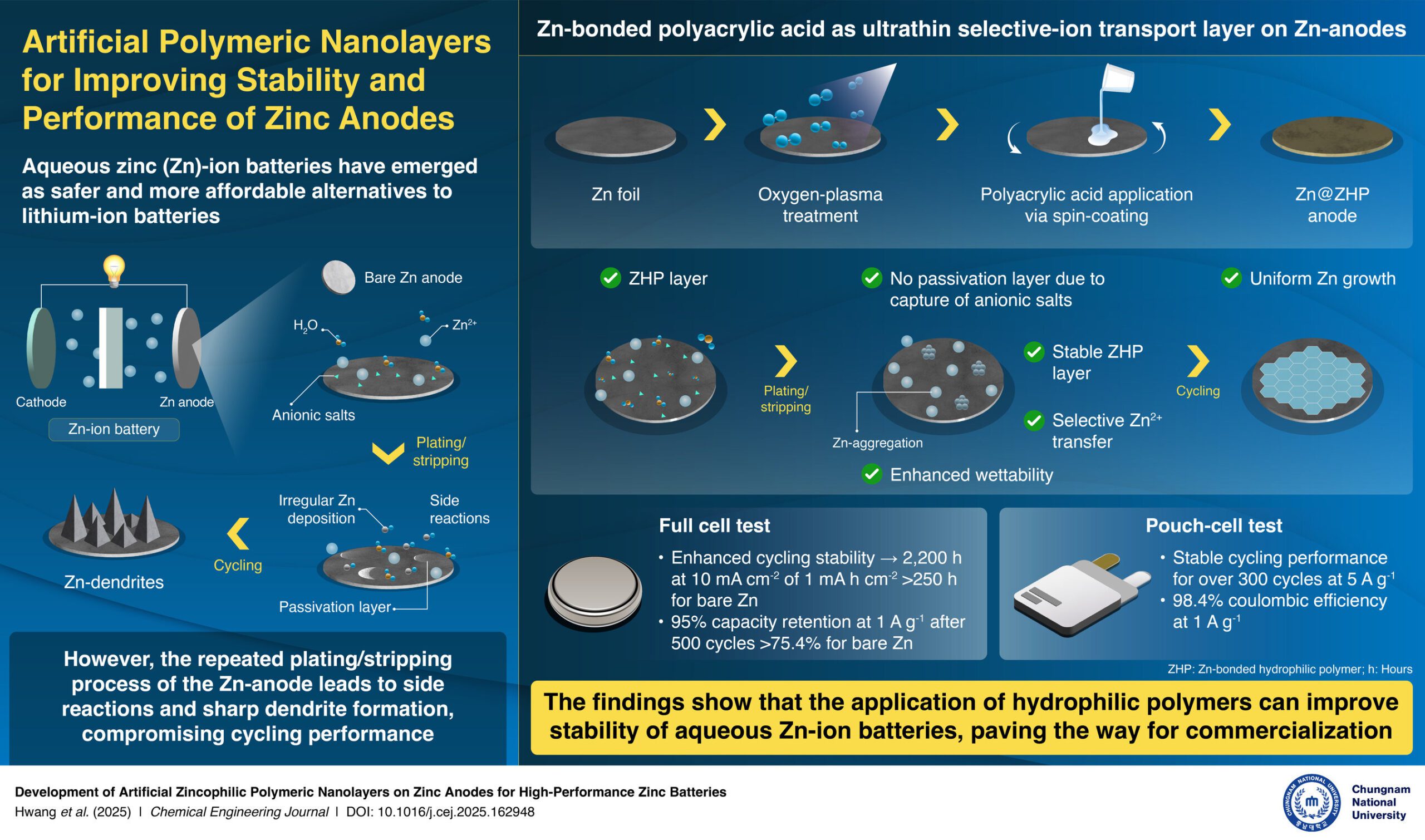

Researchers at Chungnam National University in South Korea have developed a new zinc-bonded polyacrylic acid (ZHP) layer that prevents dendrite growth and stabilizes the anode in zinc-ion batteries.

Aqueous zinc-ion batteries are gaining attention as a safer and more affordable alternative to lithium-ion batteries. However, previous protective coatings developed to prevent side reactions and sharp dendrite formation during charging and discharging were often too thick or difficult to manufacture, limiting their real-world use.

The research team, led by Associate Professor Woo-Jin Song from the Department of Organic Materials Engineering at Chungnam National University, has designed a new ultra-thin selective-ion transport layer (SITL) that is effective and easy to produce.

The SITL is based on polyacrylic acid (PAA), which can prevent direct contact between the zinc anode and water-based electrolyte, inhibiting corrosion. Its hydrophilicity also improves ion transfer between the electrolytes and the anode, promoting uniform distribution of zinc-ions and enhancing battery performance.

Bare PAA tends to dissolve in water-based electrolytes, reducing cycling performance. To prevent this, the researchers applied oxygen plasma treatment to zinc-anode, which enhanced adhesion between PAA the layer and the anode surface. The PAA was deposited on the treated zinc-anode using the cost-effective and scalable spin-coating technique, resulting in a nanoscale PAA coating. The PAA-coated anode was then heated on a hot plate, forming the zinc-bonded PAA ZHP layer.

In full cells, the ZHP coated zinc anode retained 95% of its capacity after 500 cycles. In pouch cells, the anode demonstrated stable cycling for over 300 cycles.

“In this study, we developed a nanoscale zinc-bonded polyacrylic acid (Zn–PAA) protective layer for zinc anodes via oxygen plasma treatment,” said Dr. Song. “Unlike conventional thick and complex coatings, our approach offers a simpler fabrication process and is scalable for large-area applications.”

Source: Chungnam National University