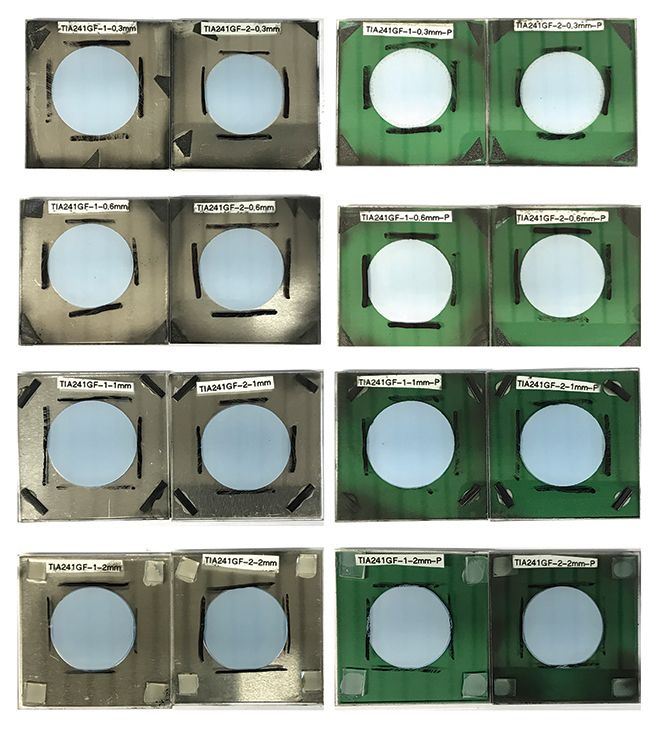

Three different Momentive thermal gap fillers, including SilCool™ TIA225GF, SilCool™ TIA241GF and SilCool™ TIA282GF thermal gap fillers, as well as one pre-cured gel from a competitor were used in this test.

| Material | Thermal Conductivity | Cure Type | Appearance |

|---|---|---|---|

| SilCool TIA225GF | 2.5 W/mK | RT Cure / 30 mins at 70°C | Gray |

| SilCool TIA241GF | 4.1 W/mK | RT Cure / 30 mins at 70°C | Light Blue |

| SilCool TIA282GF | 8 W/mK | RT Cure / 60 mins at 70°C | Light Pink |

| Competitor P | 3.5 W/mK | Pre-cured | Pink |

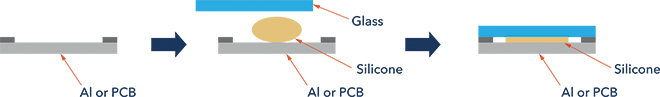

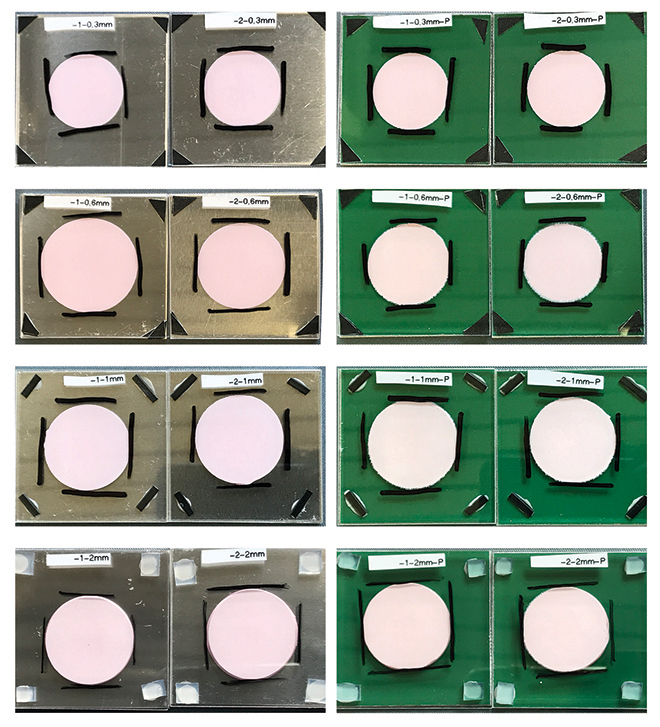

Momentive prepared the liquid dispensed gap fillers by applying different thicknesses, including 0.3 mm, 0.6 mm, 1 mm and 2 mm, to a mating surface of either aluminum or PCB and covering them with glass. The materials were then cured according to their technical data sheets. The competitive, pre-cured gel was applied to the same substrates and covered with glass following manufacturer instructions. The position of each sample was then marked on the glass.

Test Methods

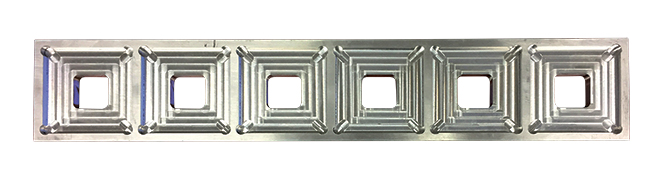

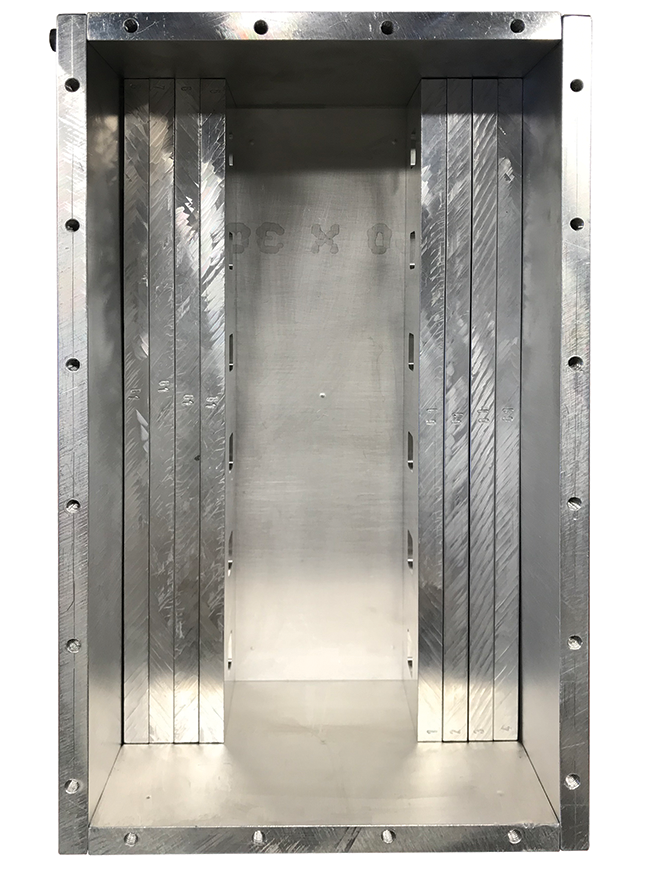

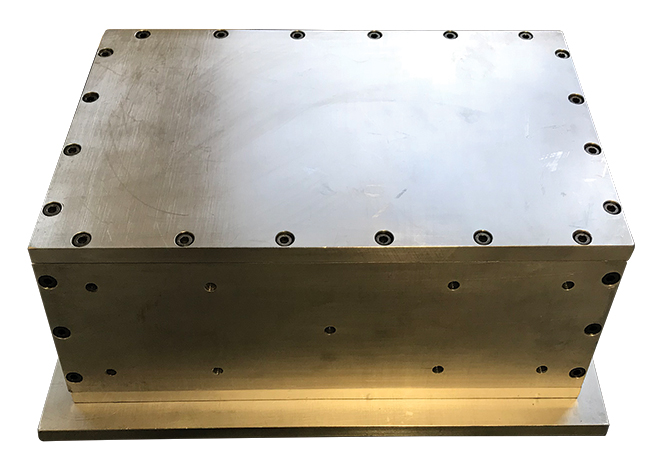

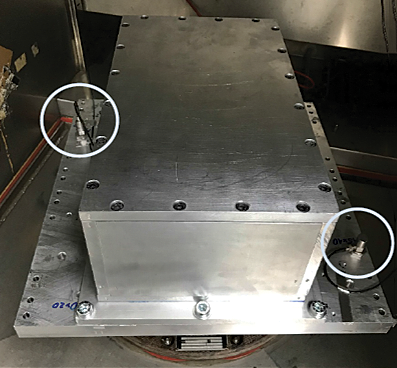

The prepared test samples were stacked and placed into metal frame holders. The holders were then placed in a vibration unit that provided the required vibration conditions and thermal cycle profile specified in a major US OEM manufacturer’s standards.

Vibration testing was performed according to sprung mass conditions (truck) at 2 g for 36 hours on each axis or 108 hours total. Samples were subjected to prescribed vibration patterns along the x, y and z axis. Acceleration sensors were used to measure and record data. Samples were tested in a precisely controlled climatic chamber. Temperatures were adjusted according to the major US OEM manufacturer’s standard thermal cycle profile, ranging from -40°C to +90°C. Once the test was complete, the samples were checked to see if the silicones stayed in position.

Results of the Study

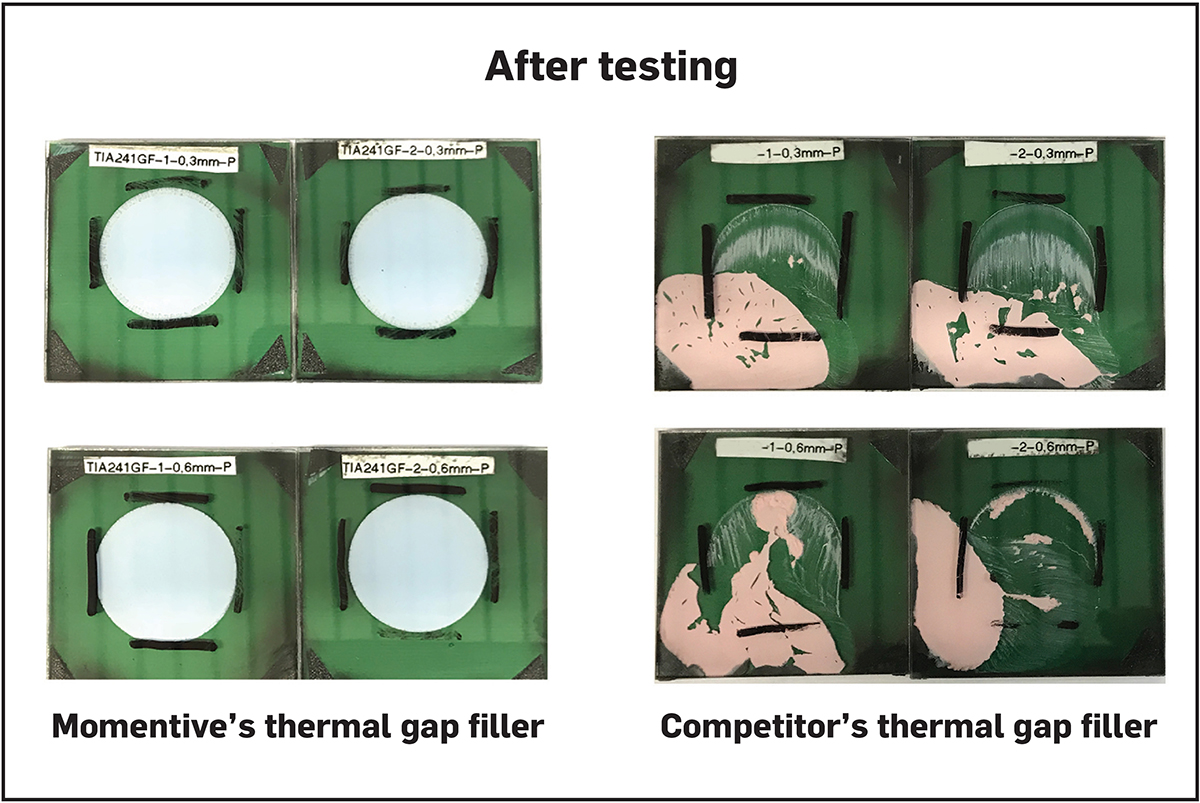

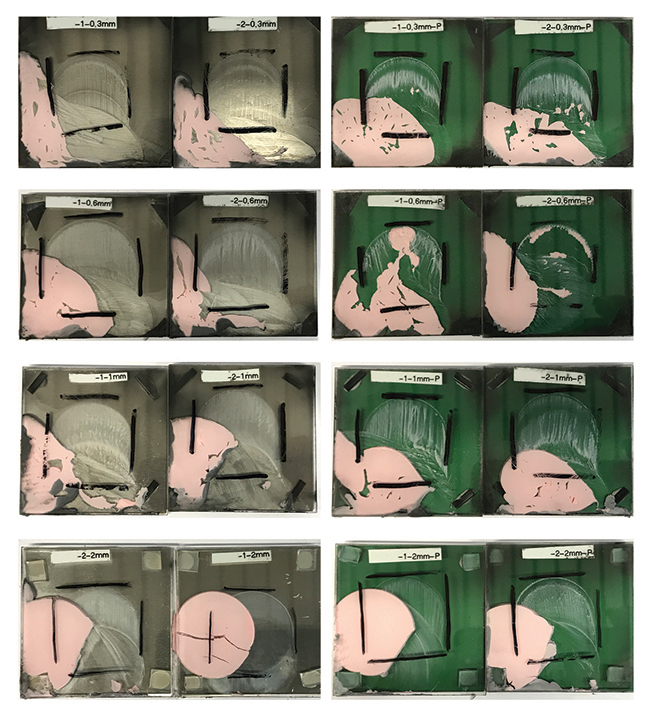

In this study Momentive’s two-part thermal gap fillers demonstrated a better ability to meet the OEMs hot vibration standards than the competitive one-part, pre-cured gel material. The Momentive samples showed no shifting, no cracking and no slipping, making them an excellent choice for use in automotive electronic applications.

Conversely, the competitive material showed significant shifting and

slippage after the hot vibration testing and was therefore not able to

demonstrate its ability to meet this particular standard for use in automotive

applications.

Conclusions

Keeping electronic components cool has become more critical as systems shrink in size and increase in complexity, making it important that thermal management materials remain in place to assist in heat removal.

Momentive’s two-part thermal gap fillers have shown the ability to excel at heat dissipation and to remain where they are applied, even in automotive applications where high vibration and high heat are often found. Unlike the pre-cured gel material that was tested, Momentive’s two-part gap fillers were able to demonstrate the ability to more fully crosslink with the substrate as the silicone cures to provide much better material anchoring.

Want to learn more?

Contact us today to learn more about Momentive and the various thermal management solutions it has to offer. Our team of highly skilled professionals will work with you to help find the best solution for your automotive application.

SilCool is a trademark of Momentive Performance Materials Inc.