Major trends in electronic applications involve operation temperatures above 150 °C, increased power density and longer lifetime. This requires a high melting temperature and fatigue resistance, improved thermal conductivity and reduced electrical resistivity of the connecting material.

Silver-based sintering technology is suited for high operation temperatures due to its pure Ag die attach layer. They also provide excellent thermal conductivity and at the same time a longer lifetime compared to solder.

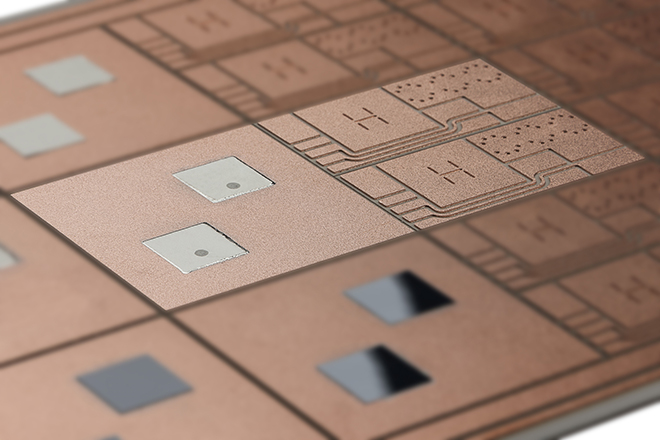

The Heraeus mAgic series sinter material is suitable for power applications on DCB (pressure sintering) as well as for lead frame packages (non-pressure sintering).

The special series for pressure sintering mAgic PE338 (formerly ASP338) shows an increased lifetime up to 10 times more compared to conventional solder in power cycling. As well, it requires lower process pressure compared to other sintering materials.

For non-pressure sintering applications, sinter mAgic DA295 (formerly ASP295) series is a lead-free substitute for high melting point solders. The products are available for the usage in semiconductor applications. These come as print or dispense version and offer high thermal conductivity for lead frame and LED packages.

Use the Heraeus experience to find the best solution for your die attach application.

Heraeus electronics offers a wealth of knowledge in Sinter development and applications that have positioned Heraeus as a leader in Sinter technology. With years of experience developing sinter materials and processes our experts can provide you with hands-on training as well as educate you on implementing sinter into your processes through our sinter seminars.

Key benefits of mAgic sinter paste:

- Up to 10 times higher lifetime compared to solder paste

- Applicable from extremely low to high-temperature range (-55 to 250°C) due to the solid silver layer

- Pure Ag interconnect for operation temperatures up to 250°C

- Enables increasing of power density (system cost reduction) at a total costs level comparable to solder process

- Typical thermal conductivity of 150 W/mK and above

- Zero-halogen formulation

- Fewer process steps due to no flux cleaning, no splattering

- Designed for use in automatic processing with industrial equipment

- Wide process window:

- stencil lifetime great than 8 hours

- both pressure and non-pressure sintering available

- variable process temperatures of 200 – 250°C