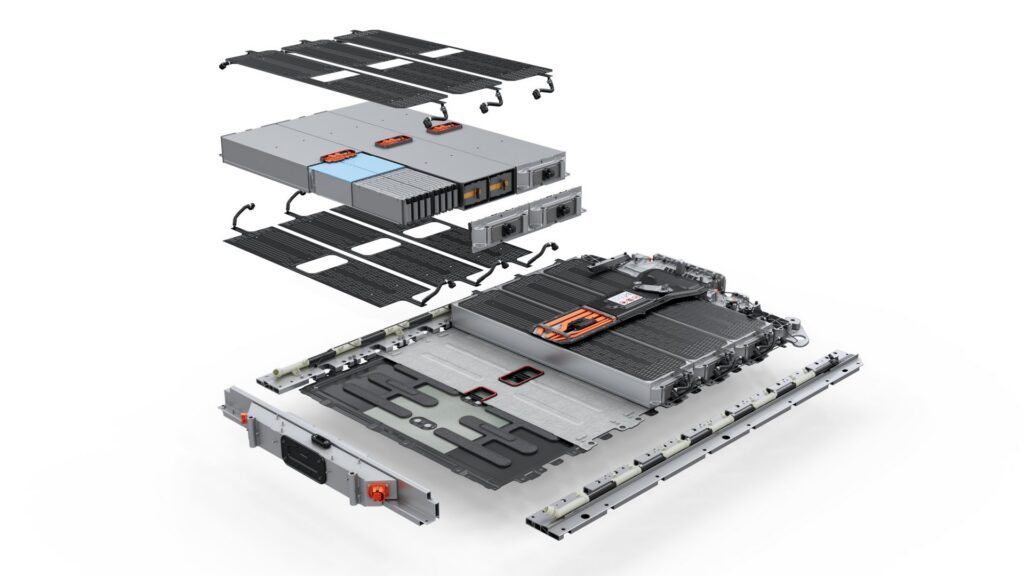

Japanese petroleum company Idemitsu Kosan plans to construct a large-scale production facility for lithium sulfide, an intermediate raw material for the mass production of all-solid-state battery materials

The company will expand its lithium sulfide production capacity to the equivalent of 3 GWh of storage batteries annually and establish an integrated value chain from raw materials to intermediate materials and products. Idemitsu has partnered with Belgian materials firm Umicore to co-develop catholyte materials, which integrate cathode active materials and solid electrolytes.

Lithium sulfide is produced from sulfur components generated as a byproduct in the process of manufacturing petroleum products, and is a key intermediate raw material for the production of solid electrolytes.

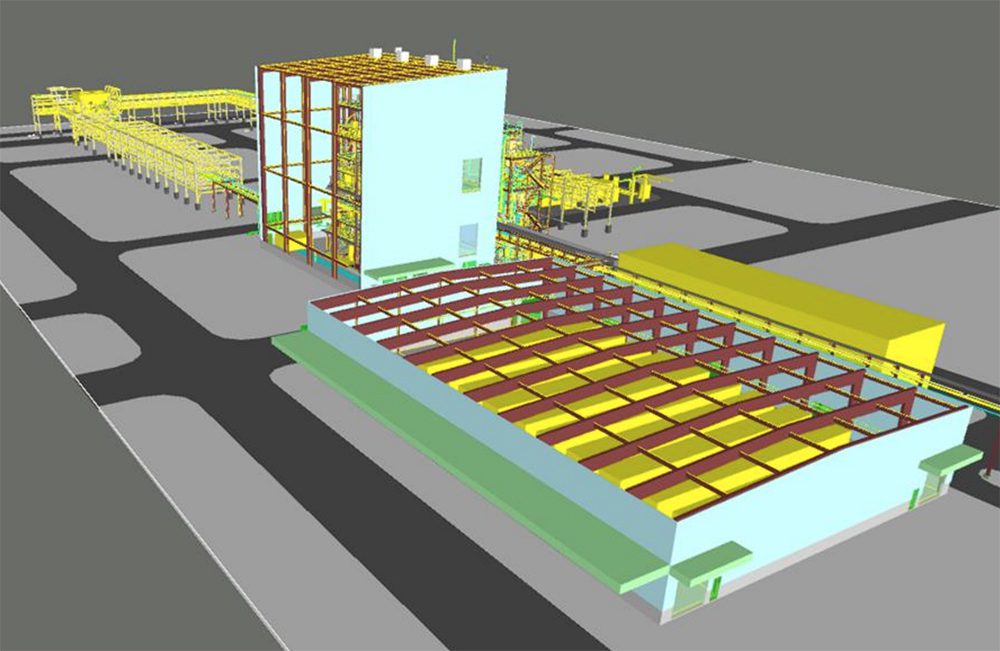

Idemitsu plans to complete construction of the ¥21.3-billion facility within its complex in Chiba, Japan in June 2027. The company aims to commercialize solid-state batteries in 2027-2028 and accelerate the commercialization of solid electrolytes.

The initiative has been approved by the Ministry of Economy, Trade and Industry as a “plan for ensuring supply of storage batteries” and is eligible for a grant of up to ¥7.1 billion.

Idemitsu established mass production technology for lithium sulfide in 1994. It operates two small-scale verification facilities and started the basic design of a large pilot facility in October 2024.

“The decision to construct an Li2S large-scale facility on this occasion was made because mass production of lithium sulfide, an intermediate raw material, is essential for the mass production of solid electrolytes in the future,” the company said.

Source: Idemitsu Kosan