Sponsored by Nordson Sealant Equipment

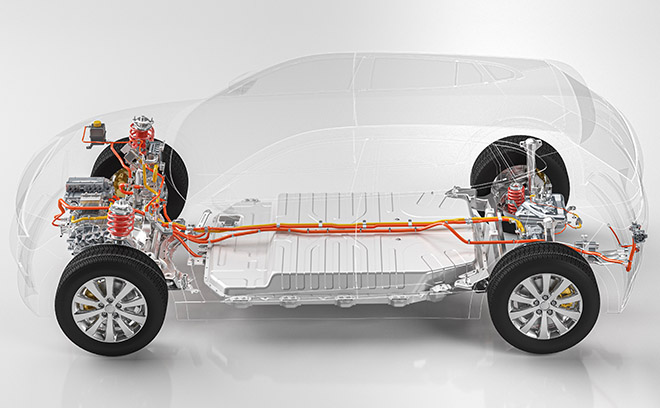

Nordson Sealant Equipment is identified as one of the leading precision dispensing manufacturers in the industry. We partner with most of the top 10 EV battery manufacturers to help build more than one million electric vehicles on the road today. While Nordson may know a thing or two about EV battery manufacturing we do want to inform OEMs and automotive manufacturers about the threats that could impact the production process of a battery pack assembly. Today we partner with our engineers to share a story that could be replicated throughout other factories around the world.

Customers often come to Nordson with a scenario, “We need to get this material onto a part as fast as possible, but it has to be accurate; what could Nordson do for us?” As simple as that question sounds our team of experts work behind the scenes to uncover what other factors could impact this process. The biggest challenge our engineers see is the affect certain materials can have on the wear life of dispensing equipment.

Put your material to the test

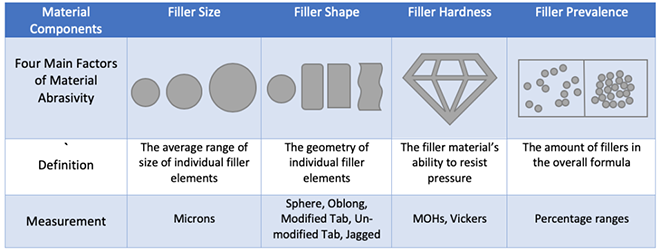

In Wixom, MI United States, Nordson Sealant Equipment offers customers the ability to bring in their materials i.e., adhesives and sealants, to the Material Testing Labs to be tested directly within industry leading equipment. Nordson engineers take a scientific approach to identify the material fillers, shape, size and even hardness to identify the best equipment to fit a customer’s needs. We have the flexibility to modify our equipment for an application or even robot integration. Once the material analysis is complete we can help a customer understand its wear ability, cycle time and durability.

Overlooked factors impact auto manufacturer’s bottom-line

We recently worked with a potential customer who had the desire to dispense an adhesive filled with jagged, tabular shaped fillers, to best assemble a new version of their own battery packs. Product developers at this company were designing a new version of their EV battery packs. When selecting an adhesive their driving factor was to make sure it provided the highest thermal conductivity. In this design, the heat transfer from the battery cells, through the material, to the cooling plates is critical to the operation of the completed battery pack.

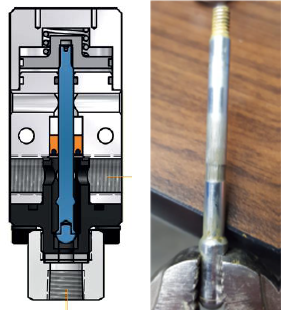

The company contacted Nordson to see what equipment we could deliver. We encouraged them to send their new material to our Material Testing Lab, so we could provide a detailed analysis. After a few months of life testing our engineers learned that while we could dispense this thermal interface material (TIMs), unfortunately it was highly abrasive. On the Mohs hardness scale, the particles in this material ranked at a 9.0 out of 10.0 and composed roughly 80% of the material. The abrasive particles had a significant impact on the wear-life of the dispensing equipment. With an ideal material the average life of dispense components would be roughly 100,000-500,000 dispense cycles but this material was so abrasive, the equipment failed at approximately 4,000 cycles. Our engineers informed the customer that regardless of the equipment they choose, Nordson or a competitor, their maintenance costs would be unsustainable, costing their organization not only significant capital, but also downtime. The company quickly realized it was too late to change since the material was already purchased.

Strategic collaboration is key

How can you make sure this doesn’t happen to your organization in the future? Two words: strategic collaboration. Most product development projects transition through phases and when one phase is complete it’s passed on to the next team, almost like the baton in a relay. Product Engineers design an electric vehicle with a new look, features and functionality. Then, the renderings are passed to the Manufacturing Engineers who must find a way to build it. From the exterior panels to the sealant, this team finds the best cost-effective materials. Once the materials are purchased the next phase must find equipment to assemble the vehicle and maybe even integrate with a robot.

Be a forward thinker. Strategically collaborate with the decision makers from each team. Understand the entire process to work in tandem with one another. Remember each step has a financial impact. Just because your gate is complete think about how it could affect the next. For the auto manufacturer we discussed earlier, if they also would have tested the wear-life of the dispensing equipment and not just the thermal properties of the material, they could have saved production time but more importantly, money.

It’s hard to drive forward if you’re sitting in neutral

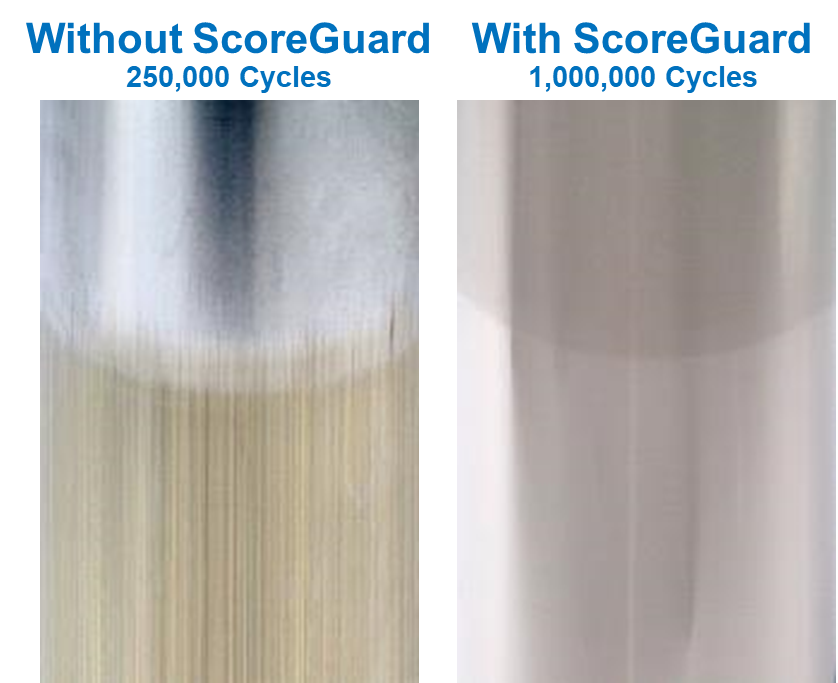

So how did this story end? What did the auto manufacturer do after they learned about the repair time and maintenance costs? Since the TIM was already purchased they have no other choice but to use it and incur the costs; however, their team did partner with the material OEM to reformulate the abrasive material. Now they use a filler with a spherical shape that is less resistant as it moves across the equipment. After sitting in idle for a year the automotive manufacturer was finally able to switch the materials to help lower costs. Nordson was even able to modify our equipment to be able to dispense abrasive TIMs. Now with Nordson’s exclusive ScoreGuard® coated rod, an innovative, trademarked surface finish treatment, that lowers frequency of service and decreases maintenance costs due to higher durability.

Partner with someone who reviews the details

Time is essential, and money doesn’t grow on trees so be strategic when handing both. Leverage technology, ask questions and plan accordingly; sometimes the details are greater than the bigger picture. If you ever encounter a roadblock, give our team a call or schedule a lab test. We’re here to deliver the optimal production for you and your customers.