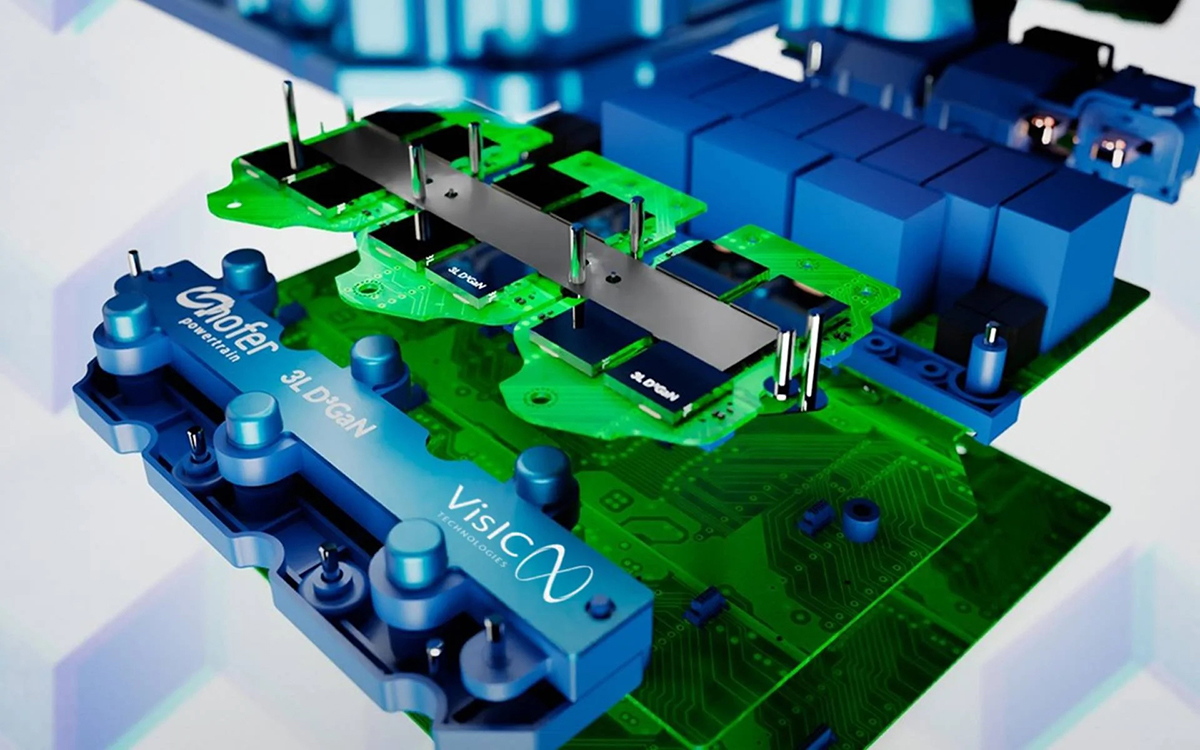

Automotive powertrain maker hofer powertrain is using semiconductor manufacturer VisIC Technologies’s gallium nitride chip in its new inverter.

hofer powertrain has selected the gallium nitride D3GaN Direct Drive D-Mode chip for its new traction inverter. The high-frequency 3-level inverter is designed for 800 V battery systems in automotive applications.

“hofer powertrain’s development paves the way for a breakthrough in GaN inverter performance, which is superior to silicon and silicon-carbide-based designs for high efficiency,” says Senior Product Manager at VisIC Technologies Ilia Bunin.

“Based on the guiding principle ‘develop fast and learn fast,’ hofer powertrain achieves quick results: the team develops a Minimal Viable Product (MVP) to investigate and prove the capability of using 650 V gallium nitride semiconductors in an 800 V 3L NPC inverter application,” says VisIC Technologies.

According to VisIC Technologies, “The new 3-Level GaN (Gallium Nitride) Inverter proves its strong capabilities on the test bench, confirming significantly better switching speed and smaller and lighter package size, reducing total system cost.”

“The upcoming sample stage (A1) has already started, and is expected to perform well in real test conditions with a permanent synchronous motor,” says VisIC . “The team aims to validate and benchmark existing systems using test cycles like the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) and prove its outstanding potential for the entire automotive powertrain.”

Source: VisIC Technologies