Sponsored by Pyrophobic Systems Ltd.

By Dr. Sean Luo

Pyrophobic Systems Ltd. has developed and commercialized an innovative intumescent battery housing LithiumPrevent™ to mitigate the risk of fire and explosion and improve the safety in the operational use, storage, logistics, manufacturing and testing of lithium (ion) batteries.

Battery Fire Containment

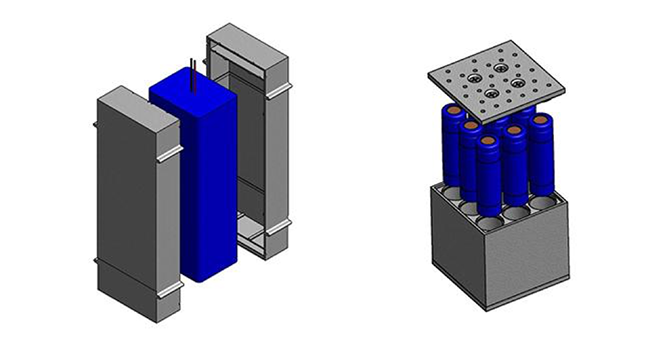

The LithiumPrevent™ battery housing is made from intumescent fire retardant polymer composites/nanocomposites (IFRPCs) with one or more through or blind holes as self-sealing venting outlet(s). This (these) venting outlets can relieve the surging internal pressure and quench a thermal runaway fire and/or explosion at the earliest stage of the event. When the IFRPC material made of the battery housing is exposed to the high heat and/or the fire generated in the thermal runaway event, the material will experience phase change to absorb the heat, intumesce to form porous, thermally insulative and inert char, as well as partial decomposition to absorb more heat and release fire inert gases to suppress the fire. This porous char around the event batteries mitigates the heat generation, contains the thermal runaway within a “dead cell” and insulates the heat from transmitting to the adjacent batteries to keep them cool to stop the chain reaction thermal runaway and keep other batteries in close proximity safe and sound.

Thermal Runaway Fire Protection

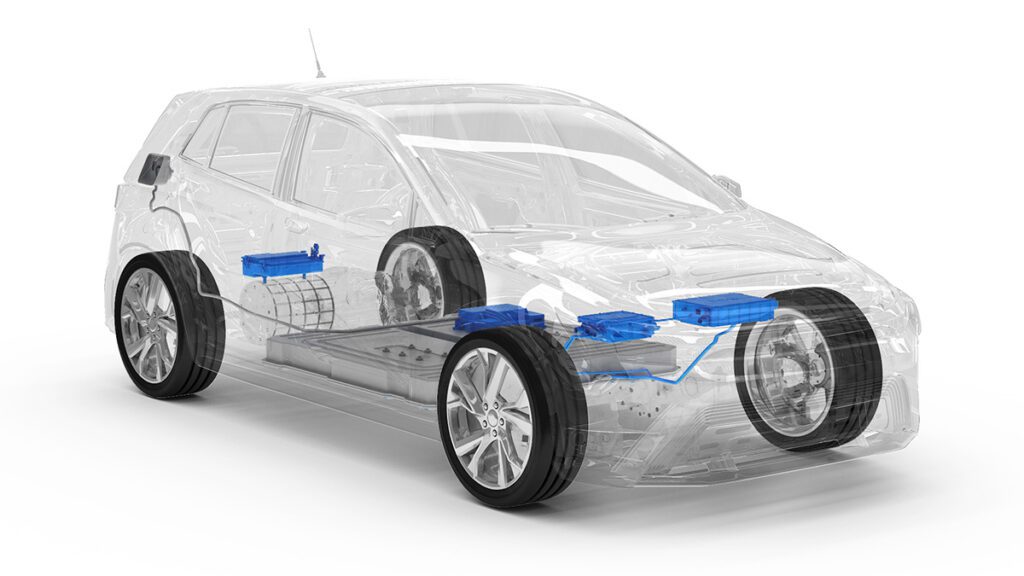

With the rise in popularity of electric vehicles, there is a rapidly growing concern with the inherent risks that come with this emerging technology. Electric vehicle owners can experience problems such as: faulty batteries, faulty chargers, faulty battery management systems, damage from road debris, damage in an accident causing an intense runaway event that spreads, liability to businesses and municipalities from runaway batteries used in commercial vehicles. LithiumPrevent™ technologies can be utilized in order to mitigate these inherent safety issues. A lot of testing conducted for different types of chemistry and cell sizes has proved that LithiumPrevent™ battery housing can limit the fast-moving cascading events to a single point or within a larger pack within a repairable level to protect property and life. Similar safety risks associated with lithium (ion) batteries exist in the applications of aerospace, energy storage, portable power packs, household and commercial batteries, and in the process of manufacturing, testing, logistics and storage. As LithiumPrevent™ technologies are used as the Class D containment packaging, everyone can have a much higher level of confidence in the entire logistics chain from manufacturer to the end users and in the operational uses of lithium (ion) batteries.

“Lithium batteries have become pervasive in our everyday life but with them come risks of catastrophic fire due to thermal runaway and/or overcharging,” says John Page, president of Pyrophobic Systems Ltd. “Our LithiumPrevent™ patented technologies mitigate thermal runaway preventing it from becoming catastrophic and contain it to a single point event.”

Meeting Industry Standards

This proprietary solution LithiumPrevent™ tested in NASA and FAA certified labs capable of containing lithium (ion) battery thermal runaway can help the users to meet the requirements of a variety of standards:

- UL 2580 Batteries for Use In Electric Vehicles

- UL 2054 Standard for Household and Commercial Batteries

- UL 2743 Standard for Portable Power Packs

- UL 9540A Test Method for Evaluating Thermal Runaway Fire Propagation in Battery Energy Storage Systems

- Federal Aviation Regulation 14 CFR Aeronautics and Space

- IEC 62133-2: 2017 Safety requirements for portable sealed secondary lithium cells, and for batteries made from them, for use in portable applications

- IEC 62281: 2019 Safety of primary and secondary lithium cells and batteries during transport

- UL 2595 General Requirements for Battery-Powered Appliances

- UL 1642 Standard for Lithium Batteries

Custom Engineered Solutions

The IFRPC materials used to make the LithiumPrevent™ battery housing can be processed like ordinary thermoplastics with plastic processing machinery. They can be injection moulded, extruded, thermoformed and calendered. Pyrophobic Systems Ltd. can customize the design of the battery box based on the shape, size and chemistry of the batteries, as well as the required safety level to ensure maximum confidence in the systems including lithium (ion) batteries. Consider these 10 Lithium Prevent Pack Designs when developing your solution. And the LithiumPrevent™ battery housing can be combined with various materials like metals, alloys, ceramics, polymers, cermets and other composites to provide desirable properties: mechanical strength, thermal management and electrical conductivity to meet customer needs.

Find out how Pyrophobic Systems Ltd. can help you engineer a better solution to your firestop challenges: https://pyrophobic.com/contact/