When it comes to finding a way to charge EVs more quickly, human ingenuity has come up with some pretty wide-ranging solutions, from battery-swapping to flow batteries that store energy in tanks of liquid electrolyte. The latest innovative idea comes from startup Tanktwo, and is called a String Battery.

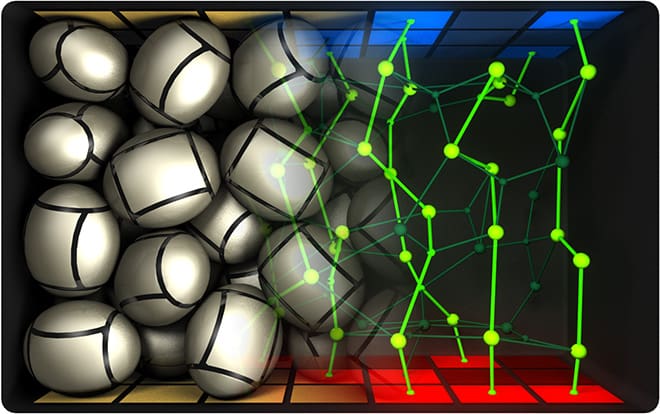

Tanktwo’s system replaces a vehicle’s battery pack with a container filled with several thousand “small and intelligent string cells.” A sort of vacuum-cleaner device sucks spent cells out of the tank and refills it with charged cells. Swapping all the string cells takes less than 3 minutes.

“The String Battery is built with regular lithium-ion cells that are made smart,” said Bert Holtappels, Tanktwo’s founder and CEO. “These String Cells utilize key principles from wireless networks, the internet, and mobile phone hardware design. Significant improvements in battery pack costs are the result.”

After watching the company’s promo video, we had a more than a few technical questions and some general concerns about the feasibility of the overall concept. Conveniently enough, the company seems to have answers to all of them.

This is thinking pretty far out of the box, but it does appear to be very well thought out. If these little things really perform as the company says they do, the whole crazy thing might just have a future.

For starters, it seems that the connections between cells would be very difficult to maintain in a vehicle that’s bouncing around the road. How do you keep the cells steady within the tank?

“Due to the unique geometry (ellipsoids with a specific semi-axis ratio) the random packing density is, within reason, as high as theoretically possible,” Holtappels told Charged. “High random packing density means little empty space, which leaves almost no opportunity for rattle. Think how a sand bag handles, vs. a bag of marbles. For less-than-full loads, we use a bladder system, not unlike used in ordinary expansion tanks.”

“The algorithms are dynamic and re-route on the fly, and in the theoretical worst-case scenario where we briefly loose 100% of all contacts, a small buffer capacitance provides propulsion power until string power delivery is restored.”

OK, how about energy density? How does the energy per unit volume and energy per unit mass of a String Cell system compare to that of a traditional battery pack?

“We meet or exceed the density of a traditional pack, other things being equal,” Holtappels told us. “The ellipsoid-shaped String Cells fill about 73% (max. 76%) of the available space, a little less if the String Battery container is small (due to wall-effects). At 73% fill ratio, it leaves 27% for cooling, a ratio which works out perfectly. We cool with air.”

“Also, because our String Batteries require no rigid frame, there are significant structural savings too, particularly in system weight. We supply certain engineering tools to our customers, which assist in dimensioning and design.”

Wouldn’t building the infrastructure be a huge challenge to overcome?

Unlike a flow battery (or a hydrogen fuel cell), Tanktwo’s battery could also be charged from the electrical grid, so a String Battery-equipped EV can function like a normal plug-in. You don’t have to swap the cells to recharge the vehicle – you can just do so when you need a fast charge. So, this system could gradually build momentum – there’s no chicken-and-egg problem.

Automakers have their own ideas about battery form factors. Getting any of them to implement an alternative system is going to be a hard sell (this was one of the issues that sank Better Place).

Tanktwo says it has a functional prototype, and is already in confidential talks with “the usual suspects.” One of the company’s most intriguing promises is that its system offers a lower price per kWh than traditional battery packs. If it can deliver on this, it just might pique the interest of one or more OEMs.

Battery-swapping seems like a complicated way to address a temporary problem – won’t battery advances make this sort of thing unnecessary in a few years?

In fact, while batteries’ ability to accept charge quickly is likely to increase, there may always be a physical limit to charging speed. Above a certain power level, components begin to get really hot. Tesla uses the highest charging rates with some of its Superchargers, up to 135 kW, and it still takes tens of minutes to recharge. It may never be possible to charge a Tesla-size battery in 3 minutes, at least not without much larger cables, so a good battery swapping solution could find a place in the market someday.

A Q&A page on Tanktwo’s web site contains much more information. Here are a few more answers that we found particularly interesting:

The Tanktwo batteries seem to have no polarity … no + or -. Is that correct? If yes, how can they produce electrical power?

The string battery contains multiple string cells, that in turn contain an electrochemical cell. The string battery maps the string cells and decides the best way of connecting them together. The electrochemical cell inside a string cell has polarity, positive and negative. The string cell has an internal processing unit that can connect the positive or negative terminal of the internal cell to any of the contacts on the string cell surface. The electrical power is produced by the internal cell, but the string cell routes the power to any of the outside contacts, according to the routing plan received from the string battery.

What is the battery output voltage?

This is actually a multifaceted question. The string cells inside the Tanktwo string battery form many serially connected individual battery circuits that have a variable amount of cells in them. The voltage of these circuits could, for example, vary from 50 V to 150 V. These voltages are then converted to a voltage level that is desirable for the vehicle’s power electronics. Thus, the answer, in short, is that the output voltage can theoretically be almost anything, but it typically ranges from 100 – 600 V.

I’m concerned with the efficiency of your system. In one battery all the cells should be as similar as possible, not mixed with cells that have different age, use history and what not.

This is very true for traditional battery packs because the cells are connected in a series, so each battery is basically only as strong as its weakest cell. In the Tanktwo string battery, the string cells can be combined in almost any configuration. When the string battery builds its circuits, it combines the string cells into groups based on their properties, keeping the strong cells and weak cells in their own groups. By doing this, any cell can always give its best possible output, and the strong cells are not limited by the weaker ones. This is the main reason why you can get more power and energy out of the Tanktwo string battery, compared to a traditional pack that has exactly the same nominal capacity.

What is the price of your battery per kWh?

The price of Tanktwo battery capacity always closely follows the cost of the battery chemistry, which for the foreseeable future is lithium-based. The additional cost of the battery pack comes mainly from the battery unit’s integrated electronics; which at the appropriate scale, is marginal. On the other hand, Tanktwo battery packs offers more kWh and more peak kWs for the same cell capacity, compared to traditional battery packs. For this reason, the price per kWh for a Tanktwo battery pack will always be lower than the price per kWh of traditional battery packs made with the same battery chemistry and capacity.

Do you already have something functional, or are you just selling hype and seeking for investments?

Tanktwo makes components that need to be integrated into consumer products. We have designed and implemented functional prototypes for evaluation by our potential customers. These prototypes have all the functionality needed for customers to determine if this technology is right for them. In the meantime, R&D for next generation products is ongoing as well. These products have higher power density and work faster, but they are fundamentally the same as what we have today. We are periodically opening investment rounds to scale up our operations and work with more customers.

Source: Tanktwo